Sheet metal fabrication

At Protolis, we offer specialized services for producing precision sheet metal parts for prototyping and low-volume production purposes. Our specialized solution includes cutting, forming, and post-processing services, providing a complete service for custom sheet metal forming.

- 1 to 1000+ parts

- 10+ sheet metal types available

- Versatile manufacturing capabilities

- Ready in 3-5 days

- 8+ finishing options

What is sheet metal fabrication?

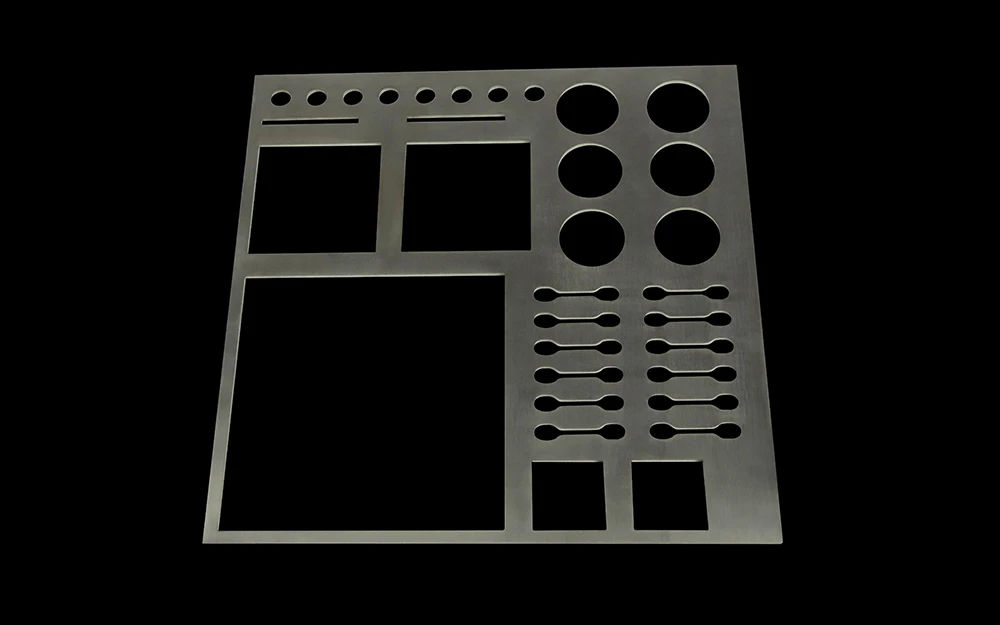

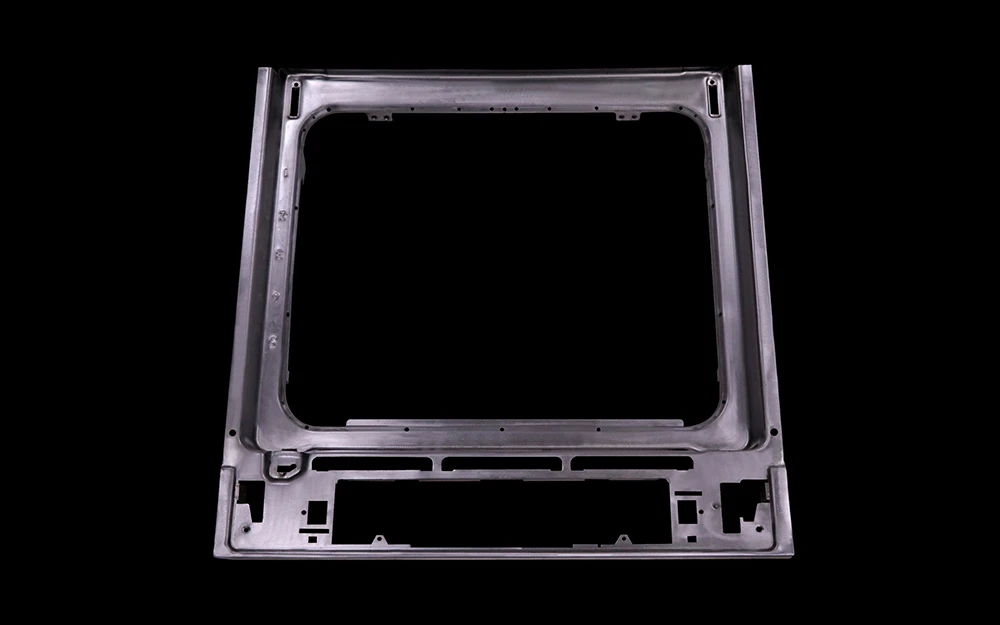

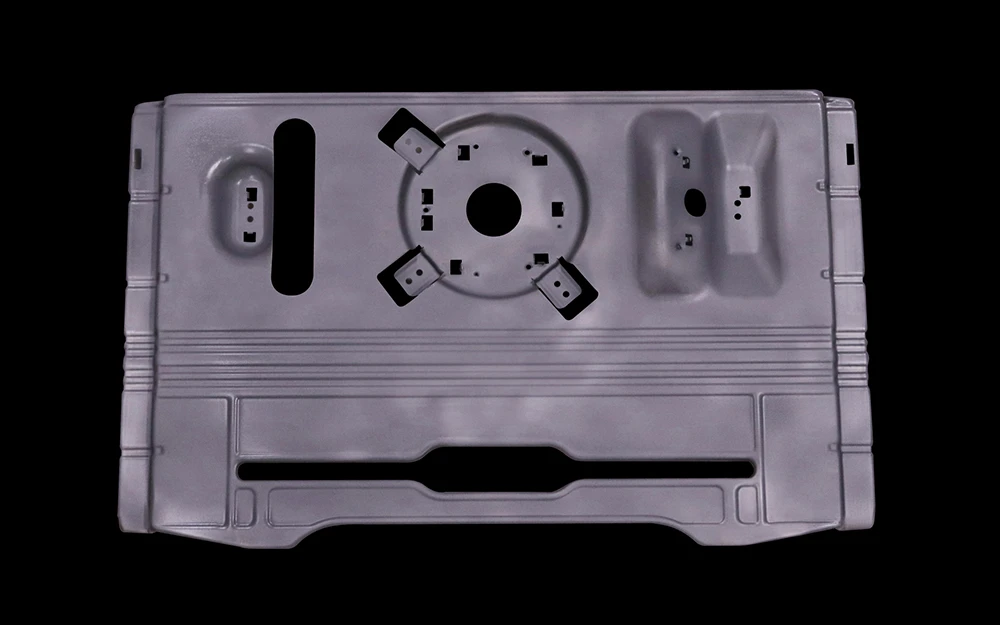

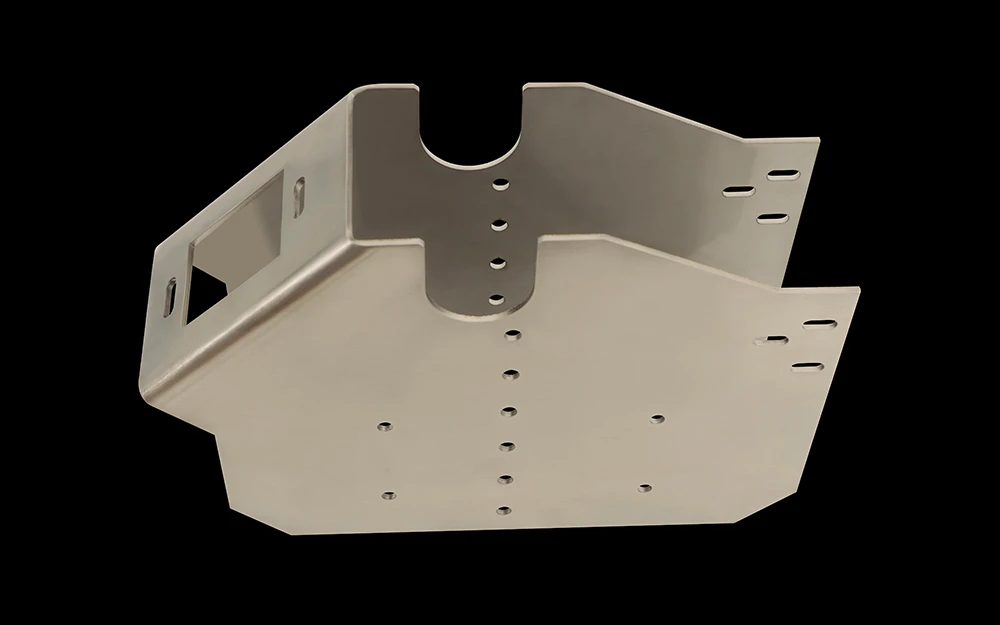

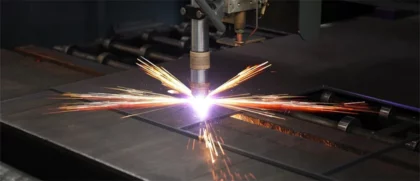

