Brass for CNC Machining

This alloy composed of copper and zinc has many benefits that make it an ideal choice for various applications:

- Excellent electrical conductivity

- Low friction capabilities

- Durable and corrosion-resistant

Available Grade

CNC brass machining involves using a specific grade of alloy with distinct properties and advantages.

Description

This is one of the most used brass alloy (copper plus zinc) and known as architectural bronze. It is an alpha/beta (37-45% Zinc) alloy that is very well suited for machining.

Applications

Architectural

Benefits of Brass for CNC Machining

Brass machining is commonly used for a wide range of products and parts, including:

- Automotive: Valves, fittings, connectors, and electrical components

- Electronics: Electrical connectors, terminals, switches, and more

- Plumbing: Fittings, valves, and connectors

- Aerospace: Aircraft components including fittings, connectors, and hydraulic parts

- Medical: Instruments and equipment

- Military: Ammunition casings, bullet jackets, and more

- Marine: Valves, pumps, and fittings

Benefits of Brass for CNC Machining

Our Finishes for Brass

Our selection of CNC machined metal brass parts comes with a variety of finishing options, such as fine polishing, brushing, and sandblasting.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

This polishing generally involves changing the level of roughness of a surface by various manual, mechanical, or chemical techniques. This can change the dimensional or geometric accuracy of the part.

Brushing is a surface finishing method that forms continuous paralleled lines on the surface of metal parts. The purpose is usually to obtain a decorative effect with a slight level of reflection.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

Powder coating is similar to liquid spray paint, except that this process uses a dry powder. It improves the resistance to wear and corrosion. The resulting surface is uniform.

Sand blasting is the high-pressure projection of silica sand on the surface of the workpiece to create a matte surface, including creating aesthetic consistency for plastic and metallic parts.

