Plastic materials for 3D printing

In 3D printing, plastics offer a versatile solution and are particularly well-suited for small series and prototyping projects. Protolis provides an assortment of plastic grades, each tailored to offer distinct advantages.

- Availability: Plastic 3D printing materials come in various types, allowing for a wide variety of applications. Gain access to the right material for your specific 3D printing needs

- Customization: Choose from a diverse range of finishes for both aesthetic and functional possibilities

Common 3D plastics

Discover the possibilities of plastic materials for 3D printing.

Description

This grade is a high-performance semi-crystalline thermoplastic. It has excellent mechanical properties in terms of toughness and high strength, good resistant to heat, high temperature, abrasion, and wear. The chemical resistance is good with high dielectric strength.

Applications

Alternative to aluminum and steel in certain cases

Commonly used in transport and aeronautics

Description

This plastic has excellent mechanical properties, including high fatigue resistance and excellent chemical resistance. It a lighter alternative to aluminum and steel in certain use cases.

Applications

Alternative to aluminum and steel in certain cases

Commonly used in transport and aeronautics

Description

This is a general-purpose grade that offers excellent strength, thermal stability, and the ability to withstand steam autoclaving. It has the highest heat resistance with UL94 V0 certification.

Applications

Food production tools

Custom medical appliances

Aerospace and automotive parts

Description

This is a high-performance thermoplastic with superior mechanical properties, including a high strength-to-weight ratio. It has good FST (flame, smoke, and toxicity) resistance and good chemical resistance. It is a flame-retardant UL94V0.

Applications

Digital manufacturing

Rapid prototyping

Transportation

Aerospace

Description

This is an SLA transparent resin with similar properties to UTR 9000. It commonly used for parts with higher surface finishing requirements.

Applications

Master patterns

Concept models

General parts

Functional prototypes

Description

This grade is a synthetic thermoplastic polymer with the lowest melting point of all nylon. It has high strength, high elongation and flexibility, good chemical resistance, low friction, and good dimensional stability. It is also suitable for painting, impregnating, coating, and sandblasting.

Applications

Possible substitute for injection molding plastics (medical applications, automotive design, production parts).

Description

This resin is highly accurate and durable material. Commonly used for stereolithography, it has a medium viscosity, good strength and flexibility, and strong resistance to yellowing.

Applications

Master patterns

Concept models

General parts

Functional prototypes

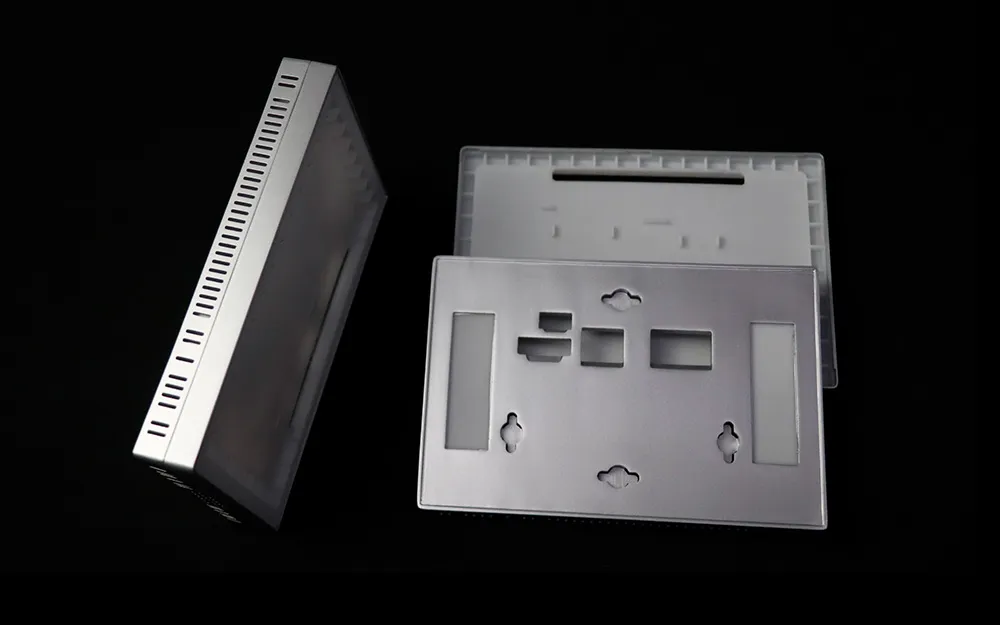

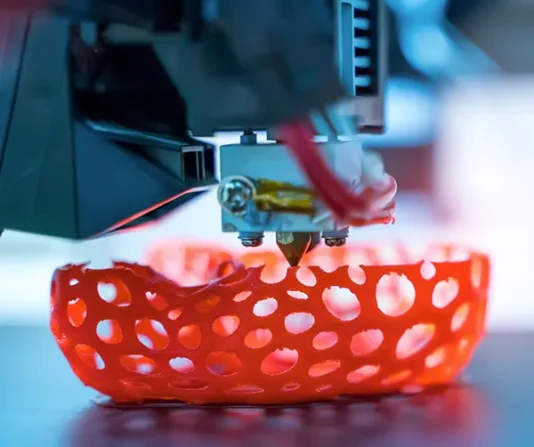

3D plastic printing services

3D printing, or additive manufacturing, creates precise complex plastic parts—including hollow and undercut components—using layer-by-layer material addition from digital models that surpasses traditional machining in speed and precision.

At Protolis, we offer plastic 3D printing services for low-volume manufacturing and rapid prototyping. That includes high-quality 3D production processes such as stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM).

3D plastic printing services

Our finishes for plastics 3D printing

Our selection of 3D printed plastics comes with a variety of finishing options, such as painting, technical or cosmetic polishing, and chrome plating.

The pigmentation process makes it possible to produce pieces naturally colored in the mass of certain plastics. It is possible to choose the desired RAL or Pantone, with color pigments mixed with the material. This is applicable for rigid or flexible parts.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

There are several degrees of transparency depending on the technologies and materials used. The opacity can also be manually adjusted by polishing, sanding, or pigmentation.

To learn more about these finishing options, please refer to our finishes page.

Our 3D printing plastics characteristics

FDM & SLS: DIN 7168-91, class m

FDM & SLS: DIN 7168-91, class m

Your project in 5 steps

When you work with Protolis, you can expect personalized service, clear communication, and rapid turnaround of your 3D plastic prototypes and production parts. Here’s how it works.

Your quote

Upload files and specifications

DFM

Design optimization

Production

Close follow-up

Quality control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

3D printing plastics FAQs

Why use 3D Printing for your prototyping project?

The main advantages of 3D printing include speed, design freedom, and minimal technological and preparatory constraints. It is cost-effective for low volumes, providing design flexibility, a variety of materials, and few design constraints.

What plastic can be used for 3D Printing?

The range of plastics used in 3D printing is constantly evolving. Today, there are many plastic options with different properties, available in various forms such as filament or powder, depending on the technology used. The main plastics available include ABS, PLA, PETG, nylon, TPU, TVA, and HEPS, as well as several types of possible resins in SLA.

Is PLA good for prototyping?

Yes, PLA is a very popular choice. It’s inexpensive, easy to print, cost-effective, and has good dimensional stability, along with a pleasing aesthetic and finish. It’s also biodegradable. However, it comes with limitations in terms of mechanical and thermal properties, and it tends to yellow over time. Its lifespan is not very long.

Related resources

Extrusion Guide

Racing car bodywork for one of the world’s premier auto shows