The Protolis guide to sheet metal fabrication

Unlock the full potential of your manufacturing processes with our comprehensive guide to sheet metal fabrication. Dive into the details of transforming flat metal sheets into high-quality, functional parts and products. From cutting-edge techniques to best design practices, this guide is crafted to address the unique challenges faced by industry professionals. Whether you’re seeking to optimize efficiency, enhance precision, or reduce costs, our detailed insights will empower you to achieve unparalleled results.

Method Type

Jump to current chapter

Current Chapter

- The basics of sheet metal

- How does the sheet metal fabrication process work?

- Sheet metal fabrication techniques

- What are the benefits of sheet metal fabrication?

- What are the limitations of sheet metal fabrication?

- Materials for sheet metal fabrication

- How to choose the right materials for sheet metal fabrication?

- Surface finishing options for sheet metal fabricated parts

- What are the applications of sheet metal fabrication?

- Best design pratices for sheet metal

- Uniform wall thickness

- Bend Radius

- Holes and slots

- Hems and curls

- Notches and tabs

- Countersinks

- Riveting and welding

- Cost optimisations for sheet metal

- Conclusion

The basics of sheet metal

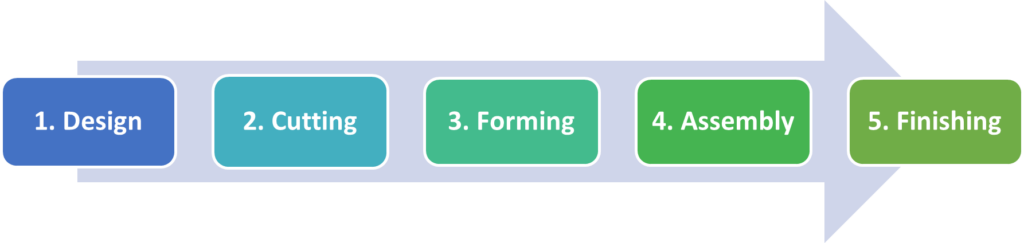

Figure 1: Sheet metal fabrication process

Sheet metal fabrication is the process of transforming flat metal sheets into functional parts and products. This involves cutting, forming, and joining/assembling metal sheets. Various metals are used in this process, including steel, aluminum, stainless steel, brass, copper, and zinc. The thickness of sheet metal ranges from 0.15 to 6.25 mm (0.006 to 0.25 in.).

Manufacturers utilize diverse techniques to create sheet metal parts. These techniques are chosen based on the product specifications determined during the design phase. Fabrication methods can vary depending on the required features of the final product.

For example, stamping and laser cutting ensure precise shapes and durability when producing an automotive panel. In manufacturing HVAC ducts, fabricators use bending and welding to create airtight and robust structures.

This process is valued for its ability to produce durable components. It supports both small-scale prototypes and large-volume production runs. This versatility makes it a preferred choice in various industries, from automotive to aerospace.

How does the sheet metal fabrication process work?

The sheet metal fabrication process includes five main steps: designing, cutting, forming, assembly, and finishing.

In this step, engineers create detailed plans and specifications for the desired product. This stage involves CAD software like AutoCAD and SolidWorks to design the parts accurately.

Next, the sheet metal undergoes cutting. This step ensures the metal sheets are sized correctly for further processing. Methods like laser cutting, shearing, and waterjet cutting are commonly used for precise cuts. We will discuss each cutting process in the next section.

Next is the forming process. This step shapes the cut metal sheets using bending, punching, rolling, or curling. These techniques give the metal its desired 3D shapes. For instance, bending creates angles and curves, while rolling produces cylindrical shapes.

Then comes the assembly or joining step. Here, the individual parts are joined together by riveting or welding. This step ensures the final product is robust and functional. Riveting is often used for parts that need to be disassembled later, while welding provides a permanent bond.

The final step, finishing, involves processes like painting, coating, or polishing. This ensures the product meets both aesthetic and functional standards while enhancing its durability. For instance, it can improve appearance and resist corrosion.

This complete industrial sheet metal fabrication process is essential for creating high-quality parts. Now, let’s examine each manufacturing technique in detail.

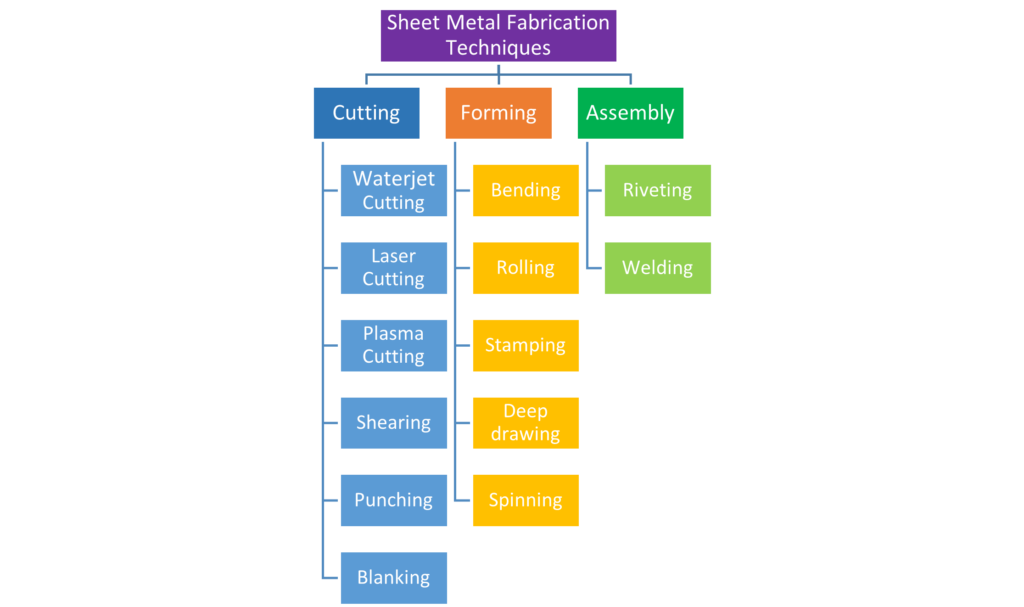

Sheet metal fabrication techniques

Sheet metal fabrication involves various techniques to transform raw metal into finished products. There are three major techniques, each with specific methods to achieve the desired outcome.

1 – Sheet metal cutting

Sheet metal cutting transforms raw metal sheets into specific shapes. This process can be performed using various techniques, including:

- Waterjet cutting

- Laser cutting

- Plasma cutting

- Shearing

- Punching

- Blanking

Waterjet cutting

Figure 2: Waterjet cutting

Waterjet cutting uses a high-pressure stream of water to cut metal sheets. It operates at around 60,000 psi (4136 bar), delivering a velocity of about 610 m/s. There are two types: normal waterjet cutting and abrasive waterjet cutting.

- Normal waterjet cutting is ideal for soft materials like fabrics, rubber, or metal foils.

- Abrasive waterjet cutting, which includes added abrasives, is suitable for hard materials like carbon steel, stainless steel, aluminum, and copper.

This process provides excellent surface finishes without burrs or heat distortions. However, high pressures can cause bending near the cut area, necessitating proper support for the component.

Laser cutting

Figure 3: Sheet metal laser cutting

Laser cutting is a thermal process that melts metals using focused laser beams. It involves two sub-processes. The first focuses a high-powered laser beam on the sheet metal, vaporizing the material. Simultaneously, a cutting nozzle supplies nitrogen or oxygen gas, which protects the processing head and removes excess material.

Laser cutters handle various metals, from stainless steel to mild steel, with metal thicknesses ranging between 20 mm (0.78 in.) to 40 mm (1.6 in.), depending on the laser’s power. Reflective metals like aluminum are more challenging, but fiber lasers can manage them.

This cutting process suits industrial applications due to its flexibility, precision, and efficiency. However, it requires high energy and gas consumption, resulting in high investment costs and strict safety requirements.

