The Protolis guide to vacuum casting

This comprehensive guide delves into the intricacies of vacuum casting, a pivotal technology in manufacturing and prototyping.

Method Type

Jump to page content

Page Content

- The basics of vacuum casting

- What is vacuum casting?

- How does the vacuum casting process work?

- How did vacuum casting start?

- What are the benefits of vacuum casting?

- Which materials can be used for vacuum casting?

- Finishing options for vacuum-casted parts

- What are the applications of vacuum casting?

- Best design pratices for vacuum casting

- Cost optimisations for vacuum casting

- Conclusion

The basics of vacuum casting

We will explore its foundational principles and historical evolution as well as its advantages, limitations, and material considerations. Additionally, we will offer insights on design best practices and cost considerations, equipping professionals with the knowledge to harness this technique’s full potential.

What is vacuum casting?

Figure 1: Vacuum casted parts

Vacuum casting (VC) or urethane casting is a commonly used manufacturing process to produce plastic and rubber components. This process harnesses a vacuum to extract air from the mold, promoting the precise formation of the part. It’s particularly beneficial for prototypes and limited production runs, offering a cost-effective and speedy alternative to techniques like injection molding.

The technique shines in delivering high precision and consistency across multiple production runs. It’s well-suited for crafting complex designs with exacting specifications. Despite its strengths, vacuum casting does have its limitations. It is not the go-to method for heat or pressure-sensitive materials, underscoring the importance of selecting the proper process for each material.

In essence, vacuum casting is a reliable choice for projects demanding detailed accuracy and intricate design capabilities. Its application, while specific, offers significant advantages in the right contexts, illustrating its value in the broader manufacturing and prototyping arena.

How does the vacuum casting process work?

Vacuum casting combines cutting-edge design with meticulous mold creation, serving various industries by producing parts with precision and detail. This process requires silicone molds rather than hard/metal molds to produce parts.

Figure 2: Vacuum casting process

Let’s understand the five major steps of the vacuum casting process in detail.

The journey starts with crafting a 3D model of the object. Designers utilize software like AutoCAD, Solidworks, or CATIA to shape the digital blueprint. This model adheres to injection molding principles, ensuring the final product is optimized for vacuum casting.

Next, a master pattern emerges from the 3D model. Additive manufacturing, or 3D printing, has revolutionized this step, making it both efficient and economical. However, designers also use CNC machining to create the master pattern. This pattern serves as the mold’s foundation, embodying the intended part’s precise dimensions and features.

The creation of the silicone mold is the third step. The master pattern is placed suspended in a casting box. Liquid silicone envelops the pattern under vacuum conditions, ensuring bubble-free encapsulation. The mold cures in a preheated oven, a process tailored to the mold’s size. After curing at 40°C for 8-16 hours, the mold is carefully opened to reveal the negative cavity, ready for casting.

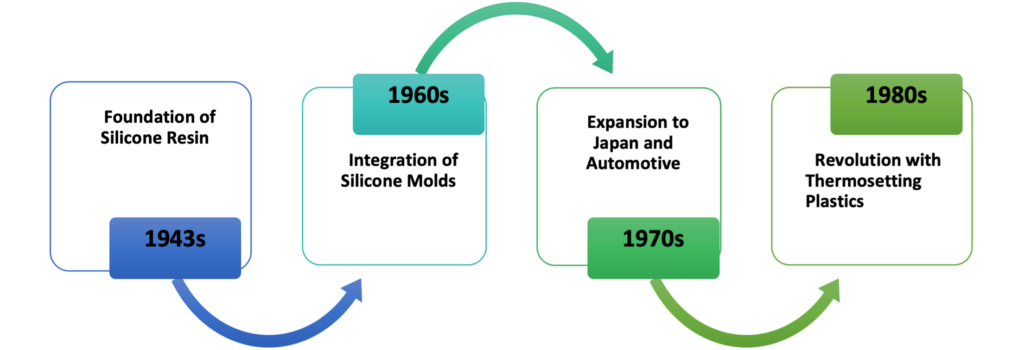

How did vacuum casting start?

The vacuum casting process has a rich history that traces back to mid-20th-century innovations. Its evolution reflects a journey of discovery, adaptation, and refinement, and it is now a staple in modern manufacturing and prototyping.

- 1943: The development of the first silicone resins marked a foundational step, setting the stage for future advancements in casting materials.

- 1960s: Technical universities in Dresden and Cottbus, within the former German Democratic Republic, pioneered the use of silicone molds for plastic vacuum casting. This period was crucial for integrating vacuum casting with flexible molds, previously utilized by restorers and sculptors.

