Sheet metal materials

Sheet metal is commonly fabricated from various types of metals and alloys to create a wide range of products. Protolis provides a wide range of metal grades for prototyping and on-demand manufacturing of metal parts, including:

- 12+ production grades ready for use

- Specific grades on demand: Access the right material for your metal sheet part needs

- Customization: Choose from a diverse range of surface treatments for aesthetic and functional possibilities

Common sheet metal materials

Learn more about the many different types of materials available for sheet metal fabrication.

Description

This grade is carbon steel containing up to 0.4% silicon and 1.2% manganese. It is a general-purpose steel when high strength and high resistance are required.

Applications

Architectural (building, bridges, railway)

Industrial

Automotive

Description

This grade is low-alloy steel that shows good overall combinations of strength, toughness, fatigue strength, and moderate corrosion resistance.

Applications

Automotive

Hydraulic tools

Aerospace

Oil and gas industries

Agricultural

Description

This is a lightweight grade offering great strength and ductility, making it ideal for use in structural applications.

Applications

Energy

Construction

Industrial manufacturing

Description

This grade has the highest thermal conductivity among wrought carbon or non-alloy steels with fairly low electrical conductivity and low tensile strength.

Applications

Home appliances

Furniture

Automotive

Description

This material is excellent for flat cold forming products. It have several grade classified according to the maximum permissible yield strength. This grade is intended for easy forming by bending or moderate drawing.

Applications

Domestic appliances

Sanitary ware

Architectural panels

Signage

Description

Part of the same of the group as DC01EK, this grade is intended for more difficult deep drawing operations.

Applications

Domestic appliances

Sanitary ware

Architectural panels

Signage

Description

Part of the same of the group as DC01EK, this grade has excellent rheological and mechanical properties and can be used for forming very complex parts.

Applications

Domestic appliances

Sanitary ware

Architectural panels

Signage

Description

This alloy is a common grade for general sheet metal application where moderate strength is required. This aluminum is known for its excellent corrosion resistance, high ductility, and highly reflective finish.

Applications

Building

Signage

Furniture

Bridges and support structures

Interior designs

Description

This is the most popular aluminum alloy containing magnesium and silicon. The alloy is appreciated because of its versatile performance and all-round mechanical properties. It shows excellent machinability and natural corrosion resistance.

Applications

Transport

Marine

Construction

Aerospace

Architectural decoration

Description

This grade is the most versatile and widely used stainless steel with the addition of 18% chromium and 8% nickel. It has excellent mechanical properties and corrosion resistance.

Applications

Food processing

Automotive

Aerospace

Chemical

Description

This grade is a very popular strengthened copper alloy with 36% zinc. The alloy has good cold forming properties and an interesting price due to the high zinc content.