Plasma cutting

Figure 4: Plasma arc cutting in metal fabrication

Plasma cutting uses a high-temperature, ionized gas stream to melt and cut metal. It works effectively on electrically conductive metals. This method is ideal for cutting material up to 50 mm (2 in) thick.

While not as precise as laser or waterjet cutting, plasma cutting is faster and highly repeatable. It also supports automation for efficient high-strength metal cutting with lower heat input. However, plasma cutting has high power consumption and can be noisy.

Shearing

Figure 5: Shearing in sheet metal fabrication

Shearing cuts straight lines on flat metal by applying a shearing force. This process is perfect for high-volume applications. It works well with soft materials like aluminum, mild steel, and brass.

This process is cost-effective for producing thousands of parts quickly. However, it creates burrs and deformation, making it unsuitable for applications needing a clean finish.

Blanking

Figure 6: Sheet metal blanking

Blanking removes a piece of sheet metal from a larger sheet using a punch and die. The punch forces the metal through the die, cutting out the desired shape. The removed piece, known as the “blank,” is the final component, while the leftover sheet is scrap.

This metal-cutting process is cost-effective for producing custom parts with high accuracy and repeatability. It offers excellent dimensional control but can be slower and more expensive in tooling than punching.

Punching

Figure 7: Punching metal sheets

Punching creates simple shapes in sheet metal by applying shear force. However, unlike blanking, the material removed from the hole is considered scrap, and the remaining sheet forms the final component. This process is faster and more efficient for creating numerous holes quickly. Standard shapes like circles and squares are commonly punched, but custom dies can create complex shapes.

Sheet metal punching provides clean and precise holes without the risk of thermal distortion since it does not involve heat. Despite its efficiency, preparing the punch and die sets can be time-consuming and requires careful alignment.

At Protolis, we offer all of the above-mentioned sheet metal cutting technologies. We can assist you with any cutting design for your sheet metal project, ensuring precision and efficiency.

2 – Sheet metal forming

Forming can be achieved by different methods, including:

- Bending

- Rolling forming

- Stamping

- Deep drawing

- Spinning

Bending

Figure 8: V-bending metal sheet

Bending deforms metal into desired angles and shapes using force. This process is typically carried out with press brakes. A press brake uses a punch and a die to bend sheet metal precisely.

This forming process is suitable for malleable metals like mild steel, spring steel, aluminum 5052, and copper. Metals such as aluminum 6061, brass, bronze, and titanium pose more challenges.

There are primarily two basic techniques for sheet metal bending, but many types of bending are used.

V-bending includes three subtypes:

- Bottoming: compressing the sheet against the die for precise angles.

- Coining: offers higher accuracy.

- Air bending: partial contact with the die, faster but less precise.

Roll bending involves:

- U-bending: similar to V-bending, but with a U-shaped die.

- Rotary bending: used for scratch-free parts.

- Wipe bending: bends or rounds sheet edges using a punch.

This process is cost-effective for low to medium-volume productions and yields parts with excellent mechanical properties. However, spring back can affect the final bend angle, requiring adjustments and considerations during the design phase.

Rolling forming

Figure 9: Sheet metal cold rolling

Rolling is a metalworking process primarily used to create cylindrical shapes in sheet metal. It involves passing the metal between two or more rollers with a specific profile to deform the sheet. The process uses machines called rollers.

These techniques are used to produce a variety of parts, including cones for industrial applications (e.g., funnels, machine components), conical sections for structural parts, and decorative elements for various industries (e.g., architectural or artistic pieces).

Stamping

Figure 10: Stamped automotive part

Sheet metal stamping is a cold-forming process using presses and dies to shape materials. It works with various metals, including stainless steel, carbon steel, aluminum, brass, and copper. Stamping combines cutting and forming techniques like bending, punching, embossing, and flanging to produce complex components quickly.

This process is cost-effective due to its speed, reduced labor, and lower maintenance costs for stamping dies. Automation ensures consistent, high-quality parts with excellent repeatability. However, the high cost of presses and difficulty in changing dies during production are disadvantages.

Deep drawing

Figure 11: Sheet metal deep drawing

Deep drawing is a metal forming process used to create deep, hollow shapes from flat metal sheets, such as cups, cans, or containers. The process involves pressing a sheet into a die cavity using a punch, stretching the material to form the desired deep shape without breaking it.

The difference between deep drawing and stamping is that stamping is a broader term that encompasses various operations like blanking, punching, bending, and embossing. Stamping typically creates shallower shapes, while deep drawing specifically refers to forming deep, hollow parts.

Spinning

Figure 12: Sheet metal curling

Spinning is used to create axially symmetric parts by rotating a flat metal disc (or blank) on a lathe or spinning machine. As the blank spins, a forming tool (or roller) applies pressure to the metal, gradually shaping it against a form (or mandrel) into a desired shape, often cylindrical or conical. This process can produce complex, hollow shapes without seams.

3. Sheet metal assembly

The sheet metal assembly process is crucial for creating durable and functional products. This stage ensures that individual parts are securely joined, maintaining structural integrity and meeting design specifications. The two primary methods for assembling sheet metal components are;

- Mechanical fasteners

- Welding

Mechanical fasteners

Figure 13: Sheet metal riveting

Mechanical fasteners, such as bolts, screws, and rivets, join sheet metal components semi-permanently. Riveting is a common method that begins with drilling holes in the metal pieces to be joined. The rivet is inserted, and its tail is deformed by smashing and securing the pieces together.

Riveting can be performed using two techniques: hot riveting and cold riveting. Hot riveting applies heat between 1000-1100°C to steel rivets over 10 mm (0.39 in.) in diameter, while cold riveting is suited for non-ferrous metals under 10 mm (0.39 in.) in diameter. This method is efficient and cost-effective but adds weight to the component and may weaken the metal due to the drilled holes.

Welding

Figure 14: Sheet metal welding

Welding joins metal sheets using heat, pressure, or both. It melts the base metals and often adds filler material to create a strong joint. Several welding techniques are used in sheet metal fabrication:

- Stick welding (SMAW): This process uses an electrode stick to create an electric arc, producing temperatures over 6300°F. It is suitable for high-speed welding and works on AC and DC power sources. However, it can damage thin metals due to the high temperatures.

- MIG welding (GMAW): This technique uses a continuous wire electrode and shielding gas. The wire melts to join the metals, while the gas protects the weld pool. Metal Inert Gas welding creates high-quality welds quickly and can be automated. It is not suitable for thick metals or outdoor welding.

- TIG welding: This process uses a tungsten electrode and an inert gas to protect the weld area. Tungsten Inert Gas welding is ideal for non-ferrous metals like aluminum, copper, and titanium. It offers high weld control, producing clean, strong welds. However, it requires skilled professionals due to its complexity.

Each method in the sheet metal assembly process has its advantages and applications, ensuring the final product meets the necessary standards of strength and durability.

At Protolis, we utilize state-of-the-art machines for all sheet metal fabrication processes. Our advanced equipment ensures precision and efficiency in cutting, forming, and assembly. Whether you need custom prototypes or high-volume production, we deliver exceptional quality and reliability for all your sheet metal fabrication needs.

The past, present, and future of sheet metal fabrication

- The past

Sheet metal fabrication has ancient roots, dating back to 1400 B.C. when Egyptians used gold to create jewelry and tools. By the 5th century B.C., Greeks and Romans developed techniques to produce weapons and armor. In the Middle Ages, blacksmiths advanced metalworking skills, crafting armor and structural components.

The Industrial Revolution in the 18th century marked a significant shift with the introduction of machines like rolling mills and steam hammers, revolutionizing metal production and fabrication processes. By the late 19th century, advancements in metallurgy and machinery enabled mass production of sheet metal parts, setting the foundation for modern fabrication techniques.

- The present

Today, sheet metal fabrication is integral to various industries, including automotive, aerospace, and construction. The 20th and 21st centuries have seen significant technological advancements. Computer nNumerical cControl (CNC) machines, laser cutters, and automated welding systems have transformed fabrication, increasing precision, efficiency, and speed.