- 1970s: Initially not widespread in Europe, the technology was introduced to Japan. It found significant application in the automotive industry, showcasing the method’s utility in a key sector.

- 1980s: The introduction of thermosetting plastics revolutionized vacuum casting. These materials mimicked the appearance and properties of those used in mass production, enhancing the method’s applicability and efficiency in prototype and small-batch manufacturing.

This historical timeline underlines the method’s evolution from a niche technique to a cornerstone in research and development departments of major production companies worldwide, driven by continuous innovation and adaptation.

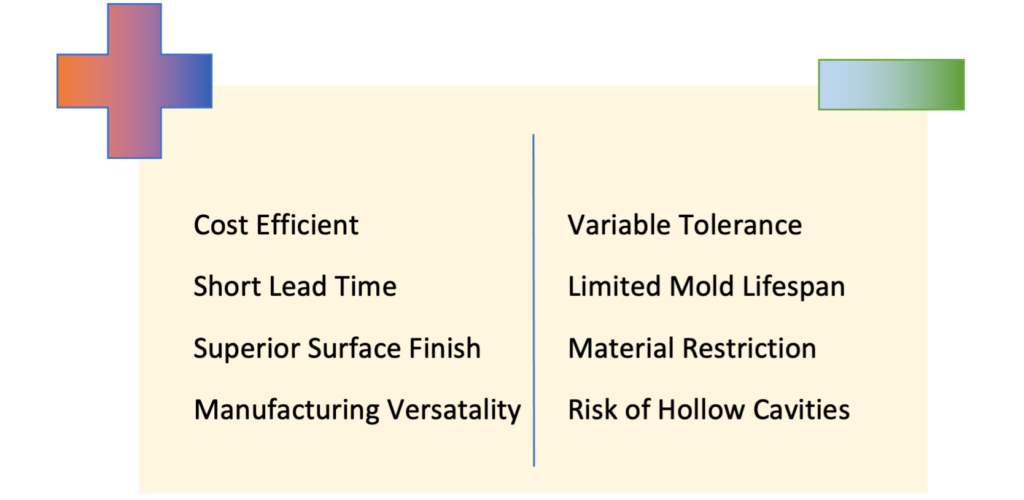

What are the benefits of vacuum casting?

Vacuum casting offers several advantages that cater to the fast-paced demands of modern industry, ensuring products reach the market quicker without compromising on detail or quality.

The advantages of vacuum casting

- Cost rfficiency: Vacuum casting significantly reduces production costs. Silicone molds are quick to produce, often within a day, and can yield 15 to 20 parts. This efficiency surpasses CNC machining and 3D printing in terms of time and cost, especially when compared to the lengthy process of creating molds for injection molding.

- Reduced lead times: The process of creating silicone molds is swift, taking only days compared to the weeks required for steel or aluminum molds. This acceleration in mold creation contributes to faster overall production timelines, enabling quicker project turnaround times.

- Superior surface finish: The initial master model, refined through 3D printing or CNC machining, receives a final surface finish that is precisely replicated by the silicone mold. This method ensures that each part produced mirrors the master with exceptional detail, eliminating the need for repeated surface treatments and further reducing time and costs.

- Manufacturing versatility: This process excels in versatility, accommodating any size or shape a product may require. Its capacity to handle complex designs and intricate features effortlessly sets it apart from more traditional manufacturing methods, offering solutions where others face limitations.

- Material variety and simulation: Using polyurethanes in vacuum casting allows for an impressive range of material properties to be effectively simulated. From the high transparency of PMMA to the robustness of ABS and the flexibility of rubber, vacuum casting meets diverse functional demands. This capability makes it a favorite for low-volume productions needing material-specific characteristics.

- Consistency across parts: Vacuum casting ensures each part maintains uniformity in appearance and functionality, which is crucial for market research and product testing. The fidelity of replication from the master model means every piece produced matches in shape, size, and finish, offering a dependable solution for small-scale production where consistency is critical.

The limitations of vacuum casting

While vacuum casting offers numerous benefits, it also comes with limitations that manufacturers must consider. Understanding these constraints is crucial for choosing each project’s manufacturing process.

Vacuum casting challenges

- Variable tolerances: Silicone molds tend to shrink by an average of 2% after curing, impacting the precision of vacuum-cast parts. Although this shrinkage is critical for mold accuracy, it can result in looser tolerances, making vacuum casting less suitable for highly precise parts.

- Limited mold lifespan: Silicone molds have a relatively short lifespan, typically producing up to 20 parts before degrading. This limitation means new molds must be created for additional batches, increasing time and costs. Consequently, vacuum casting is best suited for low-volume production, where the need for large quantities is not a priority.

