Plastics materials for CNC machining

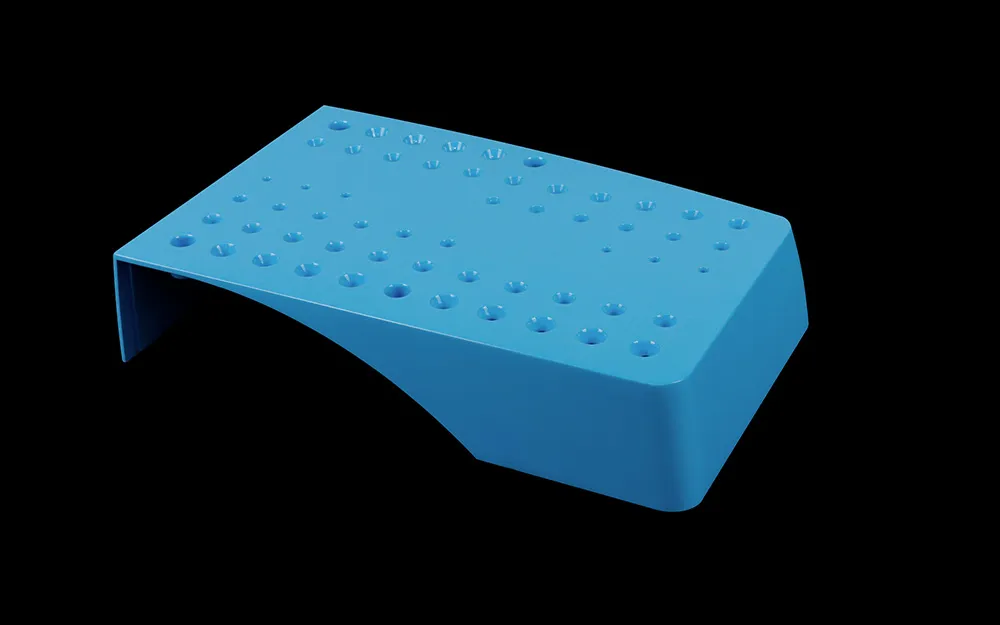

Plastic machining offers a versatile and cost-effective solution, particularly well-suited for one-off prototypes and custom end-use parts. Protolis provides a comprehensive selection of grades, each tailored to offer distinct advantages.

- 18+ grades (e.g. CNC ABS, CNC acrylic, etc.) in stock, ready for CNC machining.

- Customization: Choose from a diverse range of colors and finishes for both aesthetic and functional possibilities.

- Specific grades on demand: Gain access to the right material for your specific CNC machining needs.

Common CNC plastics

Discover the possibilities of plastic materials for CNC machining.

Description

Acrylonitrile Butadiene Styrene (ABS) is a low-cost plastic that is easy to machine, offering good impact resistance, stiffness, and strength. It also boasts good dimensional stability and low water absorption, along with excellent machinability and bonding properties, making it suitable for painting and electroplating.

Applications

General household items: gardening tool, toys, kitchen appliances, electrical/electronic appliances

Widely use for pre-production prototype of housings, covers and structural components

Description

Plastic blend of ABS & PC, the properties are controlled by the ratio of PC & ABS. It includes the benefits & limitations of both. The durability of ABS plus the impact strength of PC makes the compound bendable but not easy to break.

Applications

Similar to ABS applications requiring better impact strength.

Electrical/electronic product shell

Automotive interior

Description

LDPE shares most of the characteristics of HDPE, but it is softer, more flexible, and more likely to crack under stress.

Applications

Household applications (hinges)

Electronic appliances

Food packaging and container

Description

Polycarbonate is a good alternative to glass with its high transparency, high resistance to impact and temperature, good electrical insulation, and excellent dimensional stability. It also has low water absorption, good machinability and bonding, and is easy to paint or electroplate.

Applications

Applications requiring transparency and high impact resistance

Exterior and interior automotive parts

Exterior lighting

Description

Kown as acrylic, PMMA is one of the clearest plastic, lighter alternative to glass, and economic substitute for PC but with lower impact strength.

