Zamak for CNC machining

Zamak is zinc-based alloys generally composed of a blend of zinc, aluminum, magnesium, and copper. It is known for its many advantages, including:

- Non-toxic and hypoallergenic

- Strong and durable

- Economical choice

Available grades

CNC zamak machining involves using different grades of alloys, each with specific properties and advantages.

Description

Zamak alloys are mainly composed of zinc, aluminum, and magnesium. This grade has 4% aluminum and is the most widely used zinc alloy. It provides an excellent combination of physical and mechanical properties with a good dimensional stability.

Applications

Automotive

Construction (plumbing)

Electrical

Description

This alloy is similar to Zamak 3 with some additional copper, which results in improved mechanical properties but slightly reduces ductility.

Applications

Automotive

Construction (plumbing)

Electrical

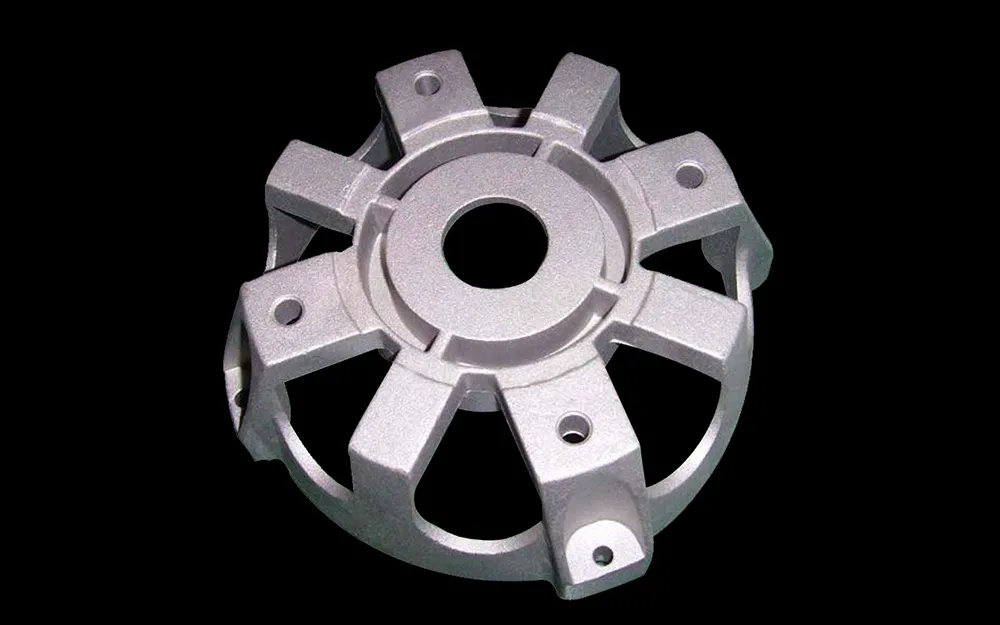

Industries using CNC machined zamak components

Zamak is commonly used for low-volume production and prototyping of a wide range of products and parts. Our competencies and capabilities in zamak are helping an extensive variety of industries for numerous applications:

- In automotive, for gears, brackets, and electrical connectors

- In medical, for surgical instruments and orthopedic implants

- In aerospace, for fasteners, brackets, and housings

- In consumer goods, for door handles, locks, and decorative items

- In electronics, including switches, connectors, and housings

Industries using CNC machined zamak components

Our finishes for zamak

Our selection of CNC machined zamak comes with a variety of finishing options, such as bead blasting, powder coating, polishing, brushing, and sandblasting.

This polishing generally involves changing the level of roughness of a surface by various manual, mechanical, or chemical techniques. This can change the dimensional or geometric accuracy of the part.

Sand blasting is the high-pressure projection of silica sand on the surface of the workpiece to create a matte surface, including creating aesthetic consistency for plastic and metallic parts.

Powder coating is similar to liquid spray paint, except that this process uses a dry powder. It improves the resistance to wear and corrosion. The resulting surface is uniform.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

Brushing is a surface finishing method that forms continuous paralleled lines on the surface of metal parts. The purpose is usually to obtain a decorative effect with a slight level of reflection.

Our CNC zamak characteristics

Your project in 5 steps

If you need to get your zamak prototype or production parts in no time, rest assured that Protolis is a flexible organization providing personal responses—without any setbacks.

Your Quote

Upload files and specifications

DFM

Design optimization

Production

Close follow-up

Quality Control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

CNC Machining Zamak FAQs

What grades of zamak can be machined?

All grades of zamak can be machined, but some grades are more commonly used for machining than others due to their specific properties. Zamak 3 is the most popular and widely used zamak alloy, primarily because of its excellent balance of desirable physical and mechanical properties. It’s known for its good machinability, making it a common choice for die-casting and machining operations.

What is the difference between zamak 3 and zamak 5?

Zamak 3 and zamak 5 are both members of the zinc-alloy family, with the primary distinction being their copper content. Zamak 3 is the most prevalent variant and contains minimal copper, usually under 0.005%. In contrast, zamak 5 has around 1% copper, granting it enhanced strength and hardness compared to zamak 3. However, this added strength in zamak 5 comes at the cost of a slight reduction in ductility. The increased copper in zamak 5 often results in a finer surface finish. Typically, zamak 3 is favored for general applications like toys and decorations, while the stronger zamak 5 is selected for applications demanding higher mechanical resilience, such as in automotive or electrical components.

How much does it cost to CNC machine zamak parts?

Compared to other metals, CNC machining zamak is typically more cost-effective, especially when considering the lifespan of tooling and the material’s castability, which reduces the amount of machining needed.

Related Resources

CNC Machining Guide

Overview of Medical Device Regulations [Guide]