Metals for CNC manufacturing

In CNC production, selecting metal parts is a typical choice for small-scale series and prototyping projects. Protolis provides a comprehensive selection of grades, each tailored to offer distinct advantages.

- Extensive inventory: More than 25 grades available in stock

- High level of control and traceability: Plus our commitment to maintaining the highest standards

- Specific grades on demand: We understand that your projects may require specific grades that aren’t readily available

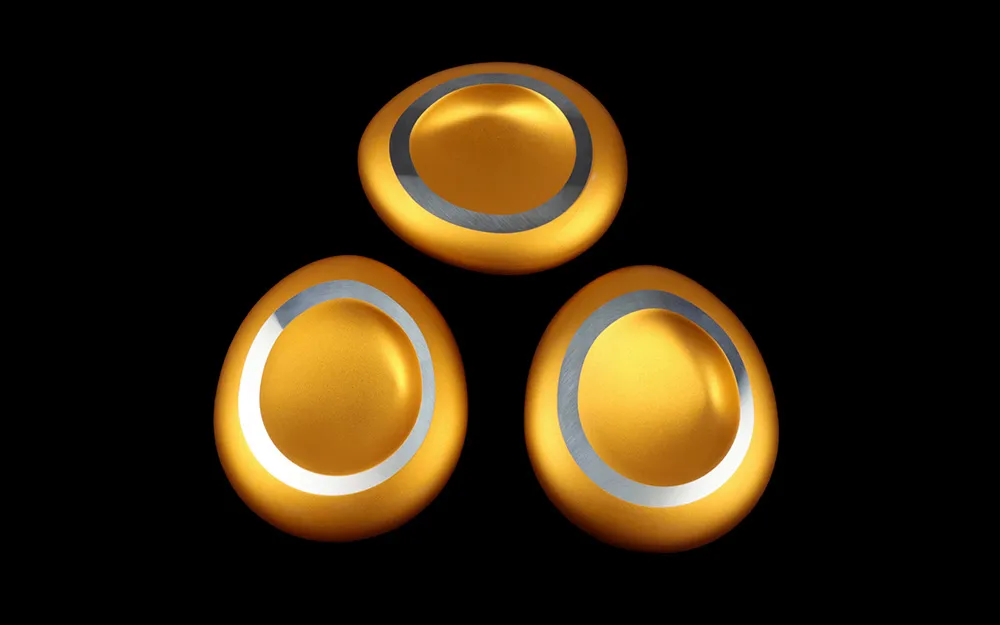

Common CNC metals

Discover the possibilities of metal materials for CNC machining.

Description

With its lightweight nature, machinability, and impressive strength-to-weight ratio, aluminum excels across diverse applications.

Applications

Aerospace: Offers weight efficiency, strength, and durability in parts.

Automotive: Drives high-performance components.

Electronics: Precise for computer parts and circuitry.

Medical: Shapes surgical instruments and prosthetics.

Machinery: Powers pumps, valves, and compressors.

Description

This alloy composed of copper and zing has many benefits that make it an ideal choice for various applications.

Applications

Automotive: Valves, fittings, connectors, and electrical components.

Electronics: Electrical connectors, terminals, switches, and more.

Plumbing: Fittings, valves, and connectors.

Aerospace: Aircraft components including fittings, connectors, and hydraulic parts.

Medical: Instruments and equipment.

Military: Ammunition casings, bullet jackets, and more.

Marine: Valves, pumps, and fittings.

Description

Stainless steel is particularly suitable for use in applications that involve exposure to harsh or corrosive environments.

Applications

Culinary uses: widely used for cutlery, kitchen utensils, and cookware due to its corrosion resistance, hygiene, and durability.

Kitchen sinks: for their durability, resistance to stains, and ease of cleaning.

Marine: Essential in the marine sector, where exposure to saltwater and harsh environmental conditions is common.

