Stainless steel for CNC machining

Stainless steel is a type of steel that contains at least 10.5% chromium in its composition, which forms a protective oxide layer on its surface. This gives it the following advantages:

- Corrosion and heat resistance, withstanding moisture, chemicals, and harsh environments

- Strength in applications with heavy loads and stresses

- Versatility across a wide range of applications and industries

Available grades

CNC stainless steel machining involves using different grades of alloys, each with specific properties and advantages.

Description

Stainless steel 316TI has the same composition as stainless steel 316, except with the addition of titanium. The presence of titanium improves its mechanical strength and wear resistance. As an alternative to 316L, it has better high temperature strength.

Applications

Construction

Chemical industry

Food protection

Medical

Description

This is a low carbon version of 316 stainless steel, offering superior corrosion resistance (most chemicals, salts, and acids).

Applications

Medical

Aerospace

Automotive

Marine

Description

This grade is the most versatile and widely used stainless steel with the addition of 18% chromium and 8% nickel. It has excellent mechanical properties and corrosion resistance.

Applications

Food processing

Automotive

Aerospace

Chemical

Description

This is a martensitic stainless steel grade known for its high hardness capabilities. It is often used in applications requiring good wear resistance and a fair degree of corrosion resistance. The carbon content in stainless steel 420 gives it its unique hardness properties. However, it is less resistant to corrosion compared to higher chromium stainless steels.

Applications

Medical

Automotive

Description

This grade is a high-carbon martensitic stainless steel. It is known for its high strength, moderate corrosion resistance, and very good hardness and wear resistance. These properties are due to its high carbon content. 440C is magnetic and can be heat-treated to achieve highest hardness levels of stainless steel.

Applications

Medical

Automotive

Description

This stainless steel is known for its high strength and excellent corrosion resistance. It contains lower levels of chromium and nickel compared to other austenitic grades like 304, with the addition of higher carbon content. This composition allows 301 to be more responsive to heat treatment, enabling it to achieve high strength and hardness levels through cold working.

Applications

Automotive

Structural

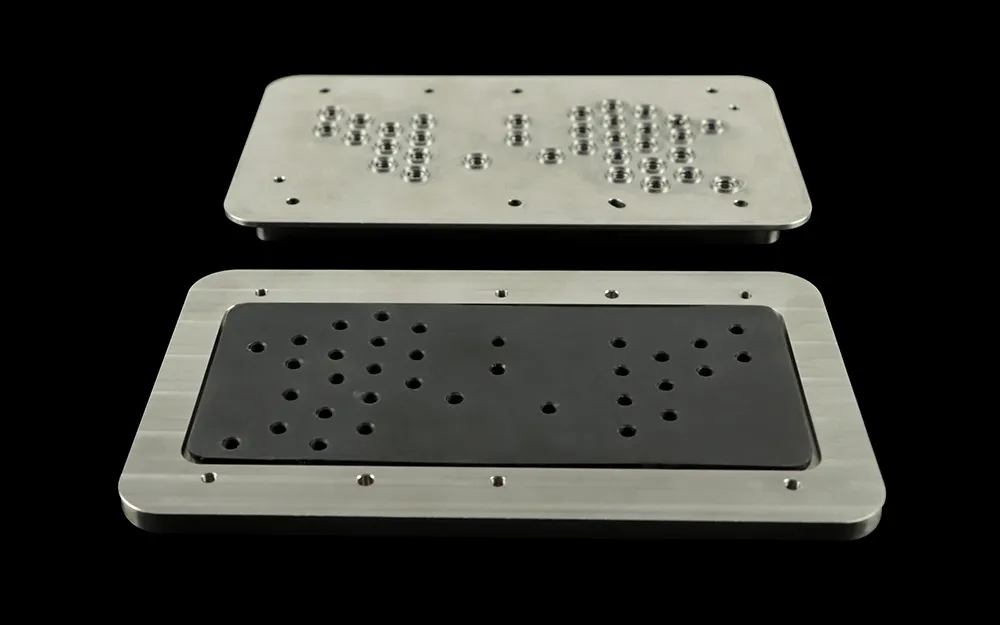

Industries using CNC machined stainless steel components

With its resistance to rusting and corrosion, stainless steel excels across diverse applications:

- Culinary uses: Widely used for cutlery, kitchen utensils, and cookware due to its corrosion resistance, hygiene, and durability

- Kitchen sinks: For its durability, resistance to stains, and ease of cleaning

- Marine: Essential in the marine sector, where exposure to saltwater and harsh environmental conditions is common