- Material restrictions: Vacuum casting is predominantly used with plastic materials, as polyurethanes cannot replicate the properties of metals due to their high melting points. Metals like aluminum, steel, and brass exceed the temperature tolerance of silicone molds, rendering vacuum casting ineffective for metal part production.

- Risk of hollow parts: Incomplete mold filling or trapped air can lead to defects in the cast parts, necessitating re-casting. While vacuum chambers address most bubble-related issues, the quality of the final product heavily relies on the operator’s skill in managing the process.

These limitations highlight the importance of careful process selection in manufacturing. Vacuum casting, with its specific constraints, remains a valuable method for certain applications, particularly in prototyping and small-batch production, where the unique advantages can be fully leveraged.

Which materials can be used for vacuum casting?

The VC process primarily utilizes polyurethane (PU) as its raw material, sourced mainly from two leading suppliers: Sika (Axson) and Heicast. The choice of resin is crucial as it determines the part’s properties and suitability for specific applications.

Materials for vacuum casting are often selected based on their resemblance to thermoplastic grades, with ABS-like resins being particularly favored for their toughness and high-impact resistance. These resins, including PU8150, PU8260, PU8263, PX100, PX118, PX215, UP4280, and UP6160 (noted for their high-temperature resistance), replicate the characteristics of ABS plastic, making them ideal for functional parts and enclosures.

Despite the limited variety of resins available, they effectively meet a broad spectrum of requirements:

- ABS-like materials: For parts needing robustness and impact resistance.

- Transparent resins: Used for parts requiring optical clarity, these can mimic clear, glass-like appearances or be tinted for color and transparency variations.

- High-temperature resins: Essential for heat-composed components, offering resistance to elevated temperatures.

- Flexible resins: Provide elasticity for parts that need bending or flexing during use.

- Silicones: Chosen for their flexibility and biocompatibility, ideal for medical or food-grade applications.

This selection ensures vacuum casting can cater to diverse needs, from transparent and high-temperature components to flexible and food-grade items, showcasing the method’s versatility in material application.

What are the main materials?

Here’s an overview of the primary PU materials available:

| Material Reference | Type of Material | Comment | Natural Color | Max Temperature | Hardness |

| Sika PX 5210 | Similar PMMA | Transparent material resistant to UV. | Transparent | 70-90°C | 83 Shore D |

| Heicast 8263 | Similar ABS – UL94 v0 | Good dimensional stability and UL94-v0 fire resistance. | Beige | 80℃ | 83 Shore D |

| Sika PX 527 | Similar PC | Transparent, good color pigmentation. | Transparent | 80℃ | 80 Shore D |

| Sika PX223 HT | Similar ABS / PA | High temperature resistant, can add 20% GF. | Black | 120℃ | >65 or 80 Shore D |

| SikaPX 5690 | Similar PP/HDPE | Good impact strength, can add 20% GF. | White, Black | 65-85°C | 75 – 83 Shore D |

| Heicast 8400 | Similar TPE/caoutchouc | For flexible parts or overmolding. | White, Black | / | 40-90 Shore A |

| Heicast T0387 | Similar TPE | Flexible parts or over-molding. | Transparent | / | 40-70 Shore A |

| Heicast 8158 | Similar ABS | Good mechanical properties, Japanese FDA compliant. | Beige, Black | 80-100°C | 84 Shore D |

| UX50 | Similar POM | High temperature resistant, good viscosity. | Black, Light Grey, Light Yellow | 150℃ | 87 Shore D |

The combination of materials with overmolding (two-material injection) can enhance the features of a product. For example, by combining a rigid material with another offering more flexibility or a more pleasant feel. This synergy allows for the creation of customized components. It is a strategic approach that meets design criteria and innovates in product development.

Finishing options for vacuum-casted parts

Vacuum casting enables a versatile array of finishes for casted parts, aligning closely with the high standards seen in injection molding processes. Here are the key finishing options available:

Coloring options

- Mass-Dyeing: Integrates color directly into the material during casting for consistent, throughout coloration.

- Painting: Offers customizable color finishes post-production, suitable for specific aesthetic preferences or requirements.

Polishing

- Mirror Polish: Achieves a highly reflective surface, enhancing transparency and visual appeal for clear parts.

Surface treatment

- Chrome Plating: Provides a metallic finish, adding durability and a sleek look to parts, often used for decorative or wear-resistant applications.

Texturing

- Limited VDI Textures: Although the range of textures is narrower compared to plastic injection molding, certain VDI-standard textures can still be applied, offering a variety of surface appearances.

