Rapid prototyping

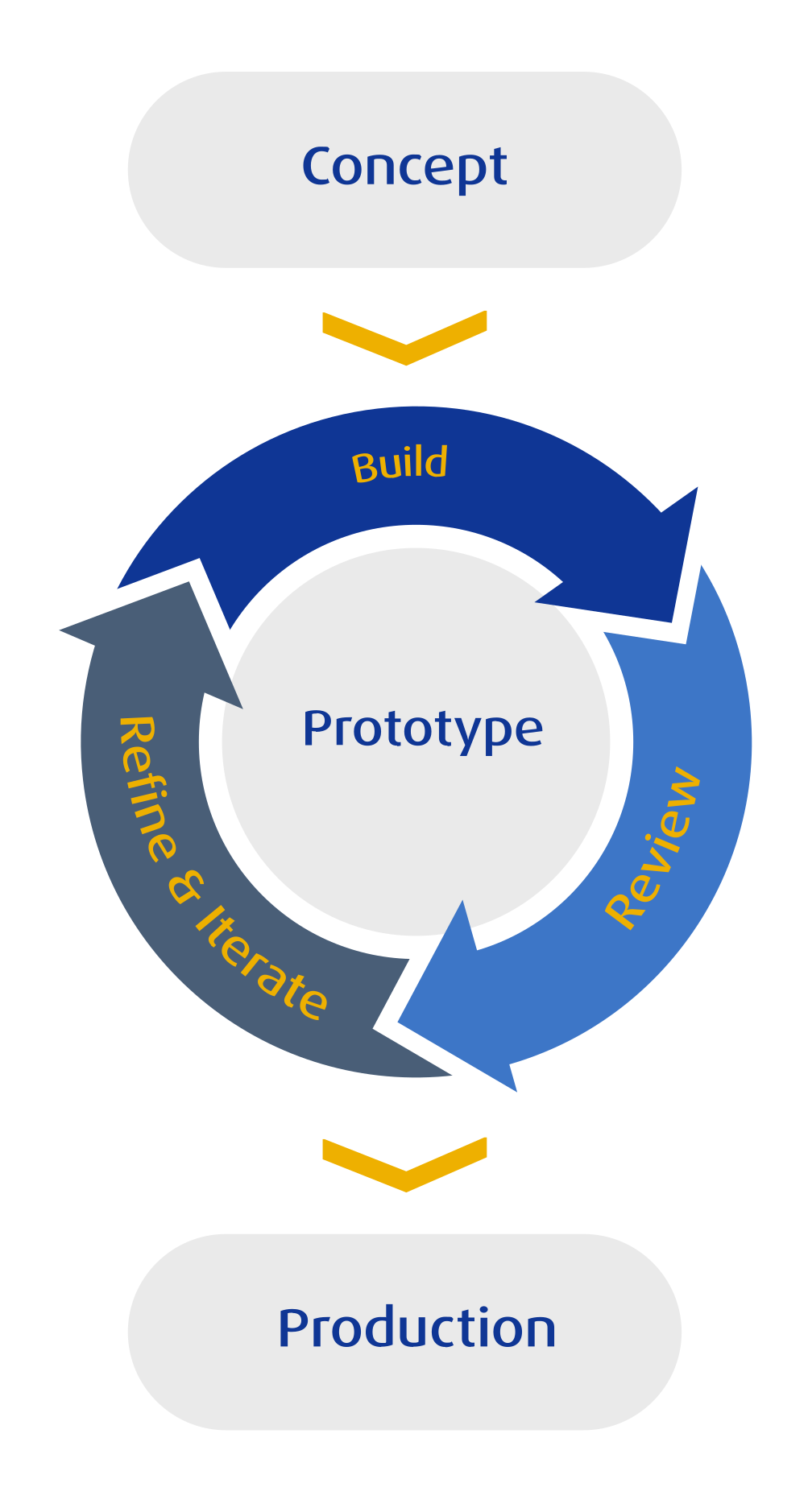

At Protolis, we take pride in our commitment to rapid prototyping, a discipline embedded in the very essence of our company and expertise. We turn your ideas into functional prototypes and support our clients in refining them before large-scale production.

What is rapid prototyping?

Prototyping or rapid prototyping involves swiftly creating physical components from CAD model data using diverse manufacturing techniques. The primary aim is to assess the design, test technology, analyze operational principles, and make improvements before moving on to mass production. Prototyping is crucial for certifications, regulatory testing, and ensuring compliance.

When is rapid prototyping used?

This essential step occurs in the process of developing a new product before investing in production tooling and launching into production.

In engineering, a prototype represents the first version of a product or part, as well as the various iterations until the final design is validated. Adjustments, informed by tests conducted on the prototypes, help improve the design, choice of materials, finishes, assembly and more.

When is rapid prototyping used?