Innovations in software, such as cComputer-aAided dDesign (CAD) and cComputer-aAided mManufacturing (CAM), have streamlined the design and production processes. Materials science has also evolved with the development of new alloys and composites that enhance the properties and applications of sheet metal.

- The future

The future of sheet metal fabrication looks promising, driven by continued advancements in technology. Additive manufacturing, or 3D printing, is expected to complement traditional fabrication methods, enabling complex designs and reducing material waste. Robotics and automation will further enhance precision and productivity, while artificial intelligence (AI) and machine learning will optimize processes and predictive maintenance.

Sustainable practices will also gain prominence, with an emphasis on recycling and eco-friendly materials. As industries continue to evolve, sheet metal fabrication will adapt to meet the demands of new applications and innovations, ensuring its relevance and growth.

What are the benefits of sheet metal fabrication?

Sheet metal fabrication offers numerous advantages, making it a preferred method in various industries. This process transforms raw metal sheets into functional products with precision and efficiency.

Sheet metal parts are known for their durability and strength. Metals like steel, aluminum, and titanium are resistant to corrosion, heat, and weather conditions. This makes them ideal for constructing robust components that endure harsh environments.

For instance, stainless steel, due to its chromium content, forms a passive layer that prevents rusting. This inherent strength reduces the need for frequent replacements, ensuring long-lasting performance.

Sheet metal fabrication is highly versatile, allowing for the creation of a wide range of products. It supports various processes such as cutting, bending, rolling, stamping, and welding. This versatility enables the production of everything from small precision parts to significant structural components.

The ability to work with different metals, including steel, aluminum, copper, and brass, further enhances its adaptability. For example, aluminum is lightweight and malleable, making it suitable for automotive and aerospace applications.

Modern sheet metal fabrication techniques offer high precision and accuracy. CNC machines, laser cutters, and CAD/CAM software ensure that parts are manufactured to exact specifications.

This precision is crucial in industries like aerospace and medical device manufacturing, where tolerances are extremely tight. CNC machines can repeatedly produce parts with minimal deviation, ensuring consistency and quality in mass production.

Sheet metal fabrication is cost-effective, especially for large production runs. The processes involved, such as stamping and punching, are efficient and minimize material waste. Additionally, the durability of sheet metal reduces maintenance and replacement costs.

Automated machines like CNC and robotic welders increase production speed and reduce labor costs, making manufacturing more economical. For example, the initial investment in a CNC machine is offset by its high production rate and low operational costs over time.

Customization is another significant benefit of sheet metal fabrication. Manufacturers can tailor designs to meet specific requirements, offering flexibility in production. Custom tooling and dies allow for unique shapes and complex designs.

This is particularly useful in industries such as automotive and architecture, where bespoke components are often needed. The ability to produce prototypes and make adjustments quickly accelerates the development process and reduces time-to-market.

Sheet metal fabrication is environmentally friendly. Metals like steel and aluminum are recyclable, reducing waste and conserving natural resources. The fabrication process itself can be optimized to minimize energy consumption and emissions.

Advanced techniques, such as waterjet cutting and laser cutting, reduce scrap and improve material utilization. By recycling and reusing metals, manufacturers contribute to a circular economy, promoting sustainability in the industry.

These were the top six advantages of sheet metal fabrication, highlighting its durability, versatility, precision, cost-effectiveness, customization, and sustainability. These benefits make it an essential process in modern manufacturing.

What are the limitations of sheet metal fabrication?

While sheet metal fabrication offers various advantages, it also has limitations that can affect its application in various industries. Understanding these limitations is essential for making informed decisions in manufacturing processes.

● High initial costs

One of the primary limitations of sheet metal fabrication is the high initial cost. Setting up a fabrication facility requires substantial investment in machinery, such as CNC machines, laser cutters, and press brakes. These machines are expensive and require significant capital outlay.

Additionally, the cost of tooling, such as dies and molds, can be high, especially for custom designs. The initial setup costs can be a barrier for small businesses or startups looking to enter the market. While the long-term benefits and efficiencies can offset these costs, the upfront investment is a considerable financial commitment.

● Material limitations

Not all materials are suitable for sheet metal fabrication. Metals with high brittleness, such as cast iron, or those with low malleability, like some grades of aluminum, are challenging to work with. These materials can crack or break during the bending and forming processes.

Moreover, certain metals, like titanium, require specialized equipment and techniques due to their unique properties. This limitation restricts the range of materials that can be effectively used in sheet metal fabrication, potentially narrowing the scope of projects and applications.

● Complexity of designs

While sheet metal fabrication allows for the creation of complex shapes, there are inherent limitations in the level of detail and intricacy that can be achieved. Extremely intricate designs with fine details can be challenging to fabricate without advanced and expensive machinery. Achieving precise tolerances can be challenging due to factors like spring back in bending processes. Complex designs may require multiple fabrication steps, increasing production time and costs. This limitation makes sheet metal fabrication less suitable for projects requiring high precision and intricate details.

● Thickness constraints

The metal fabrication process is generally limited to working with materials of certain thicknesses. Very thin sheets can be challenging to handle and may deform or tear during fabrication. On the other hand, very thick sheets require more powerful machinery and can be challenging to form and cut accurately. This constraint limits the range of applications for sheet metal fabrication, particularly in industries that require extremely thin or thick metal components.

For example, fabricating thin metal foils for electronics or thick metal plates for heavy machinery may require specialized processes outside the scope of conventional sheet metal fabrication.

● Longer production times

The adaptability of 3D printing is unmatched. It supports a wide range of materials, including plastics, metals, and composites, allowing for creating parts with specific properties tailored to their application. This versatility extends to production, where manufacturers can easily switch between materials and models without tooling changes, efficiently accommodating custom orders and small batches.

The fabrication process of sheet metal can involve longer production times, especially for complex parts. Multiple steps such as cutting, bending, and assembling are often required, each adding to the overall production time.

Advanced techniques and precision requirements can further extend the manufacturing process. This can be a drawback for projects with tight deadlines or those requiring rapid turnaround. While automation and modern machinery can speed up production, the complexity of the tasks involved often leads to longer lead times compared to other manufacturing processes.

| Sheet metal fabrication process | |

| Benefits | Limitations |

| Durability – Sheet metal parts are solid and durable, resisting corrosion, heat, and weather. | High initial costs – Setting up a fabrication facility requires significant investment in machinery and tooling. |

| Versatility – Supports various processes like cutting, bending, rolling, stamping, and welding. | Material limitations – Not all materials are suitable; some can crack or break during fabrication. |

| Precision and accuracy – CNC machines and CAD/CAM software ensure high precision and consistency. | Complexity of designs – Extremely intricate designs require advanced and expensive machinery. |

| Cost-effectiveness – Efficient processes minimize material waste and reduce labor costs. | Thickness constraints – Difficulties handling very thin or very thick sheets, requiring specialized machinery. |

| Customization – Allows for tailored designs and quick adjustments, which are helpful for bespoke components. | Longer production times – Complex parts require multiple steps, extending production times. |

| Sustainability – Metals are recyclable, and advanced techniques reduce scrap and improve material utilization. | |

Understanding these benefits and limitations will guide you in better decision-making during the manufacturing process.

Materials for sheet metal fabrication

Metal fabrication utilizes a variety of materials, each chosen for its unique properties and suitability for different applications. Common materials include steel, aluminum, copper, brass, and titanium. These metals are selected based on their strength, malleability, corrosion resistance, and conductivity.

The choice of material depends on the specific requirements of the project, such as durability, weight, and environmental factors. Different metals allow for flexibility in design and functionality, making metal fabrication a versatile manufacturing process used across various industries.

Now, let’s talk about these materials in detail.

Aluminum

Aluminum is a popular choice in sheet metal fabrication due to its excellent formability and lightweight nature. It has a melting temperature of approximately 660°C (1220°F) and a density of 2.7 g/cm³. Aluminum alloys, such as 5052 and 6061, are commonly used due to their balance of strength and flexibility.