These finishing techniques enhance the aesthetic and functional properties of vacuum-casted parts, providing flexibility in design and application to meet diverse manufacturing needs.

What are the applications of vacuum casting?

Figure 3: Applications of vacuum casting

Vacuum casting serves various industries with its ability to produce high-quality, detailed parts. Here’s how different sectors benefit from this process:

Medical

- Produces complex components like implants and prosthetics, which are crucial for medical applications due to their precision and material versatility.

Automotive

- Crafts detailed automotive parts, including intake manifolds, exhaust systems, and body panels, benefiting from the process’s accuracy and repeatability.

Food

- Creates molds, packaging components, and intricate shapes needed in food production, leveraging the process’s ability to use food-safe materials.

Consumer goods

- Manufactures toys and sporting equipment, where the process’s precision ensures high-quality consumer products.

While vacuum casting parallels plastic injection in its applicability across similar industries, it i’s primarily suited for small-scale production due to its limitations in quantity. This makes it an ideal choice for prototypes and limited runs, where its advantages in cost, speed, and flexibility can be fully utilized.

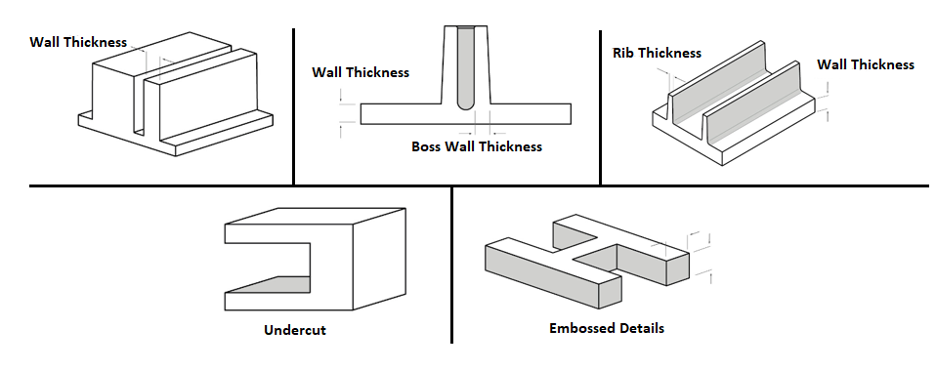

Best design pratices for vacuum casting

In vacuum casting, balancing expenditure with product quality is essential. In this section, we’ll explore some practical design tips to achieve a winning combination of project cost and the quality of the finished parts.

Design tips for vacuum casting parts

Effective design practices are paramount when preparing parts for vacuum casting. This section delves into critical considerations that ensure casted components’ functionality, durability, and aesthetic quality.

Figure 4: Design tips for vacuum casting

The following guidelines highlight the importance of thoughtful design to optimize the casting process:

Vacuum casting offers a general tolerance of +/- 0.3 mm or 0.010 in for the initial dimension and 0.05 mm or 0.002 in for every additional 25 mm or 1 in. While tighter tolerances are possible for essential features, planning for gaps to ensure successful final assembly is wise. We at Protolis analyze the tolerances and assembling gaps during DFM. We will give you our recommendations.

Including a draft angle of at least 0.5° on surfaces is not mandatory but recommended to facilitate part demolding and extend the silicone mold’s lifespan.

Aim for a consistent wall thickness to reduce the risk of deformation. A minimum thickness of 1 mm is standard, with allowances for thinner walls on smaller parts and adjustments for more significant parts.

Introducing ribs to large flat areas enhances strength and reduces warping. Rib thickness should ideally be no more than 60% of the wall thickness, and the height should be limited to less than three times the thickness to avoid sink marks.

Integrate bosses into designs for fasteners or threaded inserts, supported by ribs for stability. Maintain the boss wall thickness below 60% of the part’s wall thickness, with a base radius of at least 25% of the part’s wall thickness to avoid sink marks.

Undercuts are easily manageable in vacuum casting and can be designed without complex additional movements. However, for parts intended for subsequent injection molding, the design of these undercuts will have a significant impact. We recommend considering them from the outset.

To maximize part strength and stability, introduce fillets to internal corners, recommending a radius of at least 3 mm. This practice not only enhances the mechanical properties of the part but also facilitates the flow of material during the casting process, reducing stress concentrations that can lead to cracks or fractures, thereby improving the overall durability and quality of the final product.

Vacuum casting can include through holes and threads using inserts for precision. While adding these features directly to the master pattern is possible, using inserts is more cost-effective and provides better functionality for prototypes.

For text and logos to be clearly visible when recessed or embossed, they should have a minimum depth and height of 1 mm, with a width of at least 1 mm. Maintain a gap of 1mm between characters for optimal legibility and definition in the final part.