High resistance to scratch, UV & weather resistant.

Good dimensional stability, low water absorption.

Good machinability and bonding, easy for paint and electroplating.

Applications

Construction outdoor applications

Automotive light parts

Electronic screens

Cosmetic packaging and display

Description

This thermoplastic has high strength, stiffness, and toughness, as well as excellent bearing, wearing, and sliding properties. It is resistant to impacts and temperature and has strong chemical resistance (hydrocarbons and solvents), good dimensional stability, and low moisture absorption.

Applications

Commonly used in bushings, rollers, wear strips, gears, and pump parts

Description

Polypropylene is one of the lightest thermoplastics available with excellent resistance to fatigue and chemical resistance (most alkaline & acid)

Low moisture absorption and non-toxic.

Applications

Packaging industry

Household appliances

Eelectric appliances

Automotive decorative parts

Description

Polyethylene terephthalate is a plastic with high mechanical strength, excellent wear resistance and good sliding properties. It also has excellent chemical resistance, good dimensional stability, very low moisture absorption, and is a good electrical insulator.

Applications

Accurate automotive parts

Electronic appliances

Domestic appliances

Food packaging

Description

High-density polyethylene is a lightweight and flexible plastic with good resistance to impacts, breaks, and abrasion. It’s an effective electrical insulator and has excellent resistance at low temperatures, as well as good chemical resistance, good dimensional stability, and low moisture absorption.

Applications

Construction (pipes, tanks, water storage)

Mechanical equipment parts

Electronic appliances

Food packaging and containers

Description

Ultra-high-molecular-weight polyethylene, also called HDPE 1000, has a unique combination of wear and corrosion resistance, low surface friction, and impact strength. It also offers good electrical insulation, high chemical resistance, good dimensional stability, and no moisture absorption

Applications

Mechanical and electrical engineering

Construction industry

Food industries

Description

Polyvinyl chloride is a polymer with normal impact strength and good tensile strength and stiffness. It offers exceptional chemical and corrosion resistance, good dimensional stability, no water absorption, and good machinability and bonding. It is also self-extinguishing.

Applications

Construction industry (pipes, windows and doors frames)

Automotive parts

Medical devices

Description

Polyamide, also called nylon, is a light plastic with good tensile strength and stiffness (comparable to metal) as well as excellent resistance to bearing, fatigue, and abrasion. It offers excellent corrosion resistance and electrical properties, with good machinability.

Applications

Construction material

Automotive parts

Aircraft parts

Electronic and electrotechnical parts

Description

The chemical and physical properties of PA66 are similar to those of PA6, though PA66 shows slightly lower water moisture absorption, higher mechanical properties, and better short-term heat resistance.

Applications

Construction materials

Automotive parts

Aircraft parts

Electronic and electrotechnical parts

Description

Polybutylene terephthalate is a engineering thermoplastic with excellent mechanical (high strength and toughness) and electrical insulation. It has good resistance to UV and chemicals, a wide range of temperature usage (-40℃ to 110°C) as well as high dimensional stability, low moisture absorption, and good machinability.

Applications

Food industry

Electrical and electronic appliances (connector strips, insulating housing)

Household appliances

Medical equipment

Description

Polytetrafluoroethylene, also known as Teflon, is a thermoplastic polymer with excellent chemical resistance, wear resistance, and an extremely low friction coefficient. It offers excellent electrical insulation, no water absorption, and good UV resistance. It is also self-extinguishing and naturally flame retardant (UL 94-V0).

Applications

Chemical industry (temperature sensor casing, gaskets, chemical tanks)

Medical applications

Fire equipment

Description

Polyetheretherketone is high-performance thermoplastic with excellent chemical resistance, low moisture absorption, excellent tensile strength, and good resistance to wear, abrasion, and fatigue. It also has high-temperature resistance and natural UL94 V-0 (low-toxicity gas if burnt), as well as good dimensional stability and good machinability.

Applications

Used in many of the most critical areas in general industries: automotive, marine, medical, aerospace

Description

Polyphenylene sulfide is advanced engineering plastic with properties similar to metal with exceptionnal mechanical strenght, excellent wear resistance and fatigue endurance.

