Materials for extrusion

Extrusion is a versatile manufacturing process that can be applied to both metal and plastic materials. Protolis provides a wide range of grades for plastic and aluminum extrusion profiles prototype, each tailored to offer distinct advantages.

- Production material available for small batches

- 8+ grades available, all ready for extrusion

- Specific grades available on demand: Gain access to the specific material for your extrusion parts needs or projects

- Customization: Choose from a diverse range of colors and finishes for both aesthetic and functional possibilities

Our plastics and aluminum extrusion materials

Discover the possibilities of materials for prototypes extrusion.

Description

This is the most popular aluminum alloy containing magnesium and silicon. The alloy is appreciated because of its versatile performance and all-around mechanical properties. It also shows excellent machinability and natural corrosion resistance.

Application

Yachts, boats, and aircraft structures

Structural components

Pipe fittings

Wheels and various transportation end uses

Automotive components

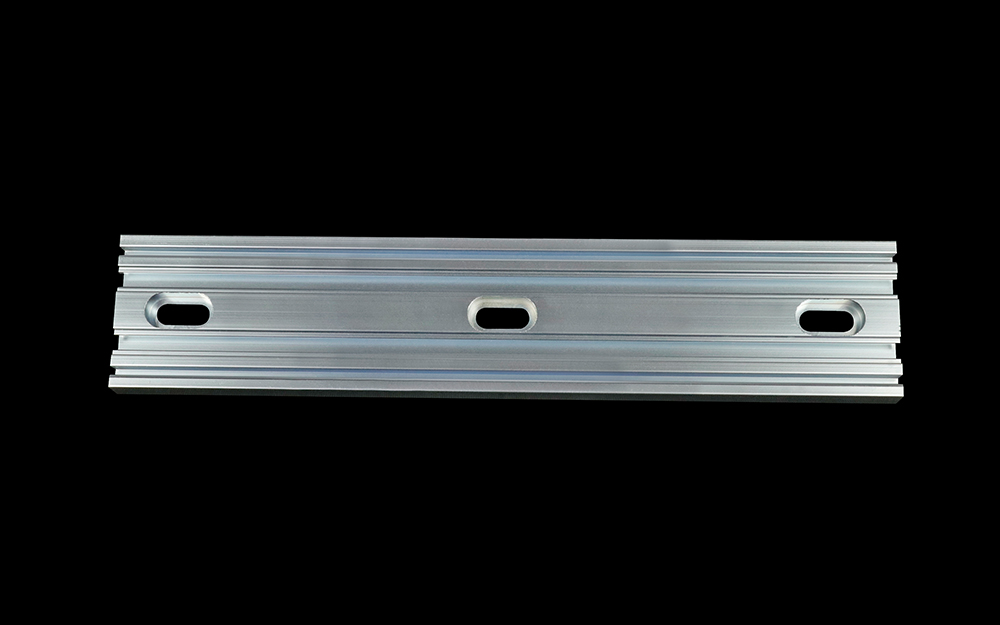

Description

This medium strength alloy, commonly known as an architectural alloy, has high corrosion resistance, can be easily anodized, and is suitable for welding. It features medium mechanical properties (with the lowest tensile strength among the 6000-series) and a good surface finish.

Application

Window frames

Door frames

Roofs

Sign frames

Description

Acrylonitrile Butadiene Styrene is affordable, light weight, strong, rigid, resilient thermoplastic material plastic. It offers impressive impact resistance, stiffness, and strength. It also boasts good dimensional stability and low water absorption. Additionally, it is easy to paint and electroplate.

Application

Construction

Plumbing

Marine

Furniture industries

Description

Acrylic is often used as a glass substitute as it offers excellent optical clarity and high impact resistance. Additionally, it offers high resistance to scratch and is UV and weather-resistant. Moreover, it provides good dimensional stability and low water absorption, and it is easy to paint and electroplate.

Application

Lighting diffusers, refractors and lenses

Display shelves, racks and trims

Vehicle trims

Menu holders

Description

Polypropylene stands out as one of the lightest thermoplastics obtainable, offering outstanding flexibility as well as chemical resistance (most alkaline and acidic substances) at low cost. Moreover, it demonstrates low moisture absorption and non-toxic properties.

