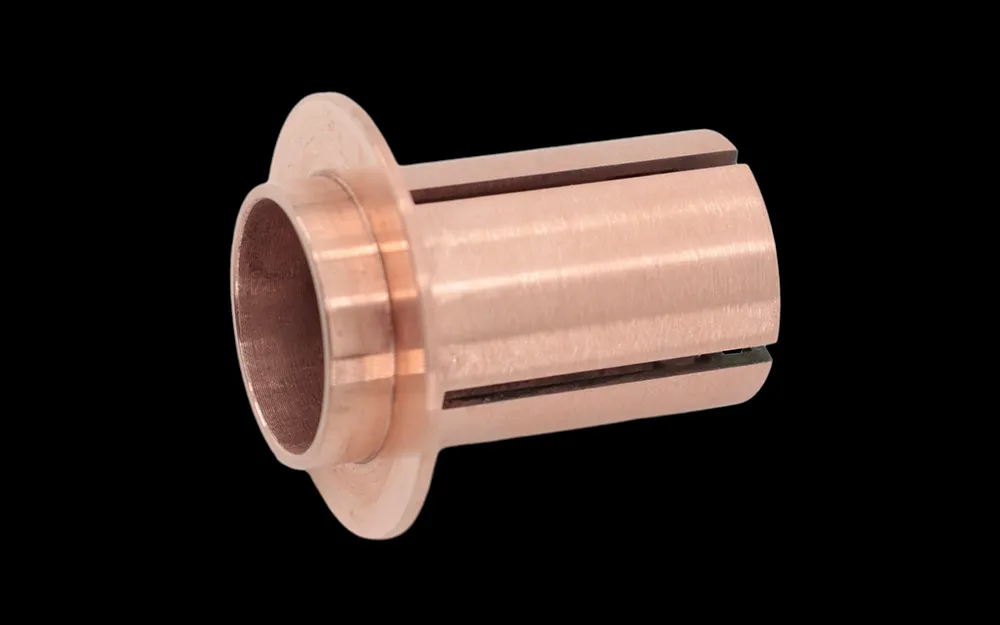

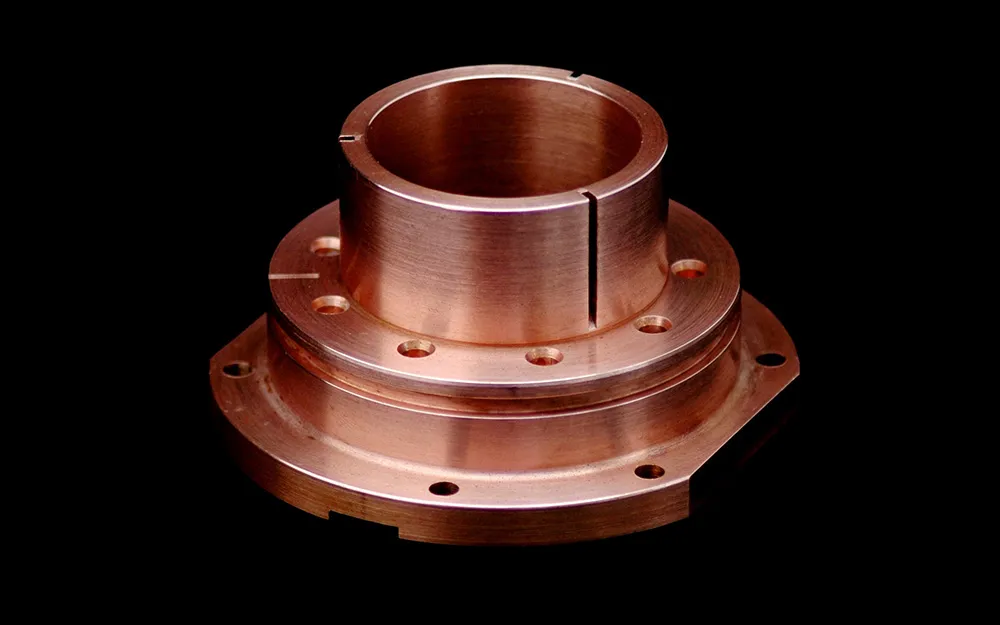

Copper for CNC machining

Copper is a highly versatile and durable material with many useful benefits, including:

- Corrosion resistance

- Superior recyclability

- Exceptional thermal conductivity (electrical connectors, circuit boards)

- Aesthetic versatility (decorative objects)

Available grades

CNC copper machining involves using different grades of alloys, each with specific properties and advantages.