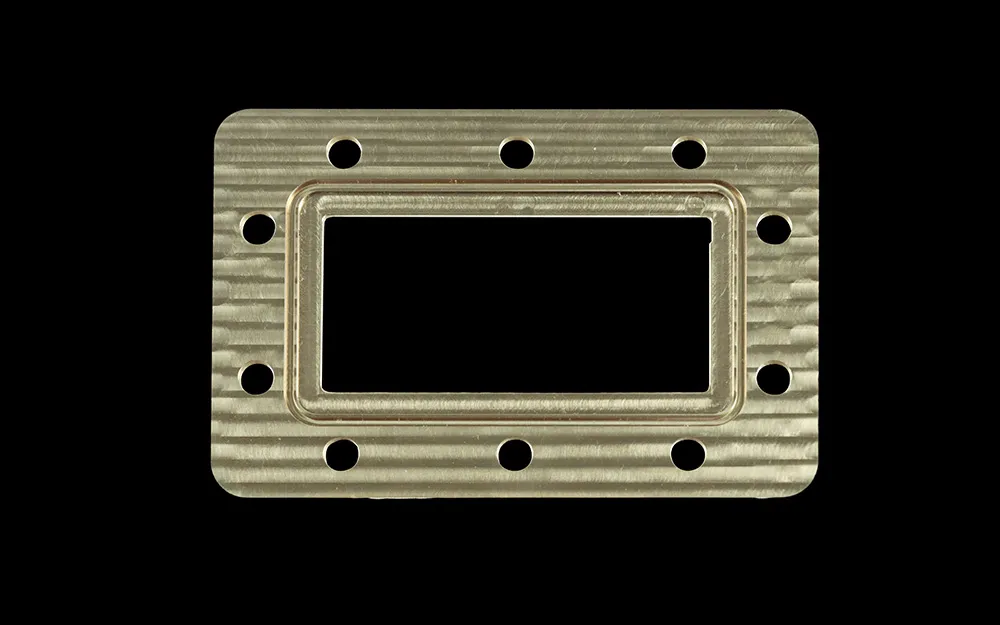

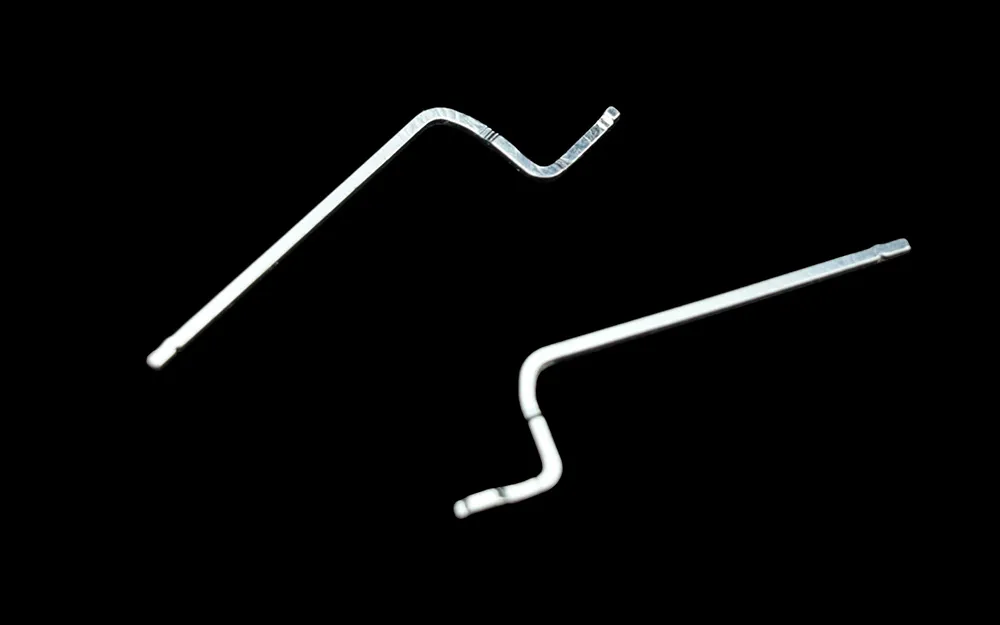

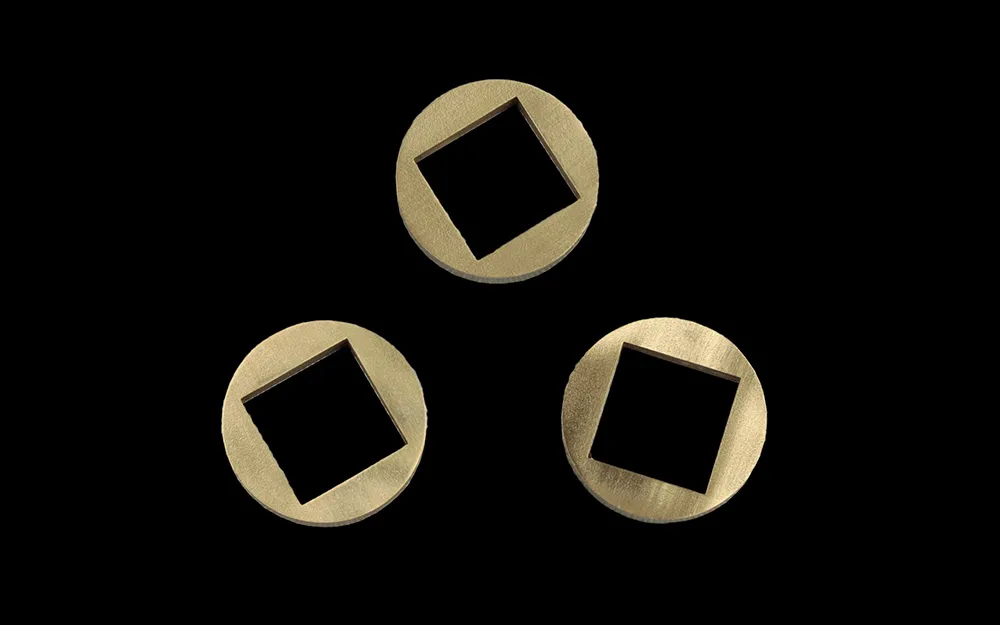

Applications

Explore the versatility of brass in CNC machining for prototyping and small series production projects.

Our CNC Brass Characteristics

Your project in 5 steps

Work with Protolis to get your brass prototype or production parts without delay—and a personal response each and every time. Here’s how it works.

Your Quote

Upload files and specifications

DFM

Design optimization

Production

Close follow-up

Quality Control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

CNC Machining Brass FAQs

Which brass alloy is best for machining?

The choice of the best brass alloy for machining will depend on your specific machining requirements and the desired characteristics of the finished parts. The free-cutting brass C360, also known as C36000 brass, is one of the most popular brass alloys for machining. It contains a high percentage of copper (about 61.5%) and small amounts of lead (about 3.7%), which enhance its machinability. The lead acts as a lubricant, reducing tool wear and producing clean, well-defined chips. This alloy is commonly used for components like screws, fittings, and fasteners.

Is brass expensive to CNC machine?

Brass tends to be more expensive to CNC machine compared to metals like aluminum and mild steel due to its higher material cost (it’s an alloy of copper and zinc), potential tool wear, longer machining times, and additional finishing requirements if the applications require a high-quality surface finish. However, its unique properties and aesthetic appeal make it a valuable choice for certain applications.

How much does it cost to CNC brass?

The cost of CNC machining brass is determined by several factors, including the complexity and size of the part and the specific type of brass used. These variables impact the type of machining equipment needed, the production time required, and the cost of the raw material.

Brass is typically more expensive than aluminum and it is generally less expensive than stainless steel and specialty alloys when it comes to CNC machining costs.

Related Resources

Extrusion Guide

Racing car bodywork for one of the world’s premier auto shows