Our prototype manufacturing technologies

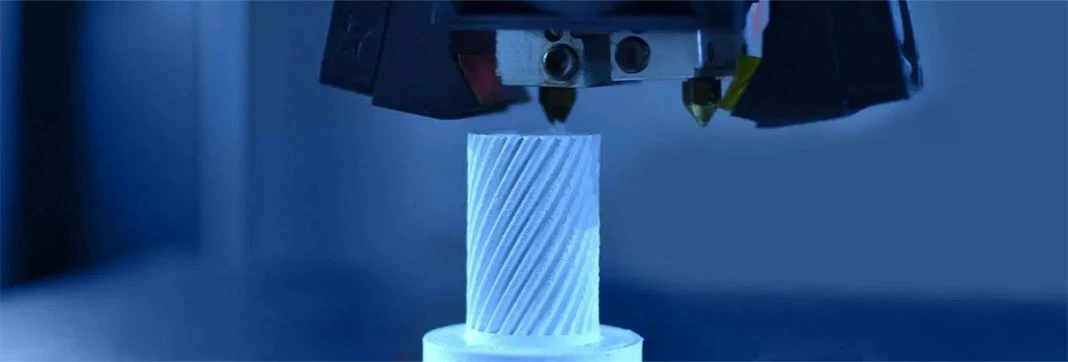

3D printing

3D printing is a direct and often cost-effective method to bring your parts to life, with SLS (selective laser sintering) being commonly used for plastics and SLM (selective laser melting) for metals.

Price:

Speed:

Design flexibility:

Manufacturability*:

Vacuum casting

Vacuum casting is the optimal solution for creating plastic prototypes with excellent functional and mechanical properties, along with a high-quality surface appearance. This process involves using a silicone mold to replicate parts.

Price:

Speed:

Design flexibility:

Manufacturability*:

CNC machining

CNC machining stands out as the most widely employed technology for rapidly manufacturing both plastic and metal prototypes, offering exceptional repeatability, accuracy, and precision.

Price:

Speed:

Design flexibility:

Manufacturability*:

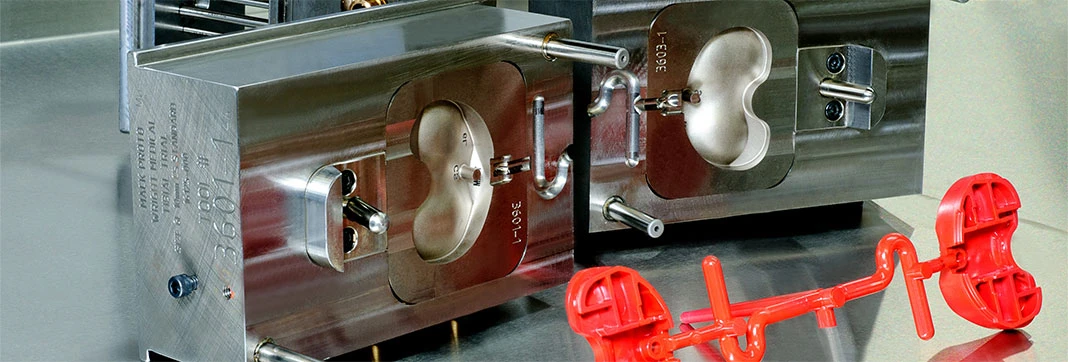

Rapid injection molding

We use prototype molds for rapid injection molding. These streamlined versions of production tools ensure series-like quality with the shortest possible turnaround time, delivering cost-effective plastic parts.

Price:

Speed:

Design flexibility:

Manufacturability*:

*Manufacturability : The “Manufacturability Index” for a prototype is a concept used in product development to assess how easily a particular design can be manufactured with high volume technology

Build your idea as you imagined it

Build your idea as you imagined it

That’s where we step in! As a rapid prototyping company we help you determine the best production methods, materials, and finishes to bring your idea to life. Assembly and fit testing can be performed in-house.

Streamline your development

Streamline your development

You may be looking for a quick and cost-effective solution to produce one or several parts, or an assembly composed of several elements. Take advantage of our expertise in prototyping to develop your project.

Our advantages

Design optimisation (DFM) and technical support

Design optimisation (DFM) and technical support 200+ of plastic and metal material available

200+ of plastic and metal material available 10+ finishes

10+ finishes Cost-effective

Cost-effective Quickturn around

Quickturn around

Our advantages

The benefit of rapid prototyping process

Prototyping is an indispensable part of the product development process. Its main benefit is to streamline your product journey from the concept to the market.

Testing and validation

Keep in mind what you want to evaluate by choose the right prototype type:

- Concept model: Also called a proof-of-concept prototype, his purpose to is to prove that the core concept or technology can work.

- Functional prototype: These are created to test and validate the functional aspects of a design such as how a product works, moves, and operates.