With a hardness range of 30-95 HB (Brinell hardness) and tensile strengths between 70-700 MPa, aluminum is suitable for various applications, from automotive parts to aerospace components. Its corrosion resistance makes it ideal for environments exposed to moisture and chemicals.

Copper

Copper’s excellent conductivity and formability make it valuable in electrical and thermal applications. It has a melting temperature of around 1085°C (1985°F) and a density of 8.96 g/cm³. Copper alloys like C110 (pure copper) and C101 (oxygen-free copper) are frequently used in fabrication.

The material exhibits a hardness of 35-110 HB and tensile strengths ranging from 200-400 MPa. Copper’s high malleability allows it to be easily shaped into intricate designs. Its superior electrical conductivity makes it indispensable for electrical wiring, connectors, and other electronic components.

Steel

Steel is widely used in sheet metal fabrication due to its versatility and strength. It melts at approximately 1370°C (2500°F) and has a density of 7.85 g/cm³. Common alloys include carbon steels like A36 and high-strength low-alloy steels such as A572. Steel offers a hardness range of 120-200 HB and tensile strengths from 250-700 MPa, depending on the alloy.

It is known for its high tensile strength and durability, making it suitable for construction, automotive, and heavy machinery applications. Steel’s formability allows for extensive use in various structural and decorative applications.

Stainless steel

Stainless steel combines corrosion resistance with strength, making it ideal for demanding environments. It has a melting temperature of around 1400°C (2550°F) and a density of 8.0 g/cm³. Alloys such as 304 and 316 are preferred in fabrication for their excellent mechanical properties and resistance to rust.

Stainless steel’s hardness ranges from 150-600 HB, with tensile strengths between 515-1035 MPa. Its formability and aesthetic appeal make it suitable for kitchen equipment, medical devices, and architectural elements. Protolis uses advanced techniques to fabricate high-quality stainless steel components.

Brass

Brass, an alloy of copper and zinc, is valued for its machinability and corrosion resistance. It has a melting temperature of about 930°C (1710°F) and a density of 8.4 g/cm³. Common brass alloys used in sheet metal fabrication include C260 and C268. Brass exhibits a hardness of 50-100 HB and tensile strengths ranging from 200-500 MPa.

Its formability and attractive finish make it ideal for decorative items, musical instruments, and plumbing fixtures. Brass’s low friction properties benefit applications requiring smooth, precise movements.

Titanium

Titanium offers an excellent strength-to-weight ratio and high corrosion resistance. It melts at approximately 1668°C (3034°F) and has a density of 4.5 g/cm³. Titanium alloys like Grade 2 and Grade 5 (Ti-6Al-4V) are commonly used in fabrication. Titanium is suitable for aerospace, medical, and military applications with a 150-400 HB hardness range and tensile strengths from 240-1100 MPa.

Its formability is lower compared to other metals, but its exceptional properties make it indispensable for high-performance applications. Protolis excels in fabricating complex titanium components with precision.

Magnesium

Magnesium is the lightest structural metal used in sheet metal fabrication. It has a melting temperature of about 650°C (1202°F) and a 1.74 g/cm³ density. Common magnesium alloys include AZ31 and AZ61, known for their excellent formability. Magnesium’s hardness ranges from 30-100 HB, with tensile strengths between 150-300 MPa.

Its lightweight nature makes it ideal for aerospace, automotive, and electronics applications, where weight reduction is crucial. Despite its lower tensile strength, magnesium’s ease of machining and excellent strength-to-weight ratio are highly valued in various industries.

| Material | Alloys | Properties | Melting Point | Hardness (HB) | Tensile Strength (MPa) | Price |

| Aluminum | 5052, 6061 | Lightweight, corrosion-resistant | 660°C | 30-95 | 70-700 | $$ |

| Copper | C110, C101 | Excellent conductivity, malleable | 1085°C | 35-110 | 200-400 | $$$$ |

| Steel | A36, A572 | Versatile, strong | 1370°C | 120-200 | 250-700 | $ |

| Stainless Steel | 304, 316 | Corrosion-resistant, strong | 1400°C | 150-600 | 515-1035 | $$$ |

| Brass | C260, C268 | Machinable, corrosion-resistant | 930°C | 50-100 | 200-500 | $$$ |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | High strength-to-weight ratio, corrosion-resistant | 1668°C | 150-400 | 240-1100 | $$$$ |

| Magnesium | AZ31, AZ61 | Lightweight, excellent strength-to-weight ratio | 650°C | 30-100 | 150-300 | $$ |

Protolis experts specialize in fabricating sheet metal components from these diverse materials, leveraging their unique properties to meet the specific needs of our clients.

How to choose the right materials for sheet metal fabrication?

Selecting the appropriate material for sheet metal fabrication ensures the final product’s performance, durability, and cost-effectiveness. Several factors must be considered to make an informed decision.

Ductility

Figure 15: Ductility of materials used in sheet metal fabrication

Ductility refers to a material’s ability to deform under tensile stress without breaking. High ductility is essential for bending, rolling, and stamping, where the material undergoes significant deformation.

- Stainless steel alloys such as 304 and 316 are known for their excellent ductility, making them ideal for applications requiring complex shapes and intricate designs.

- Copper alloys, including C110 and C101, also offer good ductility and are suitable for forming and bending electrical components and decorative items.

Tensile strength

Figure 16: Comparing tensile strength of materials used for sheet metal fabrication

The strength of the material is a critical factor, especially in applications where the component must withstand significant loads or stresses. Tensile strength and hardness are key indicators of a material’s strength.

- Titanium alloys, such as Grade 5 (Ti-6Al-4V), offer exceptional strength and are used in aerospace and medical applications where high performance is essential.

- Stainless steel alloys like 304 and 316 provide a high strength-to-weight ratio, making them suitable for structural applications and environments requiring robust materials.

- For general applications, steel alloys like A36 and A572 provide a good balance of strength and affordability.

Corrosion resistance

Corrosion resistance is vital for components exposed to harsh environments, moisture, or chemicals. Materials with high corrosion resistance ensure longevity and reduced maintenance costs.

- Stainless steel, particularly alloys 304 and 316, is renowned for its corrosion resistance, making it ideal for marine, medical, and food processing applications.

- Aluminum alloys, such as 5052, also offer good resistance to corrosion, suitable for outdoor and marine environments.

- Brass alloys like C260 and C268 are preferred for decorative applications and plumbing due to their resistance to tarnish and corrosion.

Environmental impact

Considering the environmental impact of material selection is increasingly important. Sustainable materials and processes can reduce the ecological footprint of fabrication projects. Aluminum and steel are highly recyclable, making them environmentally friendly choices. Using recycled metals reduces energy consumption and greenhouse gas emissions compared to processing raw materials.

Additionally, choosing processes that minimize waste and optimize material usage, such as laser cutting and precision forming, contribute to sustainability. Magnesium alloys, such as AZ31, offer a lightweight alternative with lower environmental impact due to their abundance and recyclability.

Budget and costing

Budget constraints and cost considerations play a significant role in material selection. The cost of materials, tooling, and processing must align with the project’s financial limits.

- Steel is often the most cost-effective option for large-scale projects due to its low material cost and availability.

- Aluminum provides a balance of cost and performance, suitable for mid-range budgets.

- High-performance materials like titanium and stainless steel are more expensive but necessary for specific applications requiring superior properties.

- Brass and copper, while more costly, are chosen for their aesthetic and conductive properties in specialized applications.

Choosing the suitable material for metal fabrication involves evaluating all of the above factors in detail. By considering these factors, manufacturers can ensure quality in their projects.

Surface finishing options for sheet metal fabricated parts

Surface finishing enhances sheet metal fabricated parts’ durability, appearance, and functionality. Various finishing techniques protect against corrosion, improve abrasion resistance, and add aesthetic value.