Description

This grade is composed of 99.9% of copper. Also called “red copper”, it is the most common form of copper and is universal for electrical applications. It is known for its very high electrical and thermal conductivity and excellent formability properties.

Applications

Electrical

Description

C101 offers higher conductivity due to its purity (99.99% copper). 110 is generally easier to machine and thus more cost-effective.

Applications

Electrical

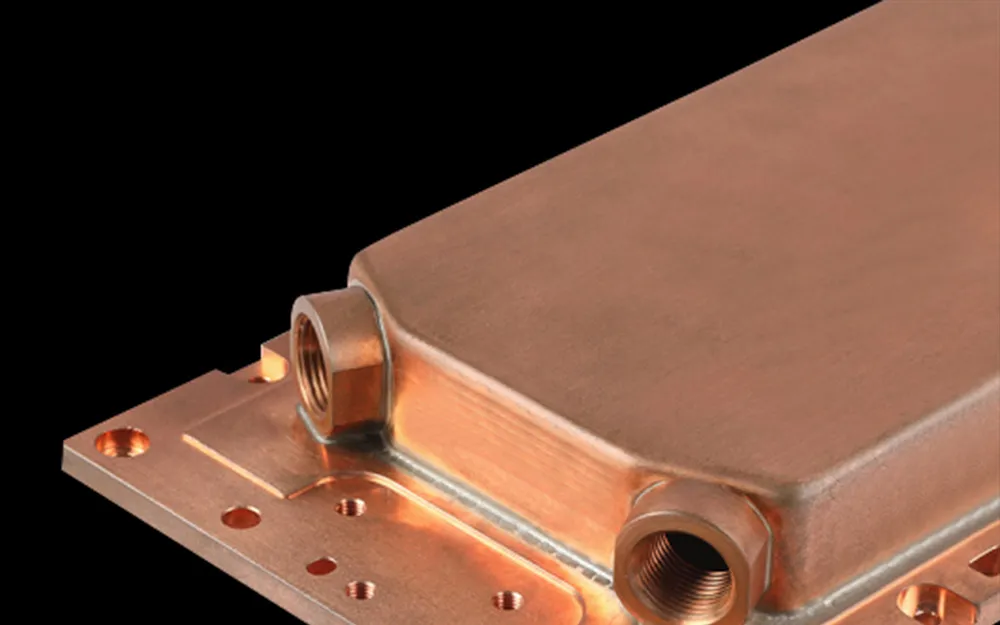

Industries using CNC machined copper components

Copper is commonly used for a wide range of products and parts. Our competencies and capabilities in copper make Protolis the ideal partner for numerous applications in various industries:

