Aluminum for CNC Machining

CNC aluminium machining offers numerous benefits that make it an ideal choice for various applications:

- Excellent machinability and ductility

- Favorable strength-to-weight ratio

- High thermal and electrical conductivity

- Inherent resistance to corrosion

Available Grades

CNC aluminum machining involves using different grades of aluminum alloys, each with specific properties and advantages.

Description

It is part of the 2000-series aluminum alloy with the addition of copper, known as a “hard” alloy. Compared to others, the copper provides substantial increases in strength but reduces ductility and corrosion resistance.

Applications

Transportation (general structural components)

Automotive

Aerospace

Defense

Description

Magnesium is the main element used in the composition of the 5000 series. Grade 5083 has the highest strength of the non heat treatable alloys, although it is not as strong or as hard as the grade 6082. It has excellent resistance to both chemical and atmospheric attack, performing particularly well in sea water/salt water and is often referred to as a marine grade of aluminum.

Applications

Transportation

Defense

Storage tanks

Marine

Description

This is an alloy in the wrought aluminum-magnesium-silicon family that offers medium mechanical properties, high corrosion resistance, and good aptitude for decorative anodizing.

Applications

Food industry

Construction (doors, windows, facades, winter gardens)

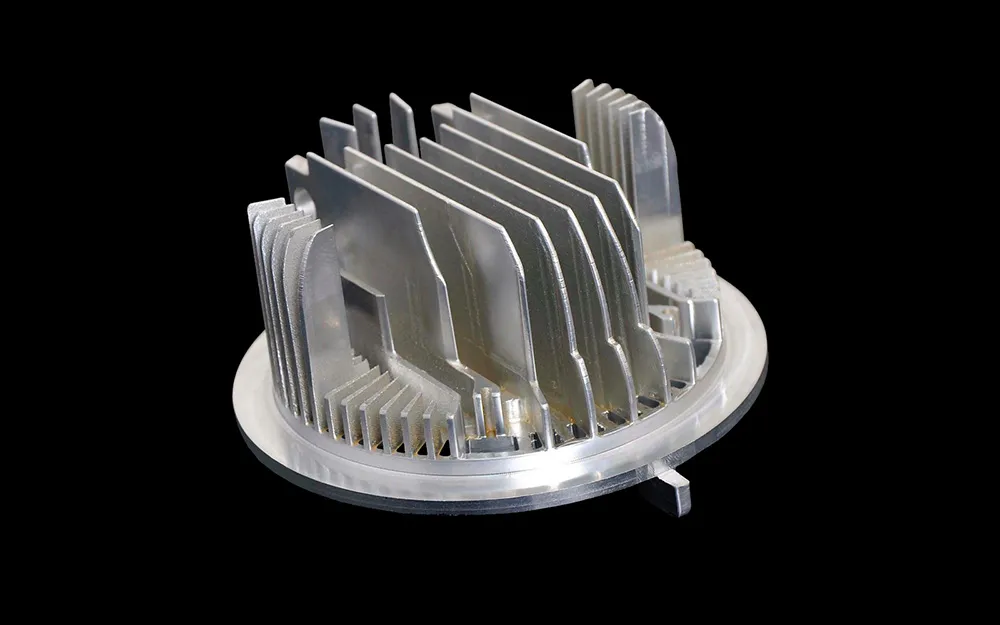

Electronic components (heat dissipating elements)

Automotive parts

Furniture and office equipment

Description

This is the most popular aluminum alloy containing magnesium and silicon. The alloy is appreciated because of its versatile performance and all-around mechanical properties. It shows excellent machinability and natural corrosion resistance.

Applications

Transport

Marine industry

Aerospace

Architectural decoration

Description

This is a medium strength alloy commonly known as an architectural alloy. It has a high corrosion resistance, suitable for welding, and can be easily anodised. It features medium mechanical properties (lowest tensile strength among the 6000-series) with good surface finish.

Applications

Architectural (trims, framework, brackets, structural supports)

Automobile

Agriculture (conduit, pipe and tube for irrigation systems)

Home goods (furniture, recreational equipment)

Construction (pipes, tubing, stair rails, windows, door frames, roofs, signage)

Description

This alloy is very similar to 6061 with a slightly better tensile strength (due to the addition of manganese). It has the highest tensile strength among the 6000-series with excellent corrosion resistance (certified for use in marine application).

