Resins for vacuum casting

Resins used for vacuum urethane casting are typically polyurethanes designed to be equivalents to production thermoplastic materials. Protolis provides a wide range of grades, each tailored to offer distinct advantages and a wide range of properties to create high-quality castings.

- High quality: These materials are engineered to achieve high-quality and functional parts.

- 13+ resins ready for urethane casting material from well-known suppliers

- Colored: Most grades can be tinted.

- Transparent and rubber-like grades available

Common polyurethane vacuum casting grades

Discover the possibilities of materials for vacuum casting.

Description

This is a flame-retardant grade material with very good dimensional stability and well-balanced physical properties.

Applications

General applications similar to ABS with the advantage of being certified fire retardant UL94V-0.

Description

This is a resin material with well-balanced physical properties and dimensional stability. It has good resistance to most chemicals and meets Japanese food grade certification.

Applications

General applications similar to ABS plastic.

Description

A material with very good mechanical properties and temperature resistance, as well as good chemical resistance. Can be charged with an additional 20% of glass fiber.

Applications

General applications that require high temperature resistance (120°C).

Description

A grade of material with high elongation, good flexibility, and impact resistance. Can be charged with an additional 20% of glass fiber.

Applications

General applications similar to PP plastic.

Description

Transparent grade material with good physical properties, UV resistance and color pigmentation.

Applications

Most used for general application similar to PMMA plastic that require transparency and UV resistance.

Description

This grade material has good mechanical properties and is impact- and flextural-resistant. It also has clear aspect enabling, making it the best option for color pigmentation.

Applications

General applications similar to PMMA plastic that require color tinting with bright aspects and deep color.

Description

This is a rubber-grade material with very good rebound elasticity and flowability as well as good chemical resistance. It meets the standard for Japanese food grade certification.

Applications

General applications without color-tinted requirements.

Description

A transparent rubber-grade material offering better pigmentation properties but less elongation.

Applications

General applications with color-tinted requirements.

Description

A grade material with good mechanical properties, dimensional stability, and heat resistance.

Applications

General applications that require high temperature resistance (100°C).

Description

This grade material has good mechanical properties and high temperature resistance. It can be charged with an additional 20% of glass fiber.

Applications

General applications that require fiber.

Description

This is a resin with very high heat resistance, mechanical properties, and acid/oil resistance.

Applications

General applications similar to POM plastic.

Description

This grade features good thermal properties and can be easily colored with CP colorants. It also has UL-94 V0 and FAR 25 certification

Applications

General applications that require UL-94 V0 and FAR25 certification.

Vacuum casting services

Vacuum casting, or urethane casting, starts with a master pattern. A silicone mold is created around it, and resin is poured in, curing inside a vacuum chamber. This process allows for multiple part production from one mold, reducing costs through economies of scale.

At Protolis, we offer vacuum casting manufacturing service to produce your custom high-quality plastic parts for prototyping and low-volume production purposes.

Vacuum casting services

Our finishes for vacuum casting

Our range of vacuum-casted plastic parts comes with a variety of finishing options, such as painting, technical or cosmetic polishing, and chrome plating.

The pigmentation process makes it possible to produce pieces naturally colored in the mass of certain plastics. It is possible to choose the desired RAL or Pantone, with color pigments mixed with the material. This is applicable for rigid or flexible parts.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

There are several degrees of transparency depending on the technologies and materials used. The opacity can also be manually adjusted by polishing, sanding, or pigmentation.

We offer various methods to print or engrave your logo, texts, and symbols to give a finished appearance to your pieces.

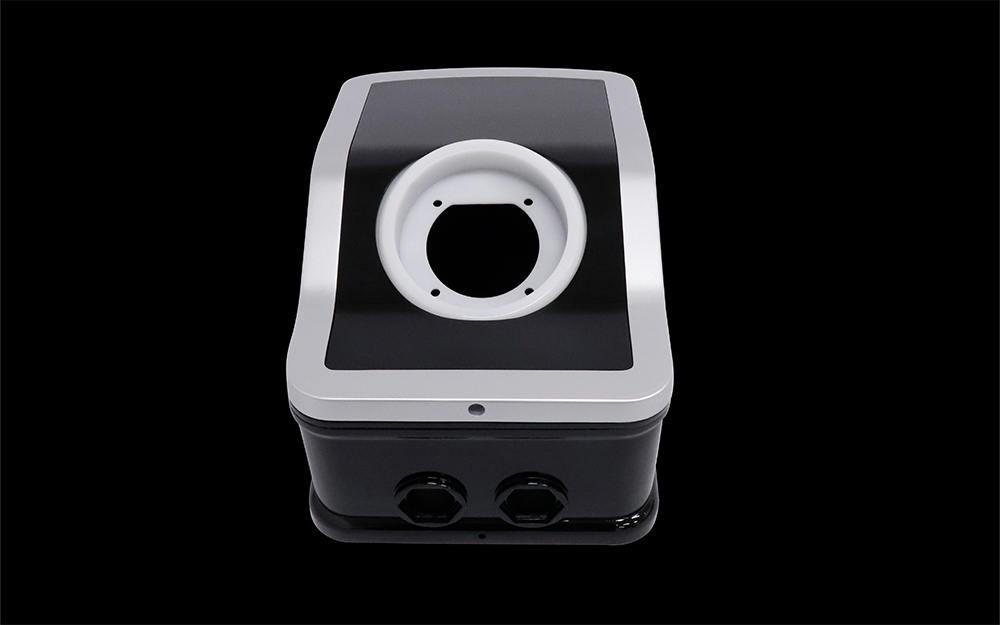

Chrome plating is a technique of applying a thin layer of chromium onto a substrate through galvanic or vacuum plating. This additional layer not only improves the aesthetic but prevents corrosion and wear.

Applications

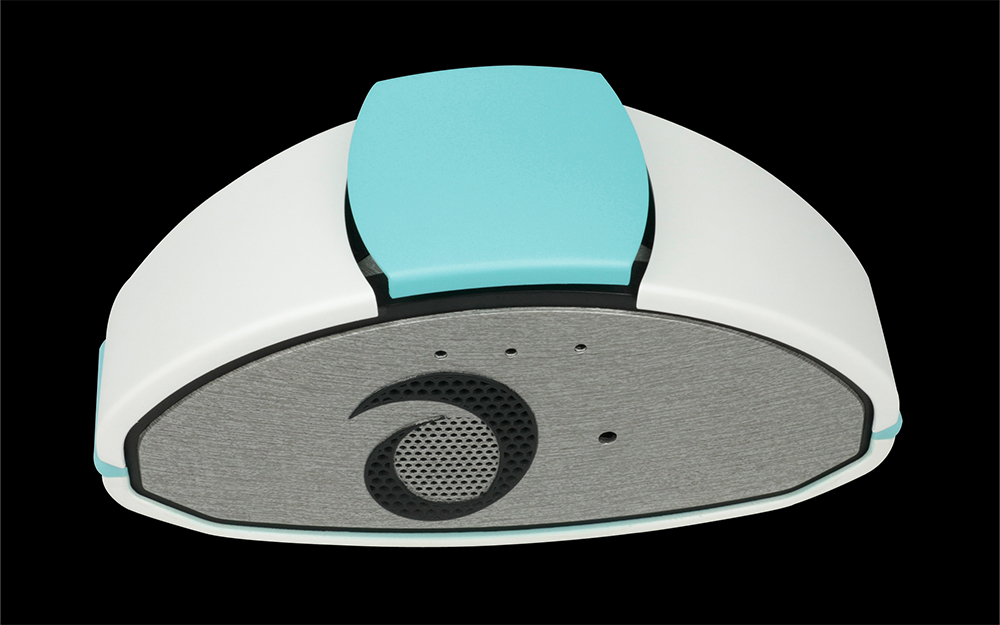

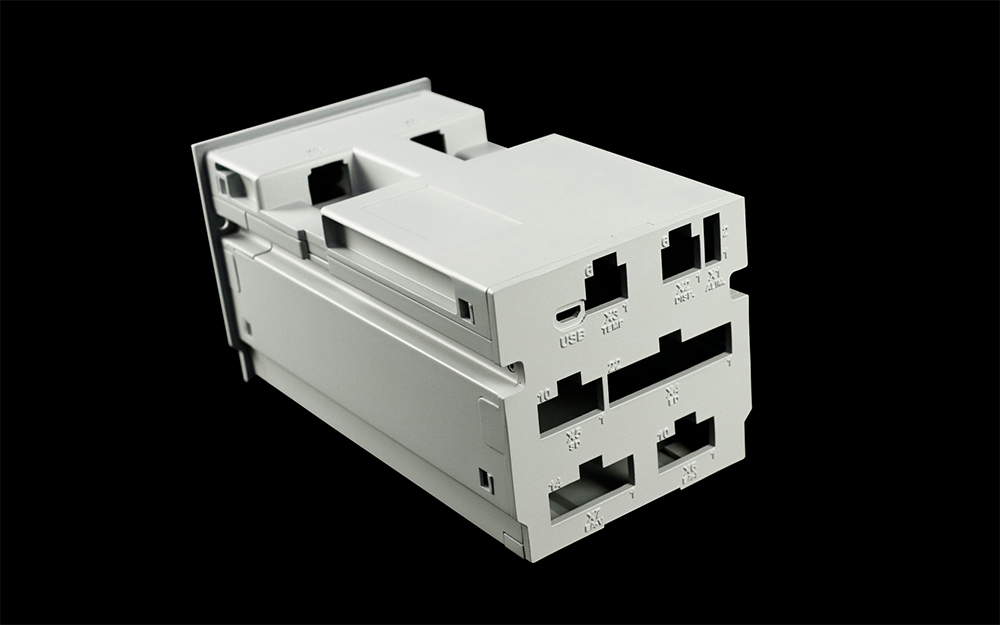

Explore the versatility of vacuum-casted plastic parts for prototyping and small-series production projects.

Our vacuum casting materials characteristics

Your project in 6 steps

Get your plastic prototypes and production parts in no time. Here’s how we provide a personalized response to your needs without any setbacks.

Your quote

Upload files and specifications

DFM

Design optimization

Tooling

Mold production and first samples for approval

Production

Close follow-up

Quality control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

Vacuum casting FAQs

Is vacuum casting good for functional prototypes?

There is a diverse range of polyurethane resins capable of replicating various mechanical and thermal properties. However, it’s important to note that these materials have limitations, particularly in terms of mechanical and thermal resistance.

Are molds reusable?

It is possible to make between 15 and 20 casts, depending on complexity. However, the mold has a limited lifespan of two months, after which it is no longer usable.

Are vacuum casting materials durable?

Yes, totally. The durability varies depending on the specific resin used. Some polyurethanes are formulated for high impact resistance and longevity, while others may be more suitable for short-term use.

Related resources

Extrusion Guide

Racing car bodywork for one of the world’s premier auto shows