- For pipes, fittings, and valves in plumbing

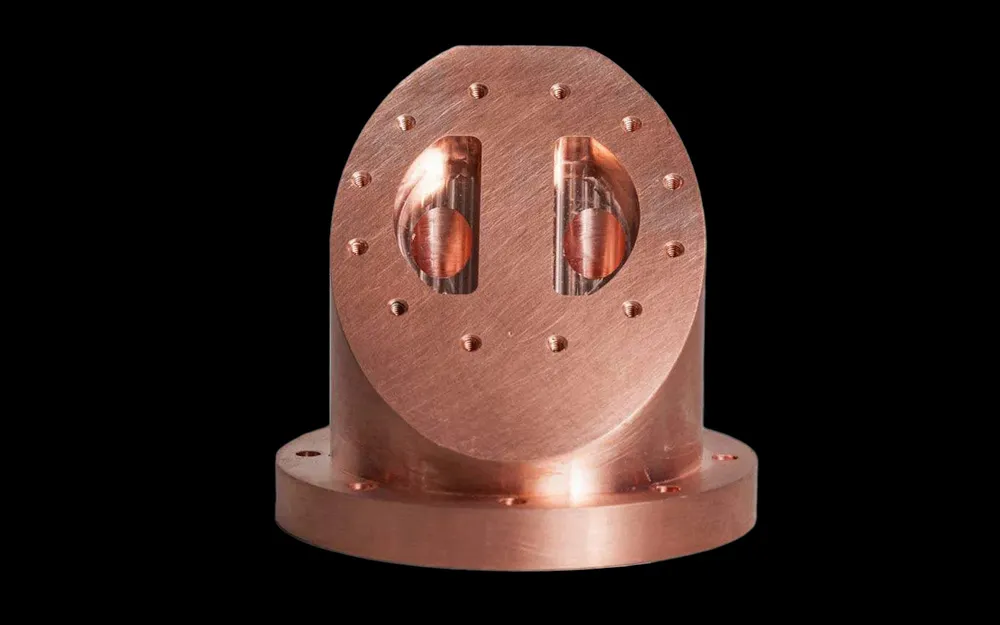

- Electrical components such as wiring, connectors, and circuit boards

- For heat exchangers in various industries, including automotive, construction, and housing

- For decorative objects such as sculptures, jewelry, and home decor

Industries using CNC machined copper components

Our finishes for copper

Our selection of CNC machined copper parts comes with a variety of finishing options, such as powder coating, polishing, brushing, and sandblasting.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

Powder coating is similar to liquid spray paint, except that this process uses a dry powder. It improves the resistance to wear and corrosion. The resulting surface is uniform.

This polishing generally involves changing the level of roughness of a surface by various manual, mechanical, or chemical techniques. This can change the dimensional or geometric accuracy of the part.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

Brushing is a surface finishing method that forms continuous paralleled lines on the surface of metal parts. The purpose is usually to obtain a decorative effect with a slight level of reflection.

Sand blasting is the high-pressure projection of silica sand on the surface of the workpiece to create a matte surface, including creating aesthetic consistency for plastic and metallic parts.