- Surgical tools and medical equipment: Indispensable in the healthcare sector for its biocompatibility, resistance to corrosion from sterilization processes, and ease of cleaning

Industries using CNC machined stainless steel components

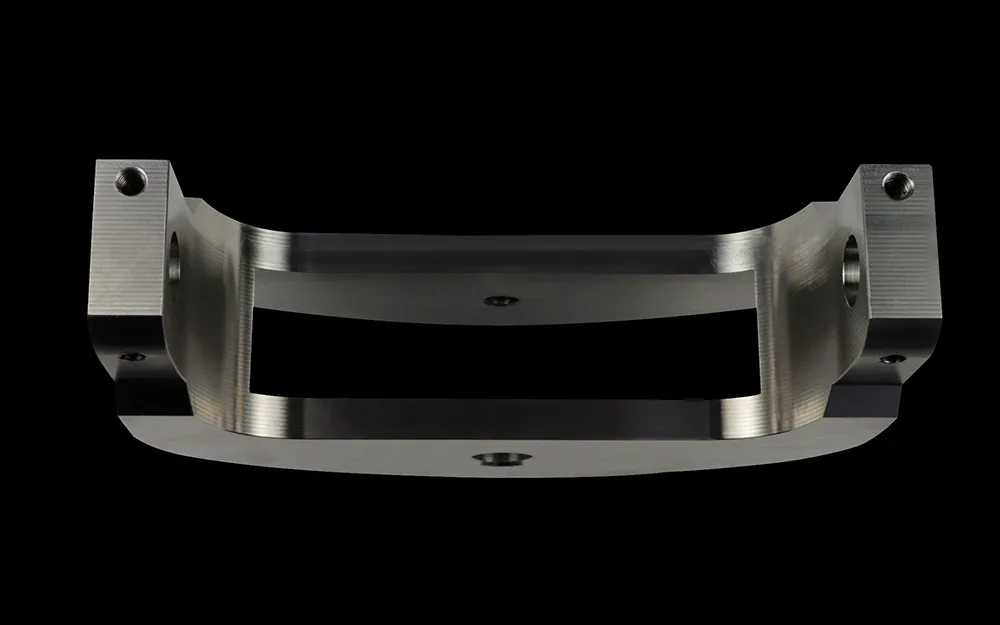

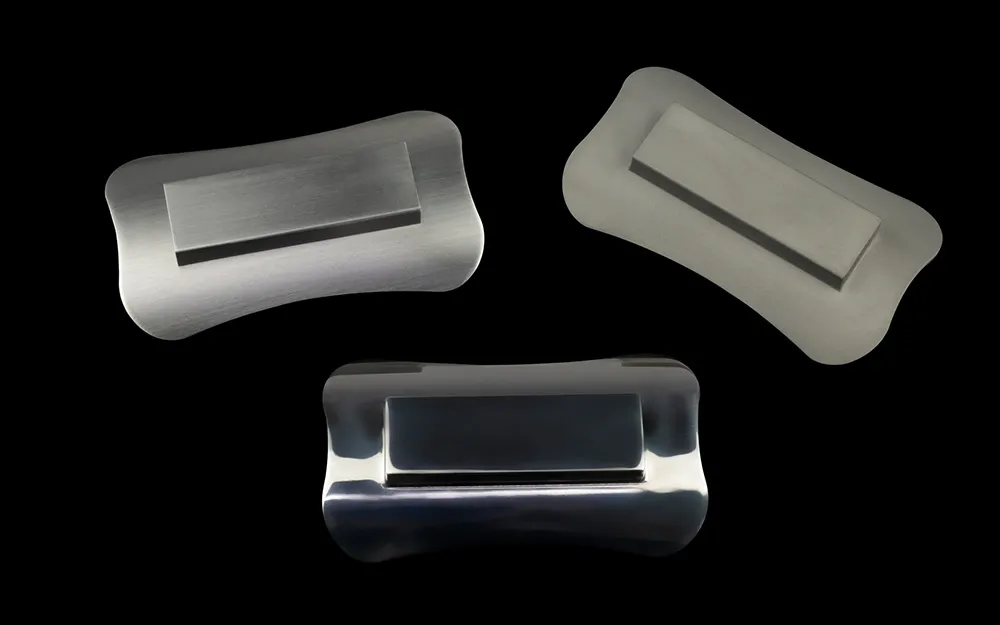

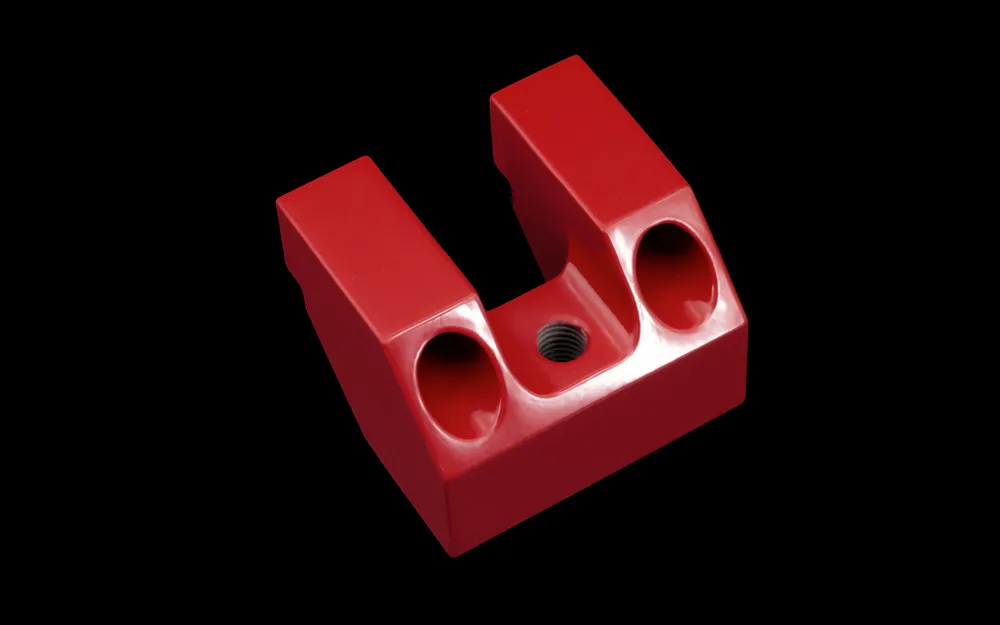

Our finishes for stainless steel

Our selection of CNC machined stainless steel parts comes with a variety of finishing options, such as powder coating, polishing, brushing, and sandblasting.

Brushing is a surface finishing method that forms continuous paralleled lines on the surface of metal parts. The purpose is usually to obtain a decorative effect with a slight level of reflection.

Sand blasting is the high-pressure projection of silica sand on the surface of the workpiece to create a matte surface, including creating aesthetic consistency for plastic and metallic parts.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

Powder coating is similar to liquid spray paint, except that this process uses a dry powder. It improves the resistance to wear and corrosion. The resulting surface is uniform.

This polishing generally involves changing the level of roughness of a surface by various manual, mechanical, or chemical techniques. This can change the dimensional or geometric accuracy of the part.

CNC stainless steel characteristics

Your project in 5 steps

Get your stainless steel prototype or production parts in no time with Protolis, a flexible organization that always provides a personal response.

Your Quote

Upload files and specifications

DFM

Design optimization

Production

Close follow-up

Quality Control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

CNC machining stainless steel FAQs

What stainless steel can be machined?