As machined finish

Figure 17: As finished or standard finish

“As machined” refers to the natural state of the sheet metal after fabrication without additional surface treatments. This option is cost-effective and suitable for parts where aesthetic appeal is not critical. The surface retains the metal’s appearance, including marks from machining and forming processes. However, it offers minimal protection against corrosion and abrasion. Metals like aluminum and stainless steel are often used “as finished” due to their inherent corrosion resistance. This finish is suitable for internal components or parts that will undergo further processing, such as painting or surface coating, later on.

Powder coating

Figure 19: Powder coating process

Powder coating offers a robust finish with excellent abrasion resistance. The surface must be pre-treated to ensure proper adhesion and corrosion resistance. This process involves applying a powder material and curing it under heat to form a hard, protective layer.

Coating thickness ranges from 70 to 150 μm, thicker than traditional paint. Powder coating is available in various colors and textures, enhancing the visual appeal of the parts. However, chips or incomplete coverage can lead to corrosion.

Passivation

Figure 21: Steel passivation process

It creates a thin, transparent oxide layer on the metal surface, offering good corrosion resistance. This process removes free iron from the surface, enhancing its protective qualities. Passivation does not change the durability or abrasion resistance of the metal. It makes it suitable for steel parts that require additional corrosion protection without altering their physical properties.

Zinc plating

Figure 22: Zinc plating process

It involves applying a zinc coating that serves as a physical barrier and sacrificial anode, protecting the underlying metal from corrosion. The coating thickness varies from 5 to 25 μm. This method is ideal for parts with detailed surfaces but not suitable for heavy-duty applications.

Zinc plating provides strong abrasion resistance and can sustain minor damage while remaining corrosion-resistant. It is often used as an undercoat for other finishes, though poor adhesion may occur.

Galvanized dipping

Figure 23: Hot dip galvanizing process

Galvanized dipping provides a thick zinc coating, acting as a sacrificial anode and barrier against corrosion. The coating can be adjusted in thickness, with thicker layers offering more protection but prone to flaking above 254 μm.

This finish is ideal for harsh environments due to its durability and good abrasion resistance. While galvanized dipping offers excellent longevity, surface damage can lead to corrosion.

Anodizing

Figure 24: Sheet metal anodizing

Anodizing enhances corrosion resistance and provides a hard, wear-resistant finish. This process is common in marine environments due to its excellent resistance to saltwater. The coating thickness ranges from 0.5 to 150 μm, making it suitable for parts that frequently contact other materials. Anodizing not only protects the metal but also improves its aesthetic qualities, with options for various colors. Anodizing is a process that is mainly applied to aluminum.

Each surface finishing option provides unique benefits, enhancing the performance and appearance of sheet metal fabricated parts. Choosing the right finish depends on the specific application requirements, environmental conditions, and desired aesthetic outcomes.

Surface finishing standards for sheet metal fabrication

Surface finishing classes for sheet metal fabrication determine the parts’ quality, cost, and application suitability.

There are three main classes: Class A, Class B, and Class C.

Class A

It is a cosmetic finish, free of surface imperfections or press brake marks. It is typically used for external-facing parts such as medical devices and food-grade products. This finish requires thorough polishing and is the most expensive option. It provides a smooth, high-quality appearance, ideal for parts that need to look aesthetically pleasing and flawless.

Class B

Its standard finish allows some surface imperfections, including press brake marks. It is commonly used for parts that will be plated or painted. This class is subdivided into:

- B-1: Standard finish with a light grain linear finish, achieved with a Timesaver.

- B-2: Dual action (DA) or orbital sand finish with all sharp edges removed.

- B-3: Tumble finish achieved using a vibratory tumbler for small parts.

Class B finishes are more economical than Class A, suitable for functional but not necessarily visible parts.

Class C

Class C is the default finish at most sheet metal shops. It is the primary finish, smooth enough to handle without cutting but with visible surface imperfections and press brake marks. It is often used for parts that will be further treated with paint or powder coating, as these treatments can cover the imperfections. This finish is the least expensive and suitable for internal components or non-cosmetic applications.

Understanding these classes helps select the finish based on the end-use requirements and budget.

What are the applications of sheet metal fabrication?

Figure 25: Sheet metal fabricated parts

Sheet metal fabrication is essential in numerous industries due to its versatility, precision, and durability. Below are some significant applications and the specific parts fabricated for each sector.

Automotive

The automotive industry extensively uses sheet metal fabrication for various components. Fabricated parts include body panels, chassis, exhaust systems, and brackets. These parts require high precision and durability to ensure safety and performance.

Materials like aluminum and high-strength steel are commonly used for their lightweight and robust properties. Advanced fabrication techniques like stamping, laser cutting, and welding are employed to produce complex shapes and structures efficiently.

Aerospace

In aerospace, sheet metal fabrication is critical for manufacturing lightweight yet strong components. Parts such as fuselage panels, wing structures, engine components, and brackets are fabricated from high-performance materials like titanium and aluminum alloys.

The stringent quality and precision standards in aerospace demand advanced techniques such as CNC machining, hydroforming, and chemical milling. These methods ensure the production of parts that meet the rigorous demands of aerospace applications, including high strength-to-weight ratios and resistance to extreme conditions.

Construction

The construction industry utilizes sheet metal fabrication for structural and architectural elements. Commonly fabricated parts include HVAC ducts, roofing, gutters, wall panels, and structural beams. Materials like galvanized steel, aluminum, and stainless steel are preferred for their corrosion resistance and strength.

Fabrication processes such as roll forming, welding, and plasma cutting produce durable and weather-resistant components. Sheet metal’s versatility allows for custom designs and intricate details, which are essential for modern architectural projects.

Electronics

Sheet metal fabrication is vital in the electronics industry for creating enclosures, chassis, brackets, and heat sinks. These parts require high precision and excellent conductivity and are often made from materials like aluminum and copper.

Techniques such as punching, bending, and anodizing fabricate parts that provide effective shielding, heat dissipation, and structural support for electronic devices. Producing intricate and customized designs is crucial in this industry to accommodate various electronic components and assemblies.

Medical

The medical industry relies on sheet metal fabrication to produce equipment and components that meet strict hygiene and safety standards. Fabricated parts include surgical instruments, medical device enclosures, hospital bed frames, and diagnostic equipment casings.

Stainless steel and titanium are commonly used for their biocompatibility, corrosion resistance, and ease of sterilization. Precision techniques like laser cutting, TIG welding, and passivation ensure the production of high-quality, safe, and reliable medical components.

Industrial

Sheet metal fabrication is essential for manufacturing industrial machinery and equipment. Machine frames, enclosures, panels, and brackets are fabricated to withstand heavy-duty use and harsh environments. Materials like mild steel, stainless steel, and aluminum are used for durability and machinability.

Metal fabrication processes such as bending, welding, and powder coating produce robust, long-lasting components. Customization and precision are key to ensuring that the fabricated parts meet the specific requirements of industrial applications.

At Protolis, we offer sheet metal fabrication services to all the above-mentioned industries. We specialize in creating custom parts tailored to your needs, ensuring high quality, precision, and reliability in every project.