- Visual (look-alike) prototype: Focused on the appearance and aesthetics of the product, visual prototypes replicate the size, color, and surface textures of the final product but do not function.

Testing and validation

Reduce your development costs and timelines

Rapid prototyping allows you to create, test, and iterate prototypes within a few days, accelerating the validation process and minimizing costly errors.

This approach gives you a competitive advantage by enabling a faster time-to-market

Reduce your development costs and timelines

Learn about your manufacturability concept

Rapidly prototyping your concept allows you to gather valuable insights on production techniques, material selection, and cost considerations. This process ensures your concept is both innovative and manufacturing-ready.

Learn about your manufacturability concept

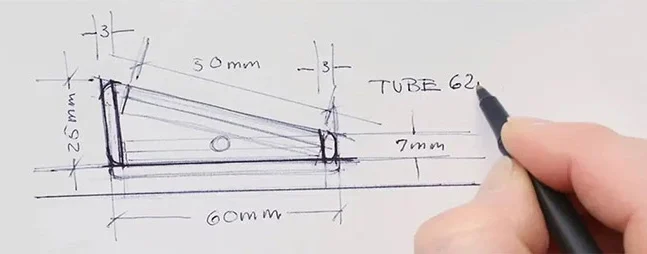

Examples of our prototyping work

Materials: Plastic

Reference: Heicast 8263

Technologies: Vacuum Casting

Industries: Building, Energy & Environment

Finishes: Fitting & assembly, Technical polishing

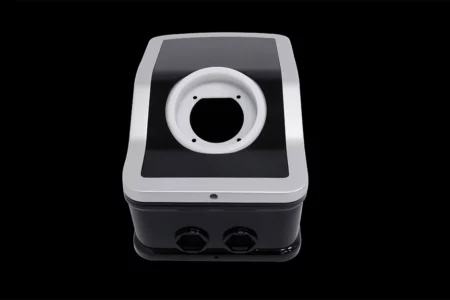

Materials: Plastic

Reference: Heicast 8263

Technologies: Vacuum Casting

Industries: Robotic & automation

Finishes: Technical polishing

Materials: Plastic

Reference: Heicast 8263

Technologies: Vacuum Casting

Industries: Consumer goods

Finishes: Fine or Cosmetic polishing, Fitting & assembly, Painting

Materials: Metal

Reference: 6061 T6

Technologies: CNC Machining

Industries: Industrial

Finishes: Technical polishing

Materials: Metal

Reference: 6061 T6

Technologies: CNC Machining

Industries: Automotive

Finishes: Technical polishing

Materials: Metal

Reference: 6061 T6

Technologies: CNC Machining

Industries: Agricultural

Finishes: Technical polishing

We are manufacturing committed

In today’s prototyping digital world, there’s a race to offer the quickest turnaround at the most competitive price. Unfortunately, this often means compromising on support and service. At Protolis, we’ve chosen a unique approach.

Committed to service

Customer projects remain at the center of our vision. We take time to work alongside our customers and provide support and advice at each stage of the project.

Committed to quality

Whether it’s for a single part or a sub-assembly composed of different materials and technologies, we control all components for a perfect fit and high-quality product.

Committed to success

Your satisfaction is our top priority. There’s nothing more motivating for us than hearing our customers are pleased with the parts they receive.

FAQ for rapid prototyping

What are the main applications in prototyping?

Prototyping is essential for a fast product development to refine and test concepts before full production. There are various types and applications depending on the industry.

Here are the key applications for our clients using our services:

1 – Product Design and Development:

- Concept Testing: Early-stage prototypes are used to explore and validate new ideas.

- User Testing and Feedback: Prototypes help gather user feedback to improve usability and functionality.

- Iterative Design: Prototypes allow for rapid iteration and refinement of design based on testing and feedback.

2 – Engineering and Manufacturing:

- Mechanical Testing: Physical prototypes are used to test the mechanical properties and performance of components.

- Fit and Assembly: Prototypes ensure that parts fit together correctly and identify any issues in the assembly process.

- Material Selection: Different materials can be tested in prototypes to determine the best option for the final product.

3 – Healthcare and Medical Devices:

- Device Testing: Prototypes of medical devices are used to test functionality and safety.

- Clinical Trials: Prototypes are used in clinical trials to gather data on efficacy and safety.

- Ergonomic Assessment: Ensures that medical devices are comfortable and easy to use for healthcare professionals and patients.

4 – Consumer Electronics:

- Functionality and Performance Testing: Prototypes are used to test electronic components and overall device performance.

- User Interaction: Helps in refining the user interface and interaction with the device.

- Aesthetic Evaluation: Ensures that the final product meets design and aesthetic standards.

5 – Automotive Industry:

- Design Validation: Prototypes are used to validate the design and functionality of automotive components and systems.