By adhering to these design tips, engineers and designers can leverage vacuum casting’s versatility, achieving prototypes and small-batch productions that closely align with their vision and specifications.

Cost optimisations for vacuum casting

It’s important to understand and account for the various factors that determine the cost of vacuum casting projects. This section explores these factors in detail, offers practical tips to reduce costs, and compares the price of vacuum casting to other manufacturing processes.

Reducing the cost of vacuum casting

Reducing costs in vacuum casting doesn’t mean cutting corners. It’s about design optimization and leveraging expertise to balance quality and expense best. Let’s explore pragmatic approaches to minimizing costs without compromising the integrity of the final product.

Material selection plays a pivotal role in controlling vacuum casting costs. Choosing the right resin based on the product’s functional requirements can lead to significant savings without compromising quality or durability.

Simplifying designs can directly impact the cost-effectiveness of vacuum casting. Eliminating non-essential complexities can reduce the need for specialized molds or additional processing, thus lowering overall expenses.

An optimized wall thickness ensures material efficiency and structural integrity, preventing issues like warping. Consistency in wall thickness results in material savings, faster curing times, and streamlined production.

Crafting a mold that maximizes material usage and minimizes waste is critical to cost reduction. A well-designed mold can produce multiple parts at once, reducing the likelihood of defects.

Prototyping is an essential investment in the vacuum casting process. It allows for the early detection and correction of design flaws, saving costs that would be much higher if discovered during full production.

Choosing an experienced manufacturer like can offer cost benefits. A manufacturer specializing in vacuum casting can provide insights into economical production without compromising the product’s quality.

Strategic choices in the design and production phases are key to cost-effective vacuum casting, ensuring a balance between quality, functionality, and economic efficiency.

How the cost of vacuum casting compares to other processes

Comparing the cost of vacuum casting to other manufacturing processes like injection molding, CNC machining, and 3D printing involves considering several variables such as production volume, material cost, labor, and the level of detail required. Here’s a brief comparison:

Vacuum casting vs. injection molding

- Vacuum casting is typically more cost-effective for small production runs due to lower initial setup and mold costs.

- Injection molding [1] has higher initial costs but becomes more economical at high volumes where the cost per part decreases significantly.

Vacuum casting vs. CNC machining

- CNC machining[1] requires no mold, which means no initial mold cost, but the material wastage and machine time can make it more expensive for small to medium runs.

- Vacuum casting, with its reusable silicone molds, can be more cost-efficient for small batches, offering a quicker turnaround and less waste.

- We generally consider that vacuum casting is more cost-effective for production runs of fewer than 200 to 300 pieces.

Vacuum casting vs. CNC machining

- 3D printing [1] has low initial costs and is economical for small runs or complex prototypes due to its additive process.

- For slightly larger quantities, vacuum casting might offer a better cost per part due to the reusability of molds and the production speed.

| Manufacturing Process | Volume Range | Ideal Use Case |

| Vacuum Casting | 50 to 200 parts | Suitable for low to medium-volume production where the cost and efficiency balance is critical. Offers flexibility in part complexity and material selection. |

| 3D printing | Very low to low volume production (1 to 500 parts) | Best for very low volume production due to no need for tooling or molds, offering rapid prototyping and customization flexibility. |

| CNC Machining | Varied, efficient for up to 100-500 parts | Excel in producing parts with high precision and surface finishes. It is ideal for very low- and medium-volume production, depending on the complexity and material requirements. |

| Injection Molding | 500 – 1,000 parts and beyond | Most cost-effective for medium to high volume production due to high initial tooling costs spread over large quantities, offering various materials and high-quality finishes. |

In essence, vacuum casting often occupies a sweet spot for small to medium quantities, offering a cost-effective solution with good quality and reasonable production speed, especially when compared to the higher setup costs of injection molding or the slower production rates and potentially higher material costs of CNC machining and 3D printing for equivalent quantities.

Conclusion

Vacuum casting distinguishes itself by offering precision, versatility, and cost efficiency, which are particularly valuable for projects requiring intricate detail and material specificity. Key findings underscore the importance of thoughtful material selection and design simplification to optimize costs and ensure product integrity. By maintaining uniform wall thickness, judiciously incorporating features like ribs and bosses, and considering embossed details for clarity, designers can leverage vacuum casting’s full potential.

If you need expert vacuum casting services[2] , rest assured that our commitment to quality, precision, and customer satisfaction will bring your innovative designs to life. Contact us [3] and discover how Protolis can help you achieve your manufacturing goals with unparalleled efficiency and cost-effectiveness.