The machinability can vary depending on the grade composition, hardness, and other factors. The stainless steels that are encountered most frequently in machining applications are typically the austenitic types, exemplified by grades 304 and 316. These grades are known for their tendency to work harden rapidly and their limited effectiveness in breaking chips during machining.

How long does stainless steel CNC machining take?

Machining stainless steel typically takes longer than machining aluminum or brass due to its hardness and abrasiveness. The specific alloy within each metal category can impact machining times. Some stainless steel alloys are easier to machine than others, just as some aluminum or steel alloys may be more challenging to machine

What are the different kinds of stainless steel?

In addition to our extensive range of CNC machining solutions for stainless steel, we offer the flexibility to choose from the following crystal structures:

- Ferritic stainless steel: Known for its magnetic properties and superior thermal conductivity when compared to austenitic stainless steel.

- Austenitic stainless steel: Exhibiting high malleability and resistance to work hardening, austenitic stainless steel is non-magnetic in stress-relieved condition.

- Martensitic stainless steel: This stainless steel type is prized for its hardness and strength, forming by rapid cooling of austenite. It excels in applications needing exceptional wear resistance but may not be suited for high toughness or ductility requirements.

- Duplex stainless steel: Combining equal parts austenitic and ferritic structures, it offers high strength, exceptional corrosion resistance, and excellent weldability.

Related Resources

CNC Machining Guide

Four main methods for polishing acrylic (PMMA)