Best design pratices for sheet metal

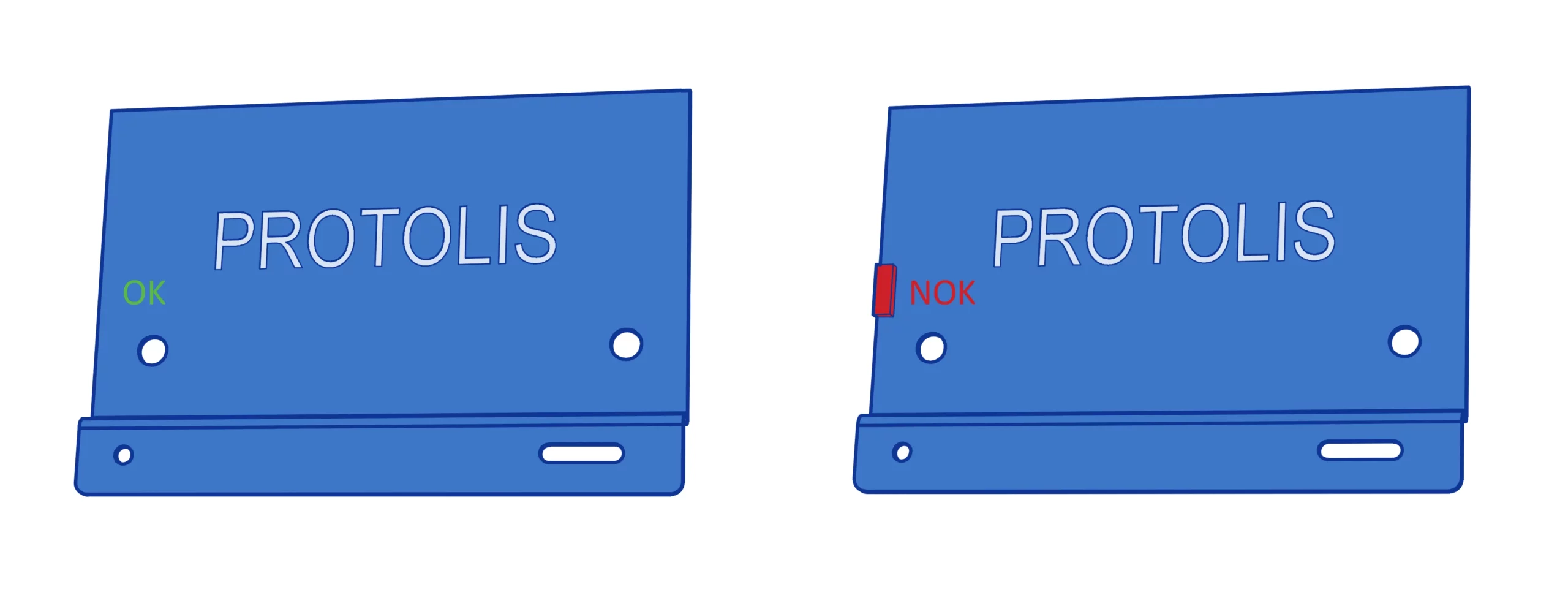

Understanding and applying best design practices is crucial for effective sheet metal fabrication. Here, we will discuss the best design practices to smoothly perform cutting, bending, and assembly operations.

Uniform wall thickness

The key factor for sheet metal parts is ensuring consistency in wall thickness. If certain features require variations in thickness, using welding or riveting processes may be a more cost-effective solution for areas with increased thickness.

Following the bending process of sheet metal parts, stress tends to concentrate in the corner areas, increasing the risk of cracks or fractures.

It is recommended that the inner bend radius be equal to or larger than the sheet metal thickness, with the outer radius naturally transitioning based on the optimized inner radius plus the material thickness.

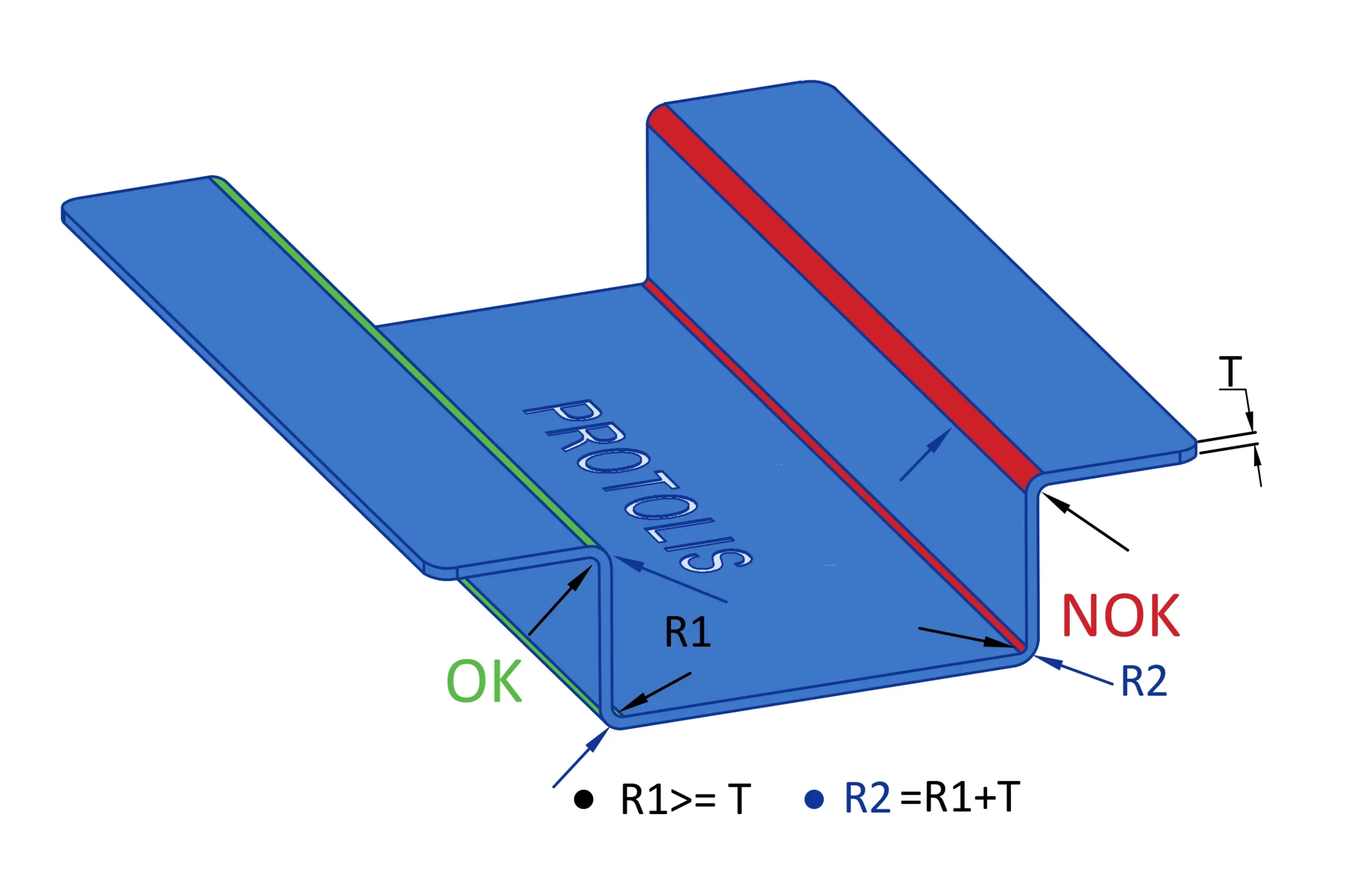

Bend Radius

Following the bending process of sheet metal parts, stress tends to concentrate in the corner areas, increasing the risk of cracks or fractures.

It is recommended that the inner bend radius be equal to or larger than the sheet metal thickness, with the outer radius naturally transitioning based on the optimized inner radius plus the material thickness.

Holes and slots

To avoid the risk of bulging, deformation, cracks, or fractures at round holes or slot holes near the bend of a sheet metal part, the distance between the holes and the bend must be greater than or equal to at least twice the sheet metal thickness.

Hems and curls

To reinforce sheet metal edges and prevent weak or sharp edges, the edges of sheet metal parts can be designed using a hemming process.

The inner radius of the hem must be at least equal to the material thickness, and the flat edge dimension must be at least four times the material thickness.

Notches and tabs

Notches and tabs are among the most commonly used features in precision sheet metal parts, and for good reason. They provide the necessary space for tools to access specific areas and help prevent spatial conflicts between parts or features, particularly during assembly. Slots are also integral to sheet metal design, offering both functional and aesthetic benefits. When appropriately placed, they can enhance ventilation or add decorative elements to the part.

To ensure functional and structurally sound notches, follow these simple design rules:

- The width of a notch should be at least 1 mm (0.040 in.) or equal to the material thickness, whichever is greater.

- The depth of a notch should typically not exceed 5 times its width, depending on its purpose. For standalone notches, the depth limitation does not apply.