Surgical tools and medical equipment: indispensable in the healthcare sector for its biocompatibility, resistance to corrosion from sterilization processes, and ease of cleaning.

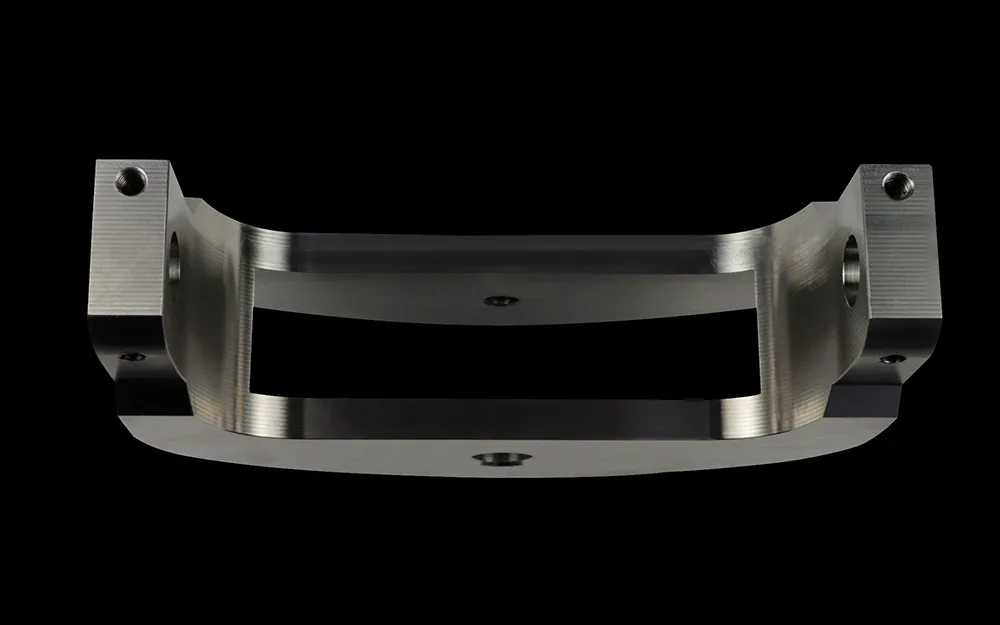

Description

Steel properties vary according to the composition of carbon and some alloying elements.

Applications

In automotive, for engine components and suspension parts.

Structural components for aerospace.

Beams, columns, and other structural components in construction

Pumps, valves, and gears in Industrial machinery.

For surgical instruments, implants, and other medical devices.