- Safety Testing: Prototypes undergo rigorous safety tests, including crash testing.

- Performance Evaluation: Assesses the performance of different components and systems in real-world conditions.

What is the right technology to use for prototyping?

The choice of technology for rapid prototyping depends first on the desired level of visual and mechanical fidelity of the prototype. Moreover, in our case, we always prioritize production methods with shorter lead times and lower costs for our clients.

Here are some of the most commonly used technologies for rapid prototyping, along with their typical applications:

– 3D Printing (Additive Manufacturing): Very frequently used and highly favored for complex geometries and rapid iterations.

– CNC Machining: Ideal for high-precision parts across materials like metals, plastics, and wood. Suitable for functional prototypes requiring durability and precise testing.

– Rapid Injection Molding: Enables small batch production of prototypes using production-grade materials. Ideal for functional and market testing of designs.

– Urethane Casting: Produces high-quality parts from silicone molds, suitable for small production runs and functional prototypes mimicking injection-molded parts.

What quantity are produced in prototyping?

The quantity of prototypes produced during the prototyping phase can vary widely depending on the project’s requirements, the development stage, and the specific goals of the prototyping effort.

Here are some typical scenarios and corresponding quantities:

– Conceptual Prototyping:

Quantity: Usually 1 to a few prototypes.

Purpose: To explore and validate initial ideas, concepts, and basic designs. These prototypes are often rough and used to gather early feedback.

– Functional Prototyping:

Quantity: A few to several prototypes.

Purpose: To test specific functionalities and ensure the design meets performance requirements. These prototypes are more refined and may undergo various iterations based on testing results.

– User Testing and Feedback:

Quantity: Several prototypes, possibly up to a dozen or more.

Purpose: To gather feedback from potential users and stakeholders. Multiple prototypes may be needed to accommodate different user groups or to test various design iterations simultaneously.

– Design Validation:

Quantity: Multiple prototypes, typically ranging from a few to a few dozen.

Purpose: To validate the final design before mass production. These prototypes are often highly detailed and close to the final product in terms of materials and construction.

– Engineering Validation and Testing (EVT):

Quantity: Dozens to hundreds of prototypes.

Purpose: To test the design’s performance, reliability, and manufacturability. This stage often includes extensive testing and refinement, with prototypes used for various engineering tests.

– Pre-production and Pilot Runs:

Quantity: Hundreds to a few thousand prototypes.

Purpose: To fine-tune the manufacturing process and identify any final adjustments needed before full-scale production. These prototypes are typically built using the same processes and materials as the final product.

– Regulatory and Certification Testing:

Quantity: Several to dozens of prototypes.

Purpose: To meet regulatory requirements and obtain necessary certifications. These prototypes are tested according to industry standards and regulatory guidelines.

– Market Testing and Early Adoption:

Quantity: A few hundred to a few thousand prototypes.

Purpose: To introduce the product to a limited market, gather feedback, and make any final adjustments. This stage helps validate market acceptance and identify any last-minute improvements.

What factors influence the cost of prototyping?

– Design Complexity: Intricacy and sophistication of the design affect labor and material costs.

– Materials Used: Choice of materials impacts both material cost and manufacturing processes.

– Prototyping Technology: Different technologies vary in setup, operational costs, and efficiency.

– Geographical Location: Costs can vary based on local labor rates and availability.

These are some of the most common factors, but there are numerous other considerations that can influence prototyping costs.

How long does rapid prototyping takes?

The factors influencing time are similar to those affecting cost (explained previously). Typical times per technology include:

– 3D Printing: Can range from a few hours to several days, depending on the size and complexity of the part.

– CNC Machining: Typically takes a few days to a couple of weeks, depending on precision and complexity.

– Injection Molding: Creating the mold can take several weeks, but once the mold is made, producing parts is quick.

– Laser Cutting and Engraving: Usually takes a few hours to a couple of days.

– Casting: Can take several days to weeks, depending on the complexity of the mold and part

These are general timeframes, and actual times may vary based on specific project requirements and production conditions.

Is 3D printing the best solution for prototyping?

3D printing is a highly versatile and popular solution for prototyping, but whether it is the “best” solution depends on various factors such as the specific requirements of the project, the materials needed, the desired fidelity of the prototype, and the stage of development.

3D printing is an excellent solution for many prototyping needs due to its speed, cost-effectiveness, and ability to produce complex designs. It is particularly well-suited for early-stage prototyping, iterative design processes, and low to medium volume production.

However, for projects requiring high precision, specific material properties, large-scale production, or very high-quality surface finishes, other prototyping methods such as CNC machining, injection molding, or urethane casting might be more appropriate.

Ultimately, the best solution for prototyping depends on the specific requirements and constraints of the project. In many cases, a combination of different prototyping methods may be used to leverage the advantages of each.