For robust tabs, adhere to these fundamental principles:

- Tabs should be at least twice the material thickness or 3.2 mm (0.125 in.) wide, whichever is greater.

- The maximum tab length should not exceed 5 times its width. Exceeding this ratio can compromise strength, leading to undesired flexibility and deformation.

While exceptions may exist, following these basic guidelines will help ensure your tabs and notches are both functional and structurally sound.

Countersinks

If the sheet metal thickness exceeds around 3mm (0.118 inch) and includes flat-head screw fastenings, a conical recess can be added through CNC post-processing to secure the screws and prevent the head from protruding.

For sheet metal thicknesses less than 3mm, incorporating a conical recess is not recommended to avoid sharp edges and compromised strength.

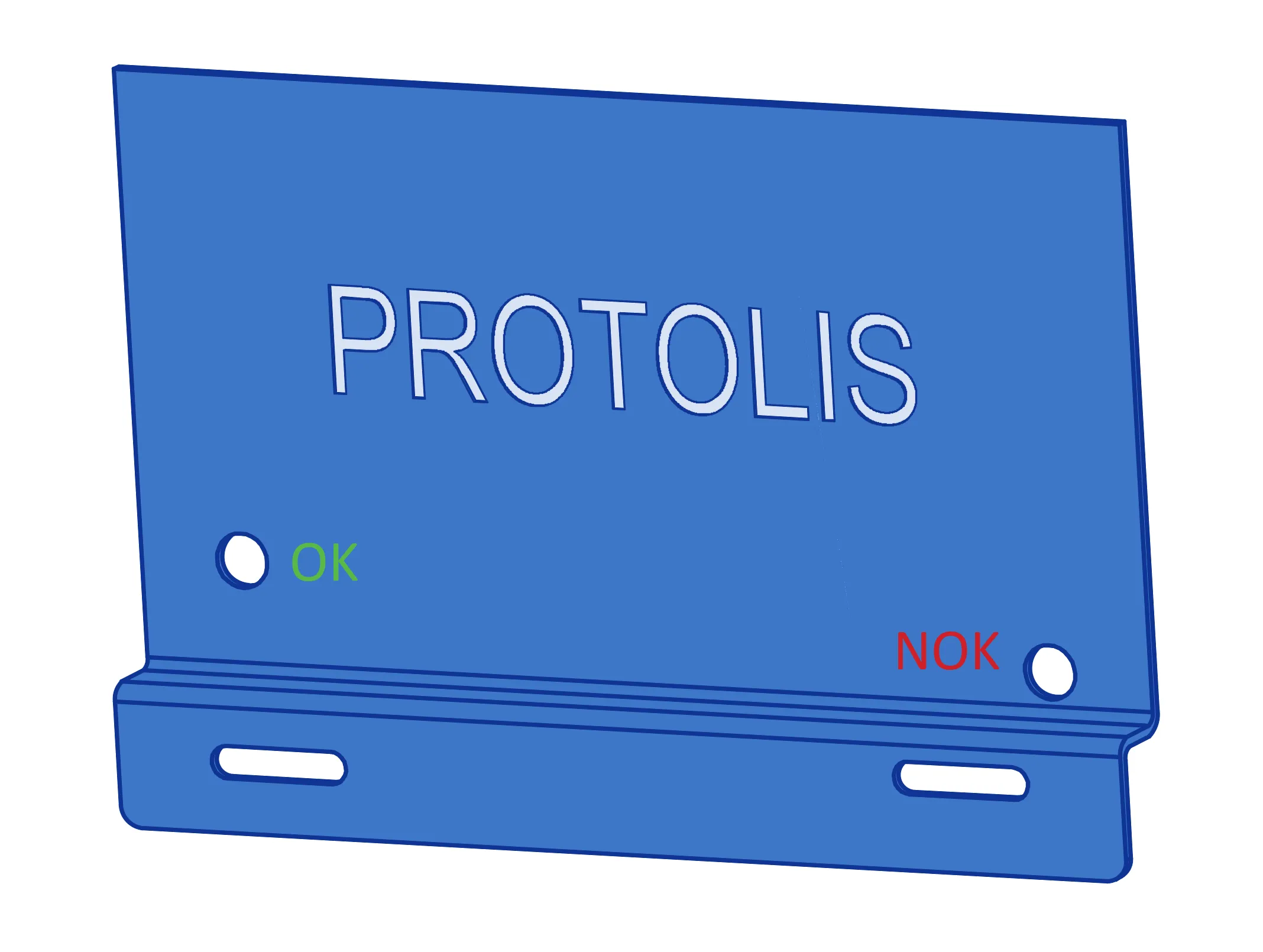

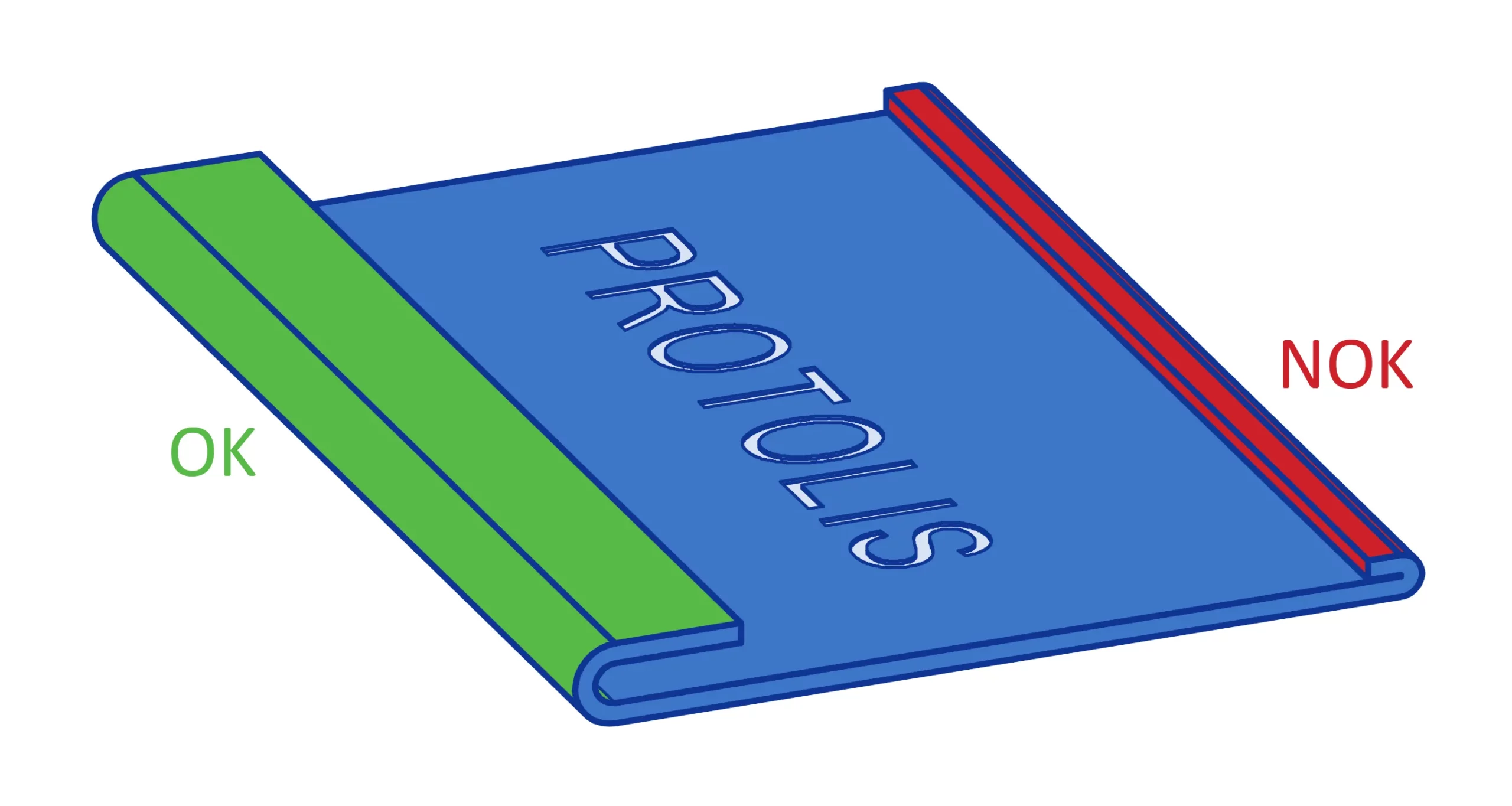

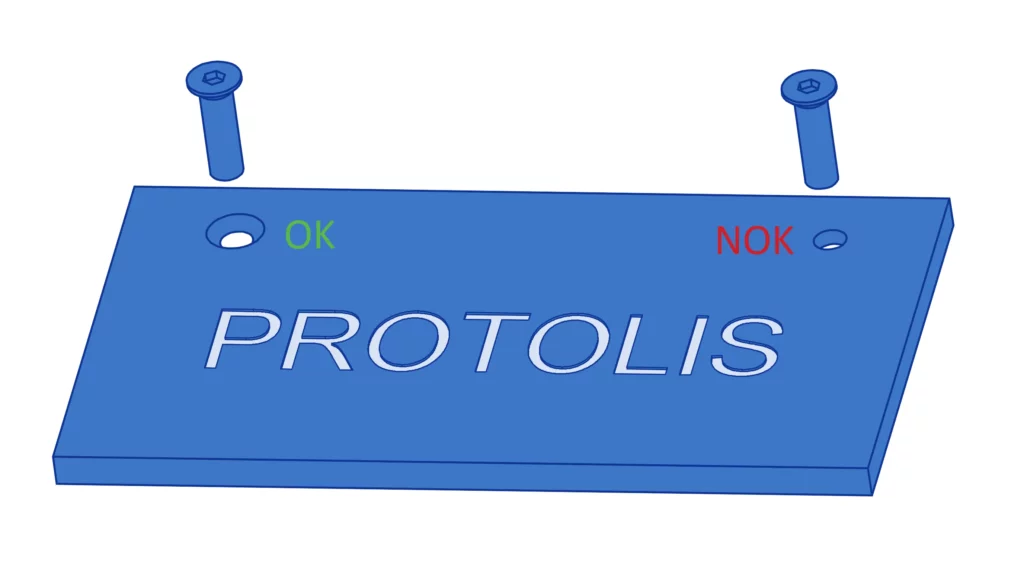

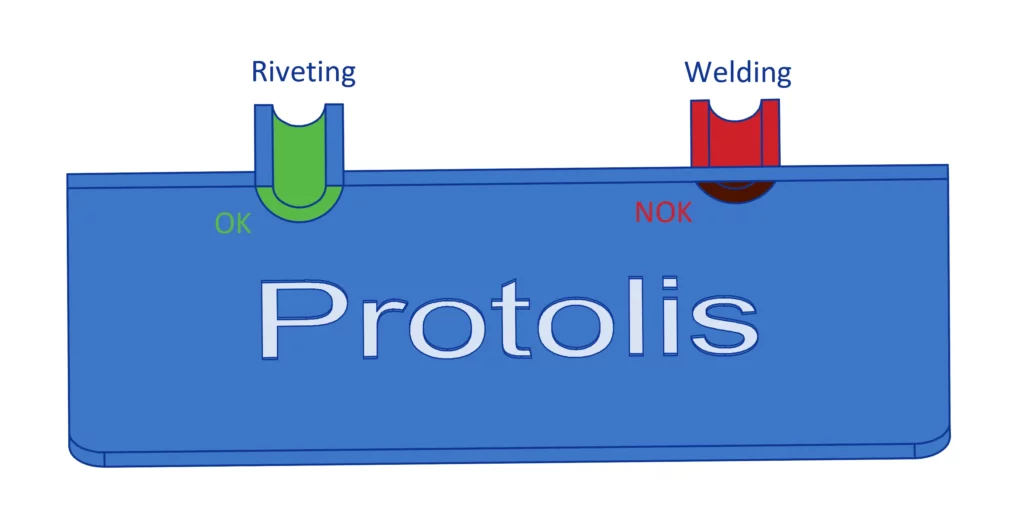

Riveting and welding

If the sheet metal thickness is around or less than 3mm (0.118 inch) and includes inserts or threaded fasteners, it is advisable to choose a riveted insert structure instead of welding. Welding thin-walled sheet metal can lead to deformation and make it challenging to maintain dimensional precision.

Cost optimisations for sheet metal

Sheet metal forming, like any other manufacturing process, has various factors that influence the final cost of parts and projects. This section explores these factors and offers proven ways to reduce the cost of sheet metal manufactured designs.

Six ways to reduce the cost of sheet metal fabrication

Reducing sheet metal fabrication costs is essential for enhancing profitability and staying competitive. Cost-cutting measures can lead to significant savings, enabling companies to allocate resources more efficiently and invest in other critical areas.

Here are the top six ways to reduce sheet metal fabrication costs.

1. Standard features design

Incorporating punch-form features like lances, embossments, and ribs with standardized sizes can significantly reduce costs. Standard sizes prevent manufacturing delays and eliminate the need for custom tooling.

Including precise dimensions in your RFQ ensures clear communication with manufacturers, further streamlining the process.

2. Optimize material usage

Efficient material usage is key to reducing costs. Nesting software can maximize the number of parts from each sheet, minimizing waste. Select readily available and less expensive materials and consider material thickness; thinner sheets often cost less but still meet structural requirements.

3. Standardize components

Standardizing components reduces costs by enabling bulk purchasing and minimizing the need for custom parts. Use standard sizes for holes, threads, and other features. This approach streamlines production and reduces setup times, leading to faster turnaround and lower costs.