Applications

Construction (bridges, roof trusses, structural profiles, seamless tubes)

Highly stressed applications (trusses, bridges, cranes, ore skips)

Kitchen (beer barrels, milk churns)

Description

Known as the zinc grades (zinc being the largest alloying element), the 7000 series grades are the hardest and strongest grades of aluminum. Grade 7075 is the most common of this series. It is a very high strength alloy; the strongest of all commercial grades of aluminum (stronger than many types of mild steel).

Applications

Aerospace

Defence

Transportation

Description

Part of the 1000 series, which has a minimum of 99% aluminum with no major alloying additions. The 1050 is known for its excellent corrosion resistance, high ductility, high electrical conductivity, and low mechanical resistance. This grade is suitable for applications where moderate strength and good malleability are required.

Applications

Chemical industries

Construction (facades, roofing)

Interior decoration

Electrical/electronic (housing of devices)

Automotive (interior trim, heat shields)

Description

This grade is one of the higher strength non-heat treatable alloys. It benefits from a medium to high fatigue strength, making the product an excellent choice for use in structures exposed to excessive vibrations. 5052 also offers improved corrosion resistance, especially in marine atmospheres. It offers good weldability and formability.

Applications

Marine

Food industry

Chemical industry

Benefits of Aluminum for CNC Machining

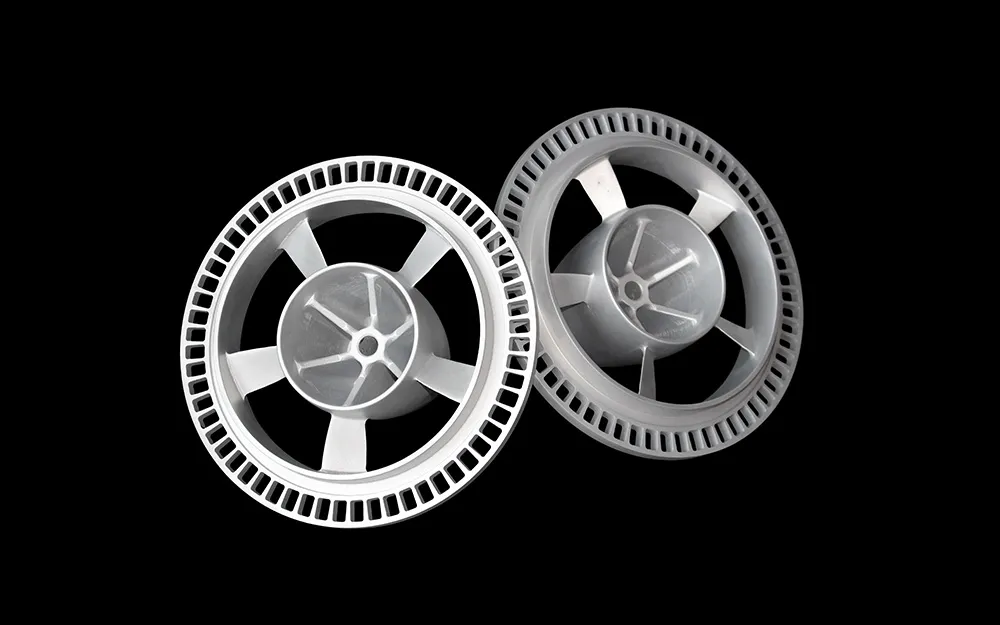

With its lightweight nature, machinability, and impressive strength-to-weight ratio, aluminum excels across diverse applications:

