Manufacturing Guides

Explore comprehensive guides on technologies and learn how to design better parts using our manufacturing expertise.

CNC Machining Guide

We’ll explore the historical journey of CNC machining, its diverse uses, and the advantages it offers. We’ll also explore its limitations and offer insights into design considerations and cost factors.

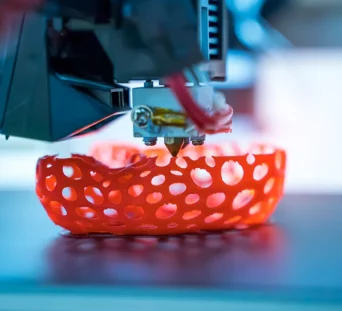

3D Printing Guide

3D printing, an innovative manufacturing process, enables the creation of complex, three-dimensional objects directly from digital blueprints. This guide explores the nuances of 3D printing, from its fundamental principles and types to materials used and best design practices.

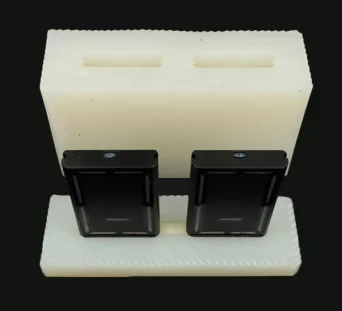

Vacuum Casting Guide

We will explore its foundational principles and historical evolution as well as its advantages, limitations, and material considerations. Additionally, we will offer insights on design best practices and cost considerations, equipping professionals with the knowledge to harness this technique’s full potential.

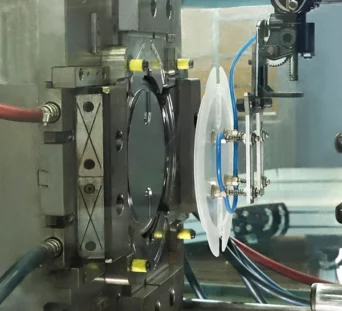

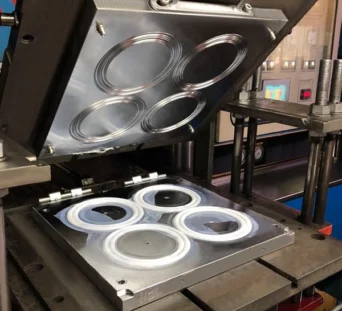

Plastic Injection Molding Guide

Welcome to our ultimate guide on injection molding. We will uncover the essentials of this manufacturing process, from its rich history to modern applications and design practices, offering straightforward insights into materials, design practices, cost considerations, and more.

Sheet Metal Forming Guide

Unlock the full potential of your manufacturing processes with our comprehensive guide to sheet metal fabrication. Dive into the details of transforming flat metal sheets into high-quality, functional parts and products. From cutting-edge techniques to best design practices, this guide is crafted to address the unique challenges faced by industry professionals. Whether you’re seeking to optimize efficiency, enhance precision, or reduce costs, our detailed insights will empower you to achieve unparalleled results.

Compression Molding Guide

As industries seek efficient and cost-effective manufacturing methods, compression molding for rubber stands out. This process delivers durable, high-quality rubber parts, combining design versatility with material compatibility.

Extrusion Guide

We will explore its foundational principles and historical evolution as well as its advantages, limitations, and material considerations. Additionally, we will offer insights on design best practices and cost considerations, equipping professionals with the knowledge to harness this technique’s full potential.