Applications

Architecture

Automotive

Hardware

Electrical

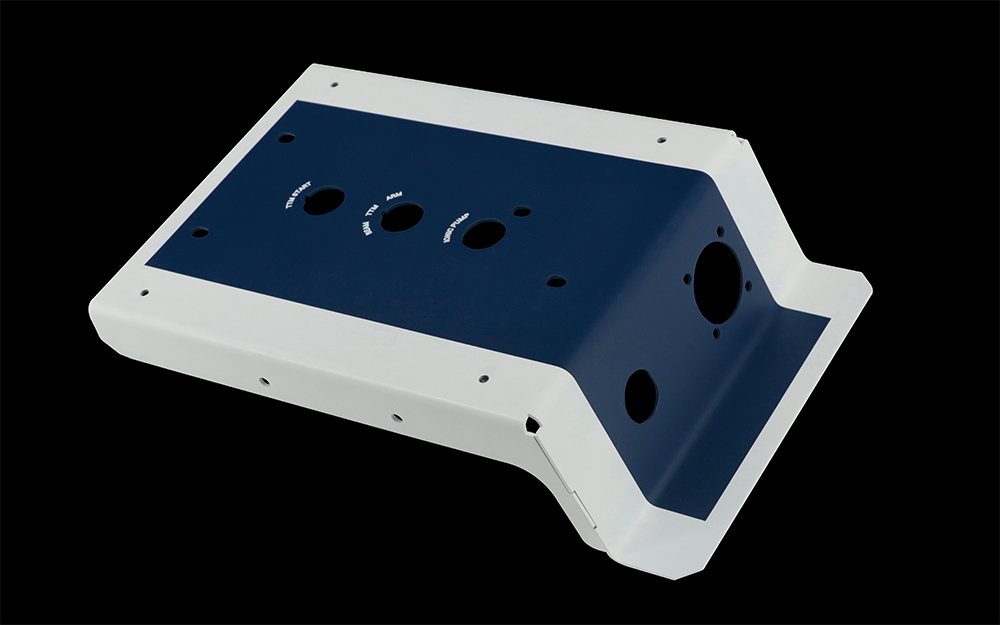

Sheet metal services

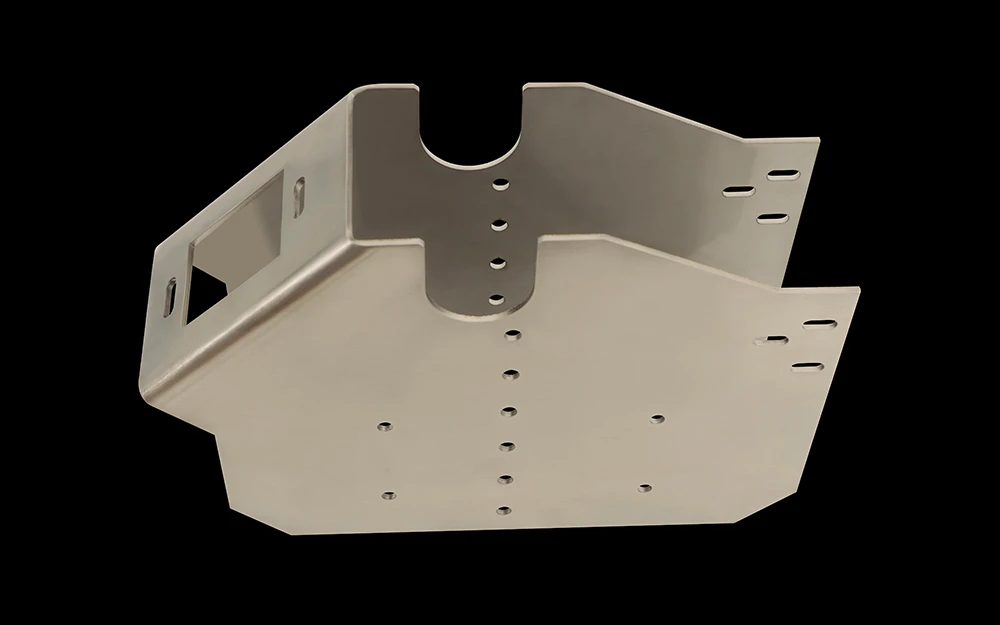

Sheet metal fabrication involves the transformation of a flat metal sheet into a three-dimensional part. The process begins with sheet cutting, known as blanking, followed by shaping the blank through stretching, punching, or bending to achieve the desired form.

At Protolis, you will work with experts to find the right fit for your project from a wide range of sheet metal fabrication processes, including materials grades and post-processing options.

Sheet metal services

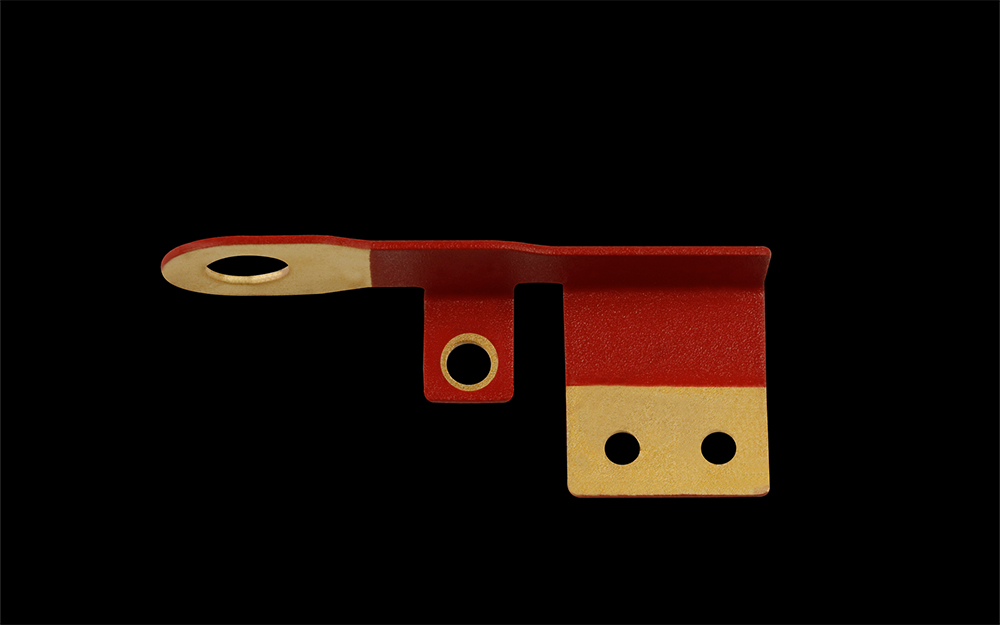

Our finishes for sheet metal fabrication

Our selection of metal sheet parts comes with a variety of finishing options, such as powder coating, polishing, brushing, and sandblasting.