Industrial sheet metal work, particularly fine sheet metal work, is a metal manufacturing process that transforms a flat sheet of a few millimeters into a three-dimensional piece. The process begins with cutting of the metal, known as blanking, followed by shaping the sheet through stretching, punching, or bending to achieve the desired form.

Modern advancements like laser cutting and CNC machining have significantly improved the precision and efficiency of sheet metal processing. Additionally, its recyclability adds an environmentally friendly aspect to its broad range of uses.

What is sheet metal fabrication?

Sheet metal services

Protolis offers a variety of sheet metal prototyping processes to meet your specific needs. Our sheet metal capabilities complement other machining services, such as CNC machining, allowing us to meet a diverse range of manufacturing needs.

Cutting services

We offer laser cutting, waterjet cutting, and plasma cutting services. Laser cutting is used to create the internal holes and edge features of blanks.

Forming services

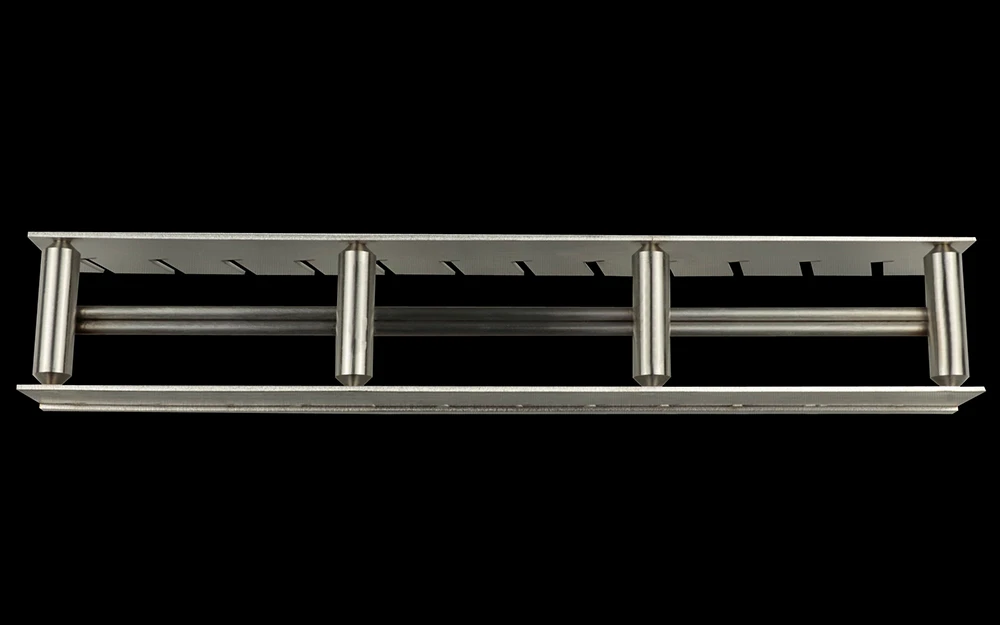

We offer bending, punching, and deep drawing to shape the metal with precision and accuracy. We can also develop custom die tools for complex forms.

Post-processing services

We provide post-processing services like welding and threading to enhance and assemble your sheet metal components.

Your project in 5 steps

Get your rapid sheet metal prototypes or production parts in no time. A flexible organization providing a personalized response to your need without any setback.

