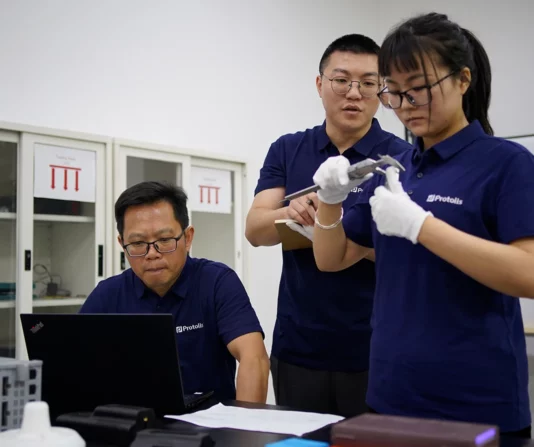

Quality control

At Protolis, our responsibility is to deliver your projects with the expected level of quality. Our quality team is dedicated to quality, and takes pride in adhering to best practices in every aspect of their work.

How we guarantee a quality experience

Our certifications

In addition to implementing quality best practices, our company is certified ISO 9001:2015 and ISO 13485. But that’s just the beginning.

Beyond certification, our quality engineering team continuously improves our production processes, management systems, and data transmissions to meet the highest standards.

Our certifications

Our metrology capabilities

Our fully equipped in-house metrology department has access to a range of conventional tools such as calipers, micrometers, and various gauges (height, pin, thread, etc.).

In addition to these tools, we also have a CMM (Coordinate Measuring Machine) and an optical comparator, which enhance our capability to provide precise and accurate measurement reports (tolerance up to 0.01 mm /0.0004 in).

Our metrology capabilities

Our production standards

We have established a comprehensive set of processes to ensure that the highest manufacturing standards are upheld for every custom part you order. These guidelines encompass dimension tolerance, finishes, material selection, and more.

For more detailed information, please refer to our production methods page.

Our production standards

We understand your exact needs

Like any manufacturer, we adhere to the technical documents you provide (3D and 2D drawings that specify tolerances and finishes). To take it a step further, let us know everything about your part’s environment and the expected function. As a committed manufacturer, we will always seek to gain a deeper insight to deliver accordingly.

How we guarantee quality parts

Our multi-step quality control process ensures that each part meets the necessary specifications, highlights any issues or concerns for discussion, and can be customized to incorporate various compliance requirements.

Incoming inspection

Once the material certificates become available, we will promptly provide them to you. Additionally, we have a X-ray material tester that allows us to identify various types of metals and plastics in just 30 seconds, ensuring the usage of the correct materials.

Production control

Regular inspections are conducted at various stages of production. Implementing strong quality control measures during production enables us to minimize rejections in later stages and reduce any negative impacts on lead time.

General inspection

Our general inspection protocol focuses on the main dimensions and their tolerances. Our quality control teams conduct a visual inspection of each part (color, finishes, etc.), provide a comprehensive report, and highlight any instances of non-conformity prior to shipping.

Quality documentation

We can tailor our processes to meet your specific quality document requirements. For example, we can provide a comprehensive dimensional inspection report, certificates such as REACH and RoHS compliance, or certificates of conformance as needed.

Our standards

Our expert team can provide guidance and support to ensure that your parts comply with a wide range of regulations and standards related to safety, performance, and suitability for various applications. These include, but are not limited to:

- Food grade compliance

- Flammability according to the UL 94 standard

- Resistance to high temperatures

- Resistance to UV radiation

Our standards

Our scope of services

Project Process

Finishes

Assembly-fitting

FAQs about quality control

What is the course of action if I receive incorrect parts?

In the event that you discover any instances of non-conformity with the received parts that were not previously documented in the QC report, we kindly request that you promptly inform us. We prioritize all quality claims and will initiate a comprehensive investigation without delay. Your project manager will engage in a discussion with you to ensure a clear understanding of the issue and subsequently develop an action plan, proposing suitable resolutions to address the matter effectively.

What quality control measures does Protolis implement?

We use advanced quality control techniques, including dimensional checks, material inspections, and functional tests to ensure that every part meets the required specifications.

How does Protolis ensure the accuracy and precision of parts?

Our production processes are calibrated for high precision, and we conduct regular checks using precise measurement tools to maintain accuracy.

Is there a quality assurance process before shipping?

Yes, all parts undergo a final quality assurance check, which includes a thorough inspection for any defects or deviations before they are shipped.