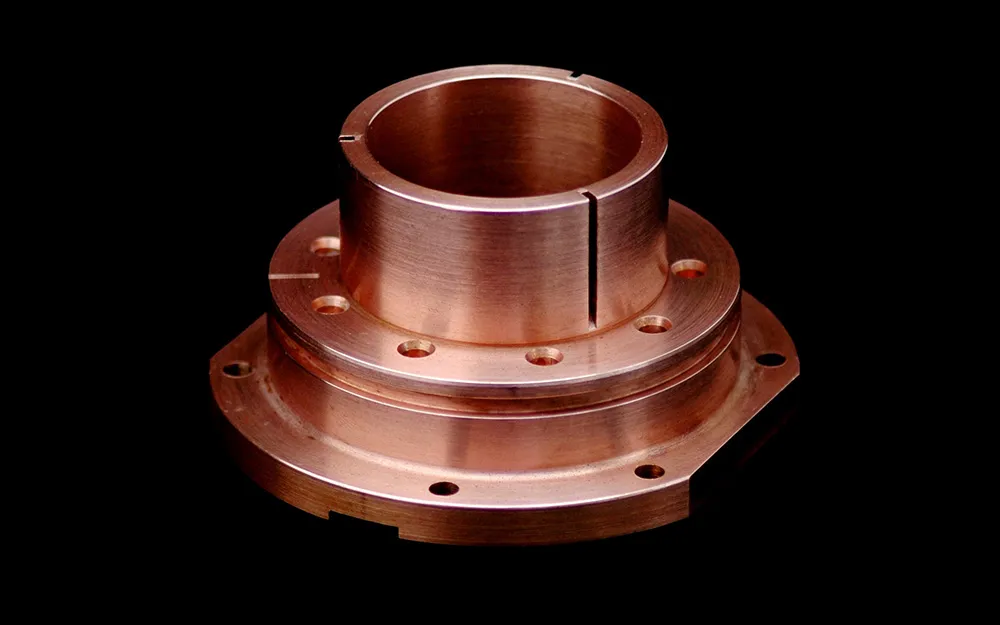

Description

Copper is a highly versatile and durable material that has many electrical applications.

Applications

For pipes, fittings, and valves in Plumbing.

Electrical components such as wiring, connectors, and circuit boards.

For heat exchangers in various industries, including automotive, construction and housing.

For decorative objects such as sculptures, jewelry, and home decor.

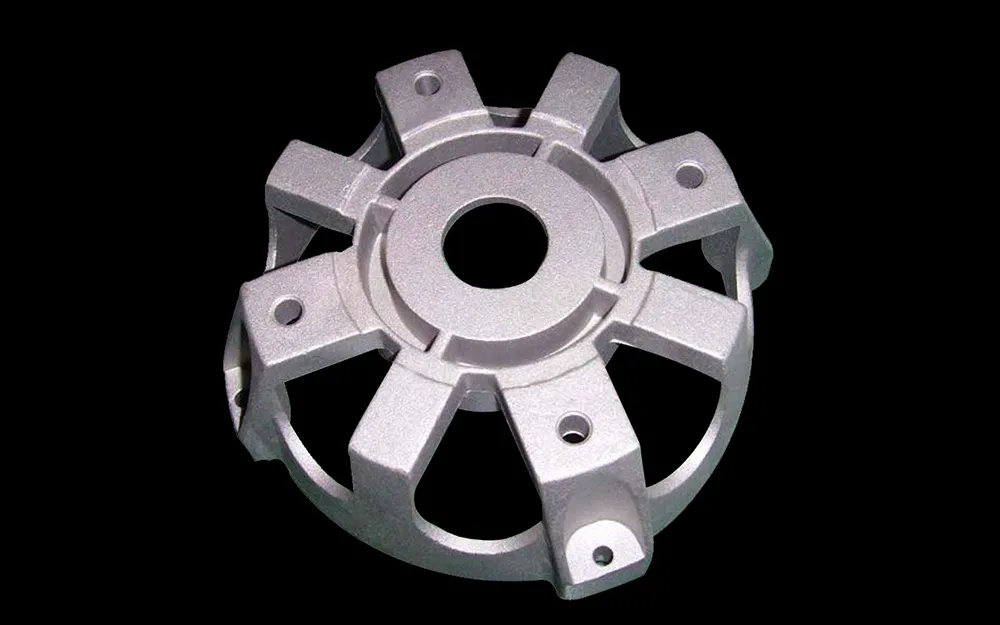

Description

Zamak is zinc-based alloys generally composed of a blend of zinc, aluminum, magnesium, and copper.

Applications

In automotive, for gears, brackets, and electrical connectors.

In medical, for surgical instruments and orthopedic implants.

In aerospace, for fasteners, brackets, and housings.

In consumer goods, for door handles, locks, and decorative items.

In electrical and electronics, for switches, connectors, and housings.

CNC metal machining services

Metal machining using CNC is a sophisticated process that involves the utilization of computer-controlled machinery to achieve precise and intricate shapes from metal workpieces. CNC metal cutting, in particular, is a highly accurate manufacturing procedure wherein material is systematically eliminated from a solid metal workpiece to attain the intended form or configuration.

At Protolis, we boast an extensive array of cutting-edge