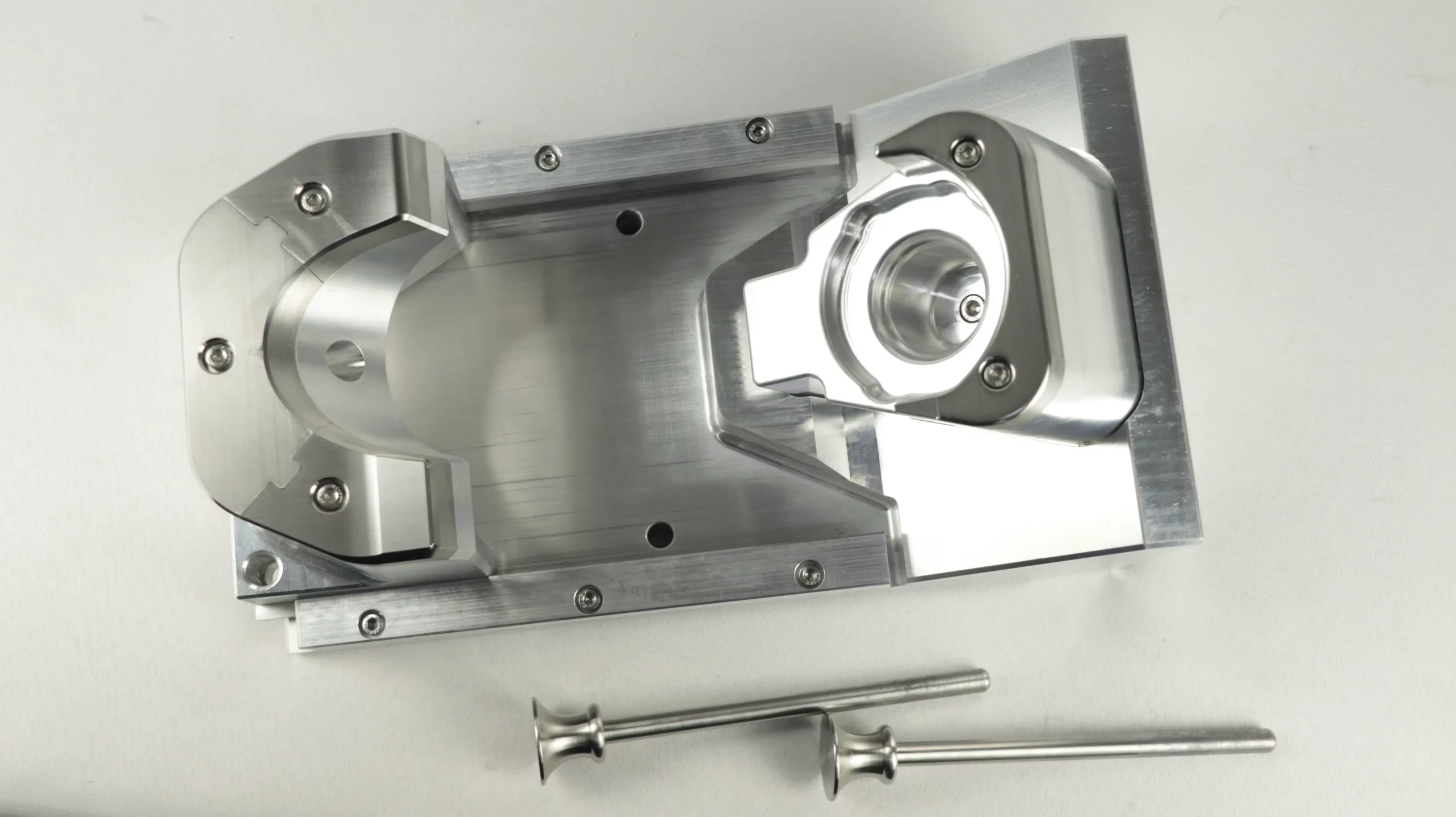

| Product | Jig for ultrasonic welding processes |

| Technology | CNC Metal machining |

| Material | Aluminium 6061 T6, Stainless steel 304 |

| Finish | Polished as machined |

| Timeline | 12 days |

| Quantity | 2 sets |

The objective of this project was to manufacture a positioning jig designed to enable welding between two plastic components. The task involved ensuring precise assembly, maintaining the functionality of holding the parts in place, and providing an aesthetically pleasing and safe design for the operator.

The technical challenges included complex machining and the adjustment of various components.

About our client

Our client is a company specializing in injection molding, with four sites and around a hundred injection presses. They operate in various sectors including automotive, construction, and more.

Technical challenges

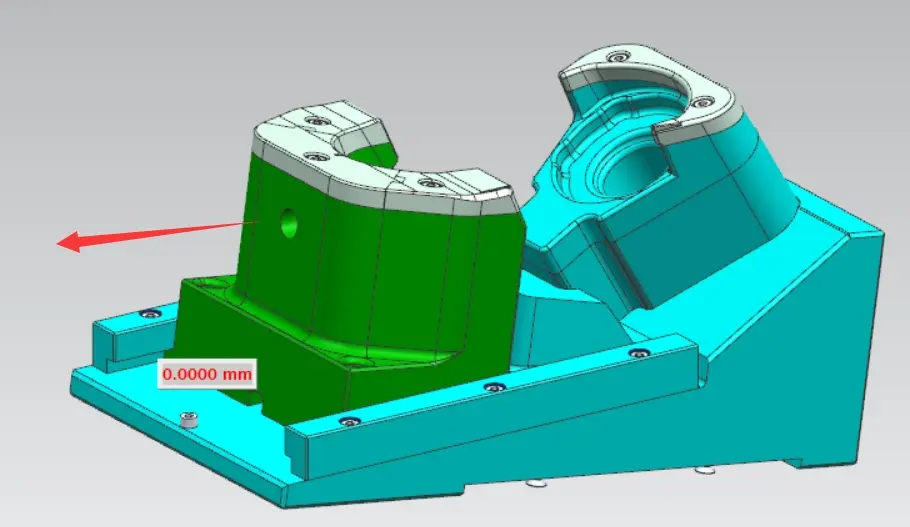

From a technical standpoint, designing jigs of this scale presents challenges. Precision machining is essential, as each component must be accurately positioned. Ensuring the proper fit with the plastic parts, while maintaining functionality, was crucial. The pins and screws had to be placed to guarantee functionality while preserving surface aesthetics. The structure is particularly complex, incorporating various elements such as screws, positioning pins, inserts, and other components.

Additionally, ergonomic considerations were taken into account to enhance ease of use without compromising the jig’s essential functions. The movement of the drawer had to perfectly align with the plastic parts, ensuring a smooth, unobstructed motion on the support. The ergonomic design of the rods on each side was developed not only to meet technical requirements but also to improve user comfort during operation.

Our solution

Throughout the project, our commitment to quality and precision ensured we met industrial requirements. Our mission was to create precise, functional, and ergonomic jigs, perfectly adjusted to the plastic parts, while guaranteeing ease of use.

This example demonstrates our ability to produce complete mechanical assemblies composed of multiple elements with precise tolerances and functions.