- Aerospace: Offers weight efficiency, strength, and durability in parts

- Automotive: Drives high-performance components

- Electronics: Precise for computer parts and circuitry

- Medical: Shapes surgical instruments and prosthetics

- Machinery: Powers pumps, valves, and compressors

Benefits of Aluminum for CNC Machining

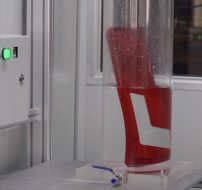

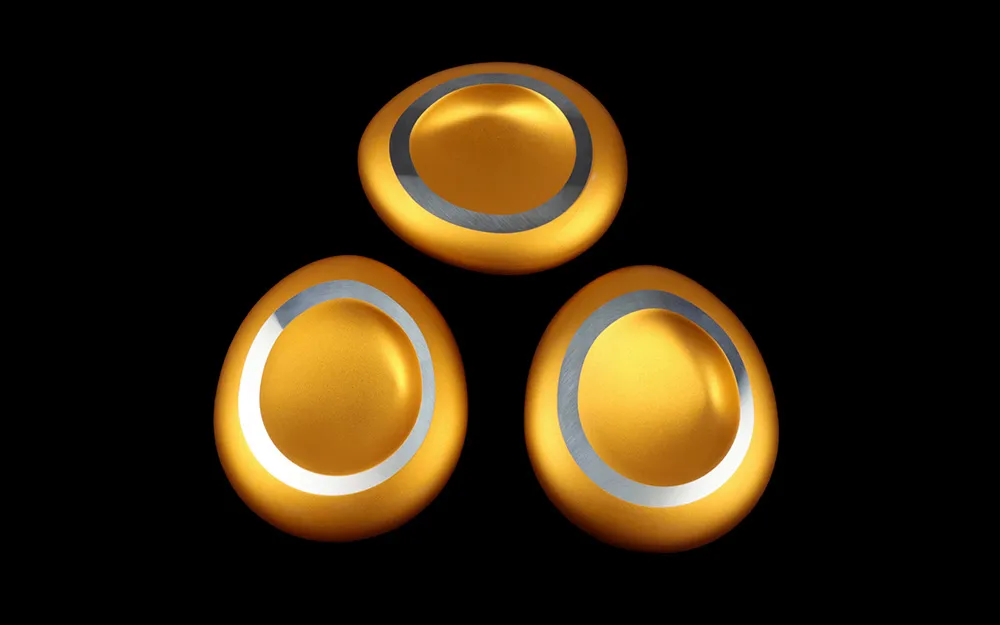

Our Finishes for Aluminum

Our selection of CNC machined aluminum parts comes with a variety of finishing options, such as anodizing, powder coating, polishing, brushing, and sandblasting.

The type 2 and type 3 processes we provide are chemical (electrolyte) processes based on sulphuric acid that create an oxide layer. They protect parts from corrosion, increase their durability, and make the parts dielectric and non-conductive.

This polishing generally involves changing the level of roughness of a surface by various manual, mechanical, or chemical techniques. This can change the dimensional or geometric accuracy of the part.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

Brushing is a surface finishing method that forms continuous paralleled lines on the surface of metal parts. The purpose is usually to obtain a decorative effect with a slight level of reflection.

Powder coating is similar to liquid spray paint, except that this process uses a dry powder. It improves the resistance to wear and corrosion. The resulting surface is uniform.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

Our CNC Aluminum Characteristics

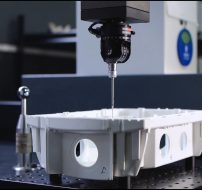

Your project in 5 steps

When you work with a flexible organization that provides a personal response to your needs without any setback, you can expect to receive your CNC aluminium prototypes or production parts in no time.

Your Quote

Upload files and specifications

DFM

Design optimization

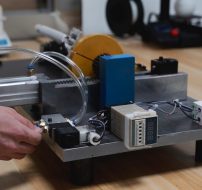

Production

Close follow-up

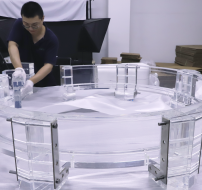

Quality Control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

CNC Machining Aluminum FAQs

What is the best aluminium for CNC machining?

The choice of aluminum alloy for CNC machining should indeed align with the specific requirements of your project. One of the highly favored aluminum alloys in the industry, commonly chosen for CNC machining, is 6061-T6. The 6061-T6 aluminum alloy is frequently chosen for CNC machining due to its versatility, ease of machining, heat treatability, and a balance of mechanical properties:

- Versatility: 6061-T6 is known for its versatility, making it suitable for a wide range of applications. Its versatility stems from its balanced combination of properties.

- Ease of machining: This alloy is easy to machine, making it a preferred choice for CNC machining. Its machinability allows for efficient production of precision components.

- Heat treatability: 6061-T6 can undergo various heat treatments to enhance its mechanical properties, offering flexibility in achieving the desired material characteristics for specific applications.

- Mechanical properties: While not suitable for high-stress applications due to its relatively modest ultimate tensile strength (310 MPa), it offers reasonable elongation at break (17%), a moderate modulus of elasticity (68.9 GPa), and a hardness of 60 HRB.

However, it’s important to note that the choice of aluminum alloy should consider factors like mechanical strength, corrosion resistance, weight, and thermal conductivity based on the specific needs of your project.