4. Optimal bend radius

Designing parts with an optimal bend radius is crucial for cost efficiency. Internal bend radii and material thickness should be between 0.76 mm (0.030 in.). Most manufacturers have tooling for these specifications, allowing for quicker and cheaper production. Avoiding specialized toolsets or alternative methods for forming precise geometries can save time and money.

5. Simplify folds

Complex part designs increase fabrication costs. Simplify your designs by incorporating simple angled bends with a radius equal to or greater than the sheet’s thickness. Small bends on large, thick parts often result in inaccuracies, leading to higher costs. By focusing on simpler designs, you can maintain accuracy and reduce expenses. Refer to design guides on sheet metal for best practices to achieve cost-effective designs.

6. Limit the use of tight tolerance

Only critical surfaces of a part need tight tolerances. Excessive tolerance callouts for features like radii, hole diameters, and distances increase manufacturing costs. Assign tolerances only to mission-critical features to eliminate unnecessary expenses. By doing so, you ensure that resources are allocated efficiently, focusing on the most crucial aspects of the part’s functionality.

Reducing sheet metal fabrication costs requires strategic design choices. By adopting the above-mentioned practices, manufacturers can achieve significant cost savings. Propolis is dedicated to helping you save on sheet metal fabrication costs. With our advanced manufacturing techniques and commitment to quality, we ensure that your projects are completed efficiently and cost-effectively.

Conclusion

In summary, sheet metal fabrication is a versatile and efficient process that transforms raw metal sheets into functional parts and products. By utilizing techniques like cutting, forming, and assembly, manufacturers can produce durable components for various industries, including automotive, aerospace, and construction. The process supports small-scale prototypes and large-volume production runs, offering high precision and cost-effectiveness. Adhering to best design practices and selecting appropriate materials further enhances the quality and performance of fabricated parts.

At Protolis, we excel in providing top-notch sheet metal fabrication services. Our advanced machinery and skilled team ensure every project’s precision, efficiency, and reliability. Whether you need custom prototypes or high-volume production, we deliver exceptional quality tailored to your needs.

Ready to start your next project? Contact us today to discuss your needs and discover how we can bring your ideas to life with precision and excellence.