Good electrical insulation. High-temperature resistance and naturally UL94 V-0 .

Exceptionnal chemical resistance and no moisture absorption.

Good dimensional stability and good machinability.

Applications

Automotive: seals, fuel and brake systems

Mechanical engineering: pump and valve components

Electrical/Electronic components: connectors, contact rails,

Medical industry

CNC plastic machining services

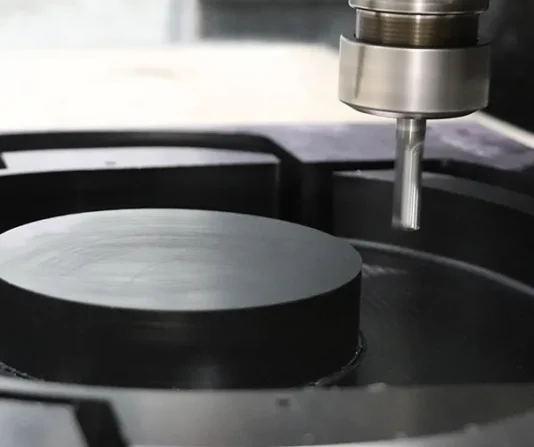

Plastic machining using CNC is a sophisticated process that involves the utilization of computer-controlled machinery to achieve precise and intricate shapes from plastic workpieces. CNC plastic cutting, in particular, is a highly accurate manufacturing procedure wherein part of plastic polymer is removed from a plastic part to attain the intended form or configuration.

At Protolis, we boast an extensive array of cutting-edge machinery that is custom-tailored to accommodate your distinct requirements. Our comprehensive equipment lineup encompasses CNC 3 & 5 axis milling , CNC drilling, CNC turning, and the advanced capabilities. This enables us to cater to a wide spectrum of manufacturing demands while upholding the highest standards of precision and quality.

CNC plastic machining services

Our finishes for plastics CNC machining

Our selection of CNC machined plastics parts comes with a variety of finishing options, such as painting, technical or cosmetic polishing and chrome plating.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

There are several degrees of transparency depending on the technologies and materials used. The opacity can also be manually adjusted by polishing, sanding, or pigmentation.

Chrome plating is a technique of applying a thin layer of chromium onto a substrate through galvanic or vacuum plating. This additional layer not only improves the aesthetic but prevents corrosion and wear.

Whether by applying a surface treatment or by pigmentation, matching the colors of your prototypes and parts is important for meeting your specifications and the visual quality of the final product.

The pigmentation process makes it possible to produce pieces naturally colored in the mass of certain plastics. It is possible to choose the desired RAL or Pantone, with color pigments mixed with the material. This is applicable for rigid or flexible parts.

To learn more about these finishing options, please refer to our finishing page here.

Applications

Explore the versatility of plastics CNC machining for prototyping and small series production projects.

Our CNC plastics characteristics

Your project in 5 steps

Get your CNC plastic prototypes and production parts in no time with Protolis. Here’s how our client projects typically work.

Your quote

Upload files and specifications

DFM

Design optimization

Production

Close follow-up

Quality control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

CNC machining plastic FAQs

What plastics can be used in CNC machining?

CNC machining can accommodate a wide range of plastics. Typically, acetal (POM), acrylic (PMMA), nylon (PA), polycarbonate (PC), polypropylene (PP), polyethylene (PE), PVC (polyvinyl chloride) are the most commonly requested by our customers. It is important to know that certain harder plastics require special considerations during machining to be successfully machined.

Which plastic is the right material for me?

Selecting a plastic grade requires evaluating its ability to meet your mechanical and surface finish requirements. This must be balanced with the feasibility of manufacturing the part using CNC machining, as not all shapes can be easily produced. The goal is to find the right compromise by focusing on the most critical characteristics for your application.

Which information shall I give to start my project?

You just need to give us your 3D CAD file. To start, simply select a manufacturing process, raw material, finishing option, and upload a 3D CAD file here (choose the right anchor text to link here)

Related resources

Extrusion Guide

Racing car bodywork for one of the world’s premier auto shows