Is aluminum good for medical applications?

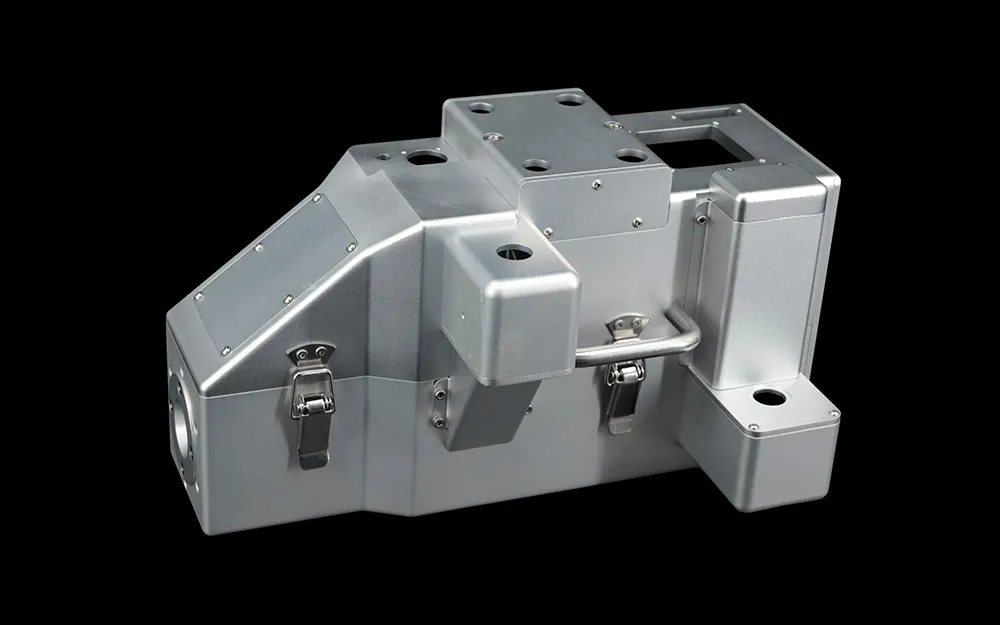

Aluminum is not commonly used for direct medical applications involving implantable or contact with bodily fluids, but it does have some medical and healthcare-related uses in equipment and devices like such as diagnostic instruments, surgical instruments, bed frames, and patient monitoring devices. Its lightweight and corrosion-resistant properties make it suitable for these applications. Aluminum is also often used in the construction of medical transport containers, such as cases for carrying delicate medical equipment and pharmaceuticals. For implantable applications, materials like titanium, stainless steel, and certain biocompatible alloys are preferred.

Are aluminum parts and prototypes strong?

The strength of aluminum prototypes depends on several factors, including the alloy used, the manufacturing method, post-processing treatments, and the design of the prototype itself. Here’s a breakdown of the factors affecting the strength of aluminum prototypes:

- Aluminum alloy: Not all aluminum alloys have the same mechanical properties. Some aluminum alloys are inherently stronger than others. For example: 6061-T6 is a commonly used aluminum alloy for prototyping and has good strength-to-weight ratio and corrosion resistance. 7075-T6 is another alloy known for its high strength, making it suitable for applications where maximum strength is crucial.

- Manufacturing method:

- CNC machining: Prototypes made using CNC machining are usually strong, as the process does not introduce internal stresses or voids. The material is consistent throughout the prototype.

- Casting (e.g. die casting, sand casting): While casting can produce strong parts, there’s a risk of porosity (tiny voids) inside the aluminum casted part, which can reduce its overall strength.

- 3D printing (DMLS): Direct metal laser sintering can create detailed and complex prototypes, but the mechanical properties may differ from bulk material.

- Heat treatment and post-processing: Aluminum can be heat-treated to improve its mechanical properties. For instance, the “T6” in “6061-T6” indicates a specific type of heat treatment. Properly heat-treated aluminum can significantly enhance its strength. Moreover, processes like shot peening or surface hardening can improve wear resistance and reduce surface-related weaknesses.

The strength of the final part or prototype will therefore be a combination of these factors. It’s also important to consider that while aluminum is generally less strong than steel, its high strength-to-weight ratio makes it an excellent choice for applications where weight is a critical factor, such as in the automotive and aerospace industries.

Related Resources

Extrusion Guide

Racing car bodywork for one of the world’s premier auto shows