Your quote

Upload files and specifications

DFM

Design optimizations

Production

Close follow-up

Quality control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

Applications

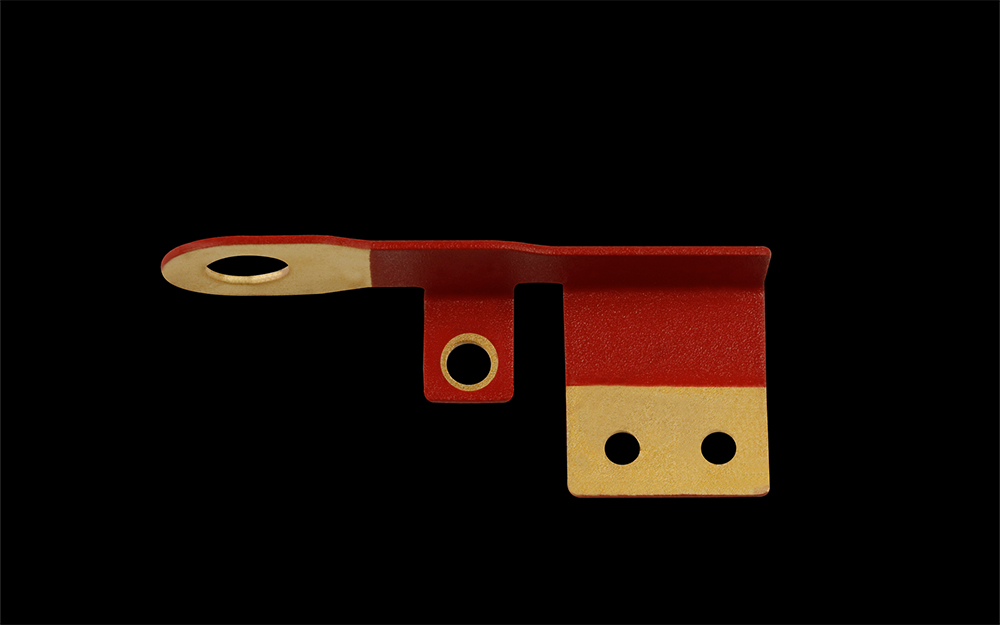

Sheet metal parts are used in many industries such as automotive (e.g. chassis), consumer appliances (e.g. kitchen equipment), aeronautics (e.g. fuselage), construction (e.g. brackets), and more, making them widely used in our everyday surroundings.

Sheet metal materials

We offer a wide range of metal materials such as aluminum, steel, stainless steel, brass, and copper, for customizing your prototype and low-volume production profiles using sheet metal. Below is a non-exhaustive list of commonly used materials for sheet metal fabrication.

General sheet metal production characteristics

Sheet metal finishes

Explore an extensive range of finishing choices that modify the surface of fabricated sheet metal parts, offering benefits such as increased corrosion resistance, improved aesthetic appeal, and reduced cleaning efforts.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

Powder coating is similar to liquid spray paint, except that this process uses a dry powder. It improves the resistance to wear and corrosion. The resulting surface is uniform.

This polishing generally involves changing the level of roughness of a surface by various manual, mechanical, or chemical techniques. This can change the dimensional or geometric accuracy of the part.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

Brushing is a surface finishing method that forms continuous paralleled lines on the surface of metal parts. The purpose is usually to obtain a decorative effect with a slight level of reflection.

Sand blasting is the high-pressure projection of silica sand on the surface of the workpiece to create a matte surface, including creating aesthetic consistency for plastic and metallic parts.

Sheet metal manufacturing capabilities

At Protolis, we have strong partnerships for metal sheet manufacturers. Our dedicated team ensures careful project management with a focus on quality and timely delivery. We handle post-processing operations like welding and assembling in-house.

Sheet metal FAQs

How long does it take to sheet metal prototype fabrication?

The lead time for sheet metal fabrication prototypes can vary based on multiple factors. These factors include the complexity of the design, material availability, and the need for additional surface treatments or post-processing operations. Generally, most prototype sheet metal fabricators can deliver parts within a few days to a few weeks, depending on the project’s scope and specific requirements.

Is there a minimum order quantity?

Protolis does not impose a minimum order requirement for the majority of its services. Whether you need just one item or more, feel free to place an order according to your exact needs. Additionally, our services are designed to support your scaling requirements, as you increase your order quantity, you may experience a significant reduction in the price per unit, and certain processes can become more cost-effective.

What are the benefits of working with a prototype sheet metal fabricator?

Collaborating with a prototype sheet metal fabricator such as Protolis offers several advantages. These include access to state-of-the-art manufacturing methods and equipment, the capacity to swiftly produce custom-designed parts, and efficient iterations on designs and prototypes.

Related resources

Extrusion Guide

Racing car bodywork for one of the world’s premier auto shows