Applications

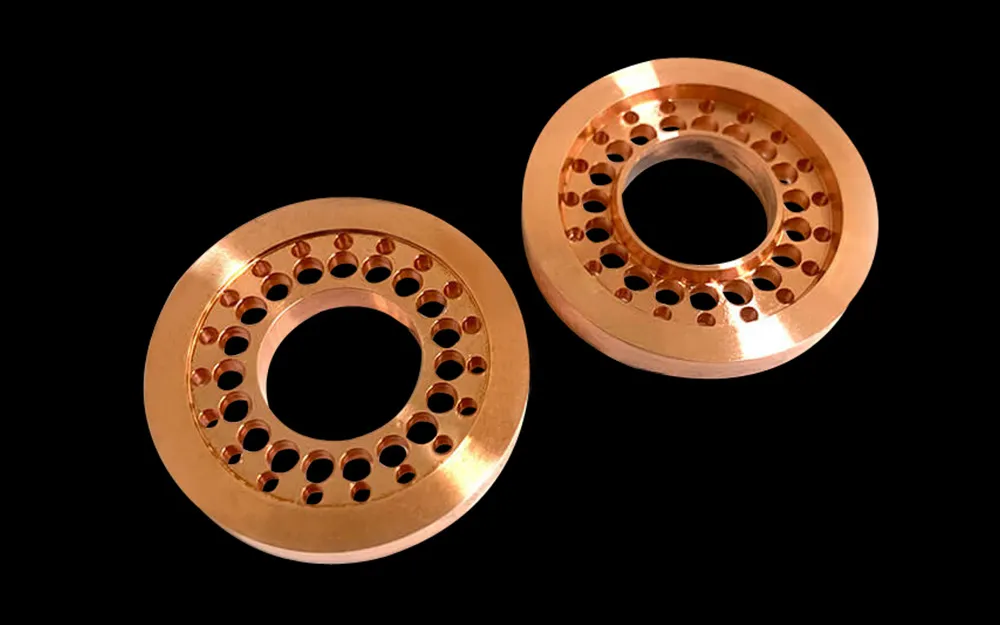

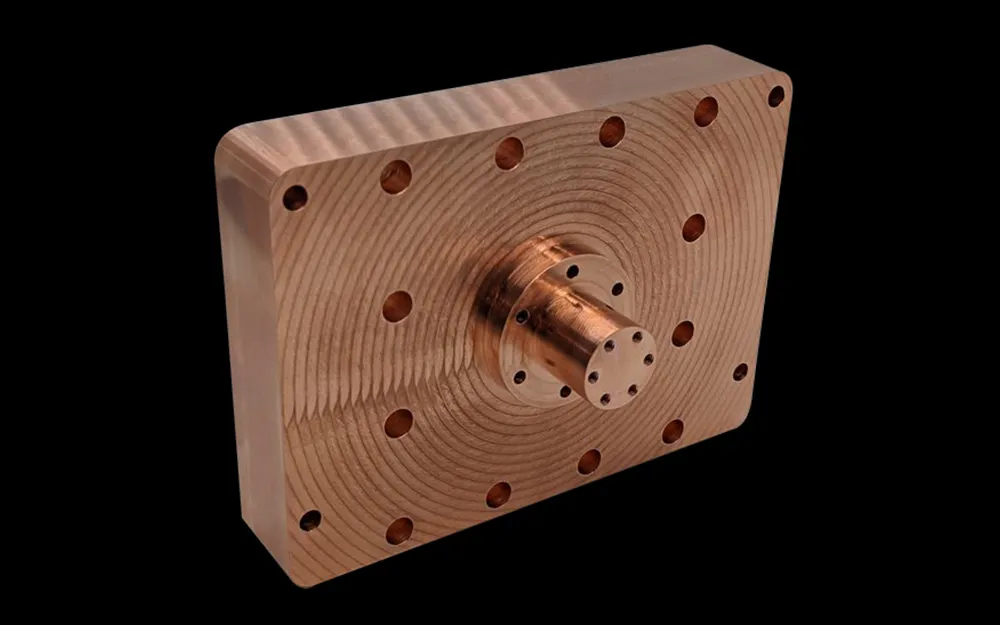

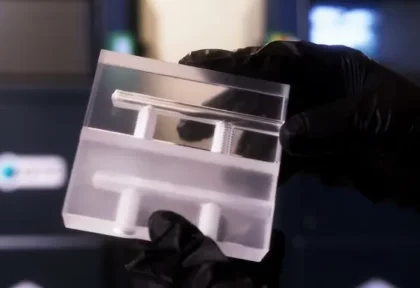

Explore the versatility of copper in CNC machining for prototyping and small series production projects.

Our CNC copper characteristics

Your project in 5 steps

Need to get your copper prototype or production parts in no time? Here’s what to expect when you work with Protolis, a flexible organization that always provides personalized service and solutions.

Your Quote

Upload files and specifications

DFM

Design optimization

Production

Close follow-up

Quality Control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

CNC machining copper FAQs

What grades of copper can be machined?

A wide range of copper can be CNC machined. At Protolis, we can provide copper 101 and 110, which are frequently utilized grades. C101 has higher purity than C110 but is less machinable. Compared to C101, C110 provides enhanced machinability and electrical conductivity, making it more suitable for crafting machined parts such as busbars in electrical setups. C101 is typically reserved for crafting crucial components demanding optimal efficiency. Given C101’s ease of machining, it’s ideal for fabricating intricate and minute copper parts. For turning tasks, C110 is the preferred choice due to its superior ductility over C101.

Does copper have good corrosion resistance?

Yes, copper possesses good corrosion resistance. It naturally forms a protective oxide layer on its surface when exposed to the atmosphere. This layer, often a greenish patina, acts as a barrier and prevents further corrosion of the underlying metal. Additionally, copper is resistant to many natural elements and environments. For example, it doesn’t corrode from exposure to water (even salt water), making it a popular choice for plumbing, marine, and similar applications. However, in specific environments with certain chemicals or compounds, such as ammoniacal solutions, copper might show some susceptibility to corrosion. It’s always important to consider the specific environmental conditions when evaluating the suitability of copper or any other material.

Should I use copper or brass for my CNC parts?

Copper offers better flexibility, ductility and conductivity, while brass offer greater machinability and better corrosion resistance in saltwater and sea environments. Its durability and hardness also enable it to withstand higher stress applications. If the color matters in your project, copper has a distinctive reddish-brown color and brass has a famous brighter yellowish-gold appearance making it often used for decorative purposes

Related Resources

CNC Machining Guide

Four main methods for polishing acrylic (PMMA)