Application

Oil pump tubes

Protective plant and tree sleeves

Polypropylene parts for toys

Handles and shafts

Food grade tubing and sample tubes

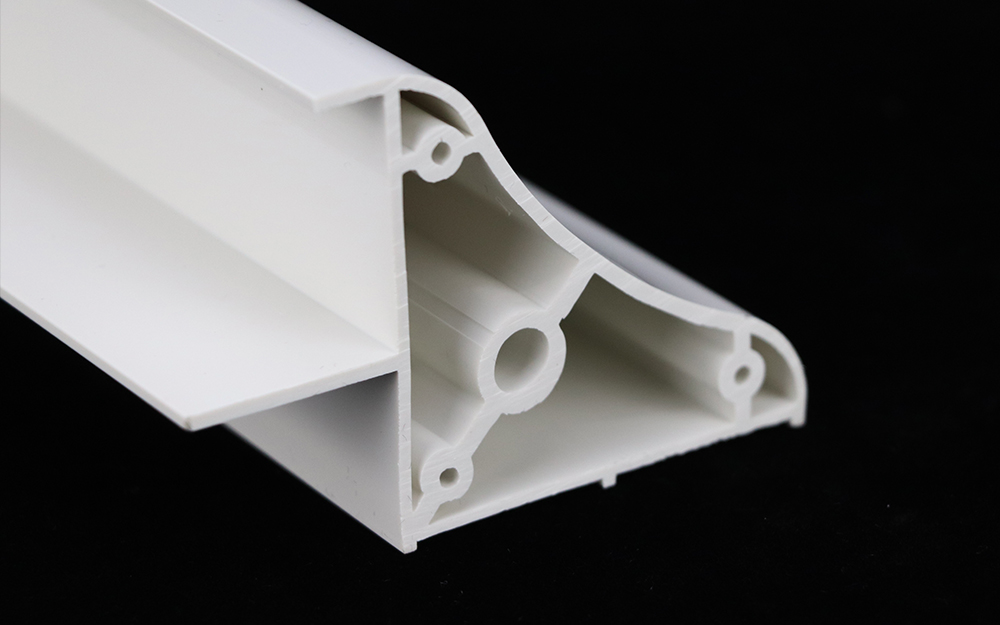

Description

Vinyl chloride provides a good balance of stiffness, impact resistance, UV stability, and inherent UL flame performance. Rigid PVC is also chemically resistant to acids, salts, bases, fats, alcohols, and many solvents.

Applications

Window and door frames

Plumbing and fittings

Irrigation elements

Refrigeration component

Protective bumpers

Description

Flexible PVC is made with the addition of plasticizers, which allows for a softer material. It offers good weather resistance, tear strength, and kink resistance at a low cost.