Powder coating is similar to liquid spray paint, except that this process uses a dry powder. It improves the resistance to wear and corrosion. The resulting surface is uniform.

Brushing is a surface finishing method that forms continuous paralleled lines on the surface of metal parts. The purpose is usually to obtain a decorative effect with a slight level of reflection.

The type 2 and type 3 processes we provide are chemical (electrolyte) processes based on sulphuric acid that create an oxide layer. They protect parts from corrosion, increase their durability, and make the parts dielectric and non-conductive.

To learn more about these finishing options, please refer to our finishes page here.

Our sheet metal materials characteristics

Your project in 5 steps

Work with Protolis to get your sheet metal prototypes and production parts in no time. Here’s how it works.

Your quote

Upload files and specifications

DFM

Design optimization

Production

Close follow-up

Quality control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

Sheet metal FAQs

What are the thickness ranges available for different sheet metals?

Thickness can vary widely depending on the metal type. Common ranges are from thin sheet of less than 0.2 mm / 0.008 in to plates up to 5 mm / 0.2 in generally.

What methods are used for forming sheet metal?

- Bending: This process involves deforming metal around a straight axis. It’s achieved using a brake press that has a punch (upper tool) and a V-shaped die (bottom tool).

- Deep drawing: This is a process in which sheet metal is drawn into a forming die by the mechanical action of a punch. It is used to create objects like cups, cans, and sinks.

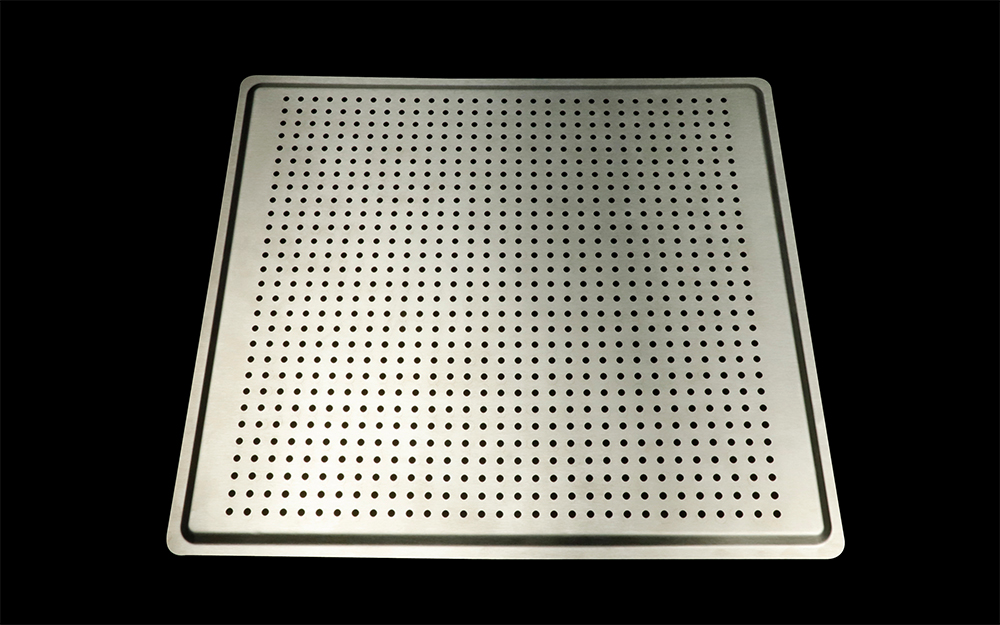

- Punching: This involves using a punch and die to create holes in the sheet metal. The metal is placed between the two, and the punch is forced into the die, shearing a portion of the metal to create a hole.

- Blanking: Similar to punching, but the primary purpose is to create a piece of metal that will be used in another process, not the hole. The “blank” is the piece of metal that is cut out and is the desired part.

- Stamping: A versatile process that involves placing sheet metal into a press tool where it’s subjected to one or multiple stations to perform various operations (punching, bending, embossing, flanging, etc.) in succession to form a desired part.

- Embossing: This involves creating raised or sunken designs or relief in sheet metal. The metal sheet is pressed between two dies, where one die has a raised design and the other has the corresponding indented design.

- Laser cutting: Not a forming method as such, but a way to cut and shape sheet metal using a focused laser beam to melt, burn, or vaporize the material, providing high precision and repeatability.

What finishes options are available?

Various finishes options are available, including mechanical treatments like polishing and brushing, as well as surface treatments such as anodization and burnishing. These methods enhance both aesthetics and corrosion resistance, offering a comprehensive range of choices based on the type of metal and specific project requirements.

Related resources

Extrusion Guide

Racing car bodywork for one of the world’s premier auto shows