Applications

Tubes and hosing

Gaskets and seals

Bumpers

Cable insulation

Water stops

Sleeves

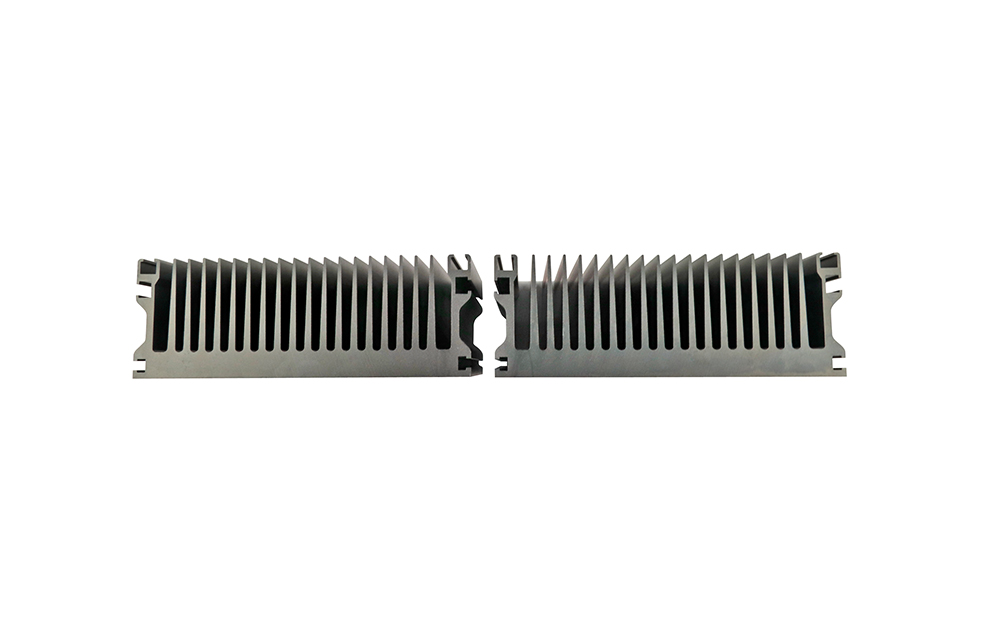

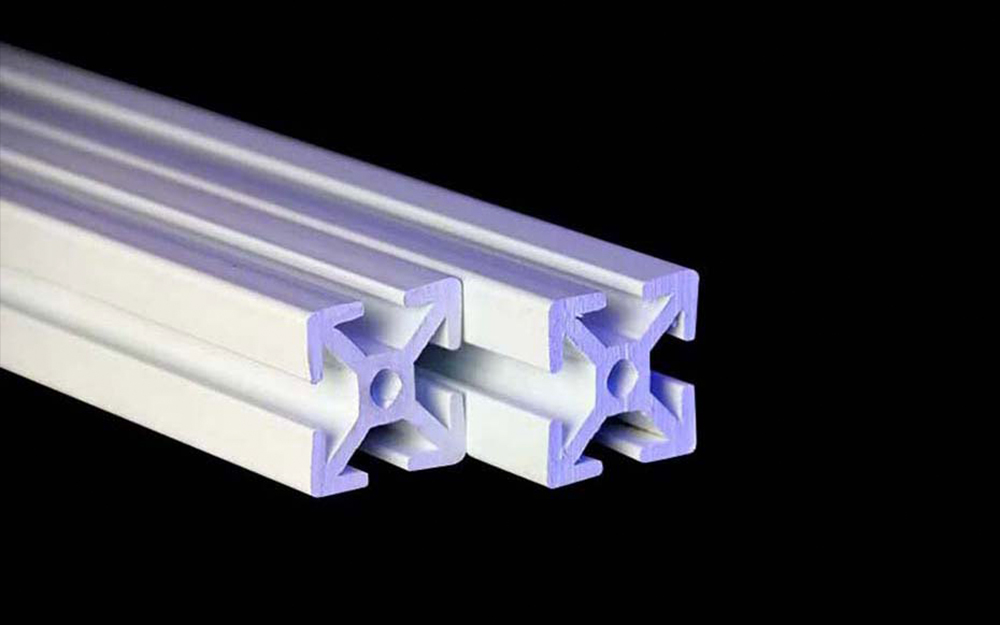

Extrusion services

Extrusion consists of shaping an aluminum alloy or plastic material into a specific cross-sectional profile that meets your specifications. The material (plastic or aluminum) is inserted into a cylinder (matrix) and then pressed through an extrusion die to give it the desired shape.

At Protolis, we offer extrusion services to produce your custom plastic and aluminum profiles for prototyping and low-volume production purposes.

Extrusion services

Our finishes for extrusion

Our selection of extruded aluminum and plastics profiles comes with a variety of finishing options. Select your preferred finishing option for enhanced functionality and aesthetics.

The type 2 and type 3 processes we provide are chemical (electrolyte) processes based on sulphuric acid that create an oxide layer. They protect parts from corrosion, increase their durability, and make the parts dielectric and non-conductive.

This polishing generally involves changing the level of roughness of a surface by various manual, mechanical, or chemical techniques. This can change the dimensional or geometric accuracy of the part.

There are several degrees of transparency depending on the technologies and materials used. The opacity can also be manually adjusted by polishing, sanding, or pigmentation.

Applications

Explore the versatility of plastic and aluminum profiles for prototyping and small series production projects.

Our extrusion metals and plastics characteristics

Your project in 6 steps

Choose Protolis and get your extruded prototype or production parts in no time.

Your quote

Upload files and specifications

DFM

Design optimization

Tooling

Mold production and first samples for approval

Production

Close follow-up

Quality control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

Extrusion FAQs

Are recycled or eco-friendly materials available for extrusion?

Depending on the application, recycled materials can be used. However, they may need to be carefully processed to ensure quality and consistency.

Can materials be custom formulated for my extrusion needs?

Although materials can be custom formulated to meet specific requirements, Protolis does not offer this option and will instead propose a standard grade for your project.

What materials should I use for extrusion?

The material you should use for extrusion depends on the desired properties of the finished product, the application, and the extrusion process itself. Both metals and polymers can be extruded, and there’s a wide range of materials within each category suitable for extrusion. In metal extrusion, the most commonly used materials is aluminum for its lightweight and corrosion resistance. In plastic extrusion, thermoplastics like polypropylene, polyethylene, PVC, and polystyrene are widely used due to their ease of thermal processing and versatility.

What at the major materials used in the extrusion process?

For metals, Aluminum takes the forefront as the preferred choice, thanks to its widespread popularity. Aluminum alloys are prized for their exceptional strength-to-weight ratio, corrosion resistance, and versatility. Specifically, we often employ the 6061 and 6063 grades of aluminum in our projects.

When it comes to plastics, PVC (polyvinyl chloride) emerges as the dominant extrusion material. PVC is renowned for its cost-effectiveness, achieving a favorable equilibrium between performance and affordability. Furthermore, PVC showcases robustness and resilience against impact, weathering, chemicals, and UV radiation.

Related resources

Extrusion Guide

Overview of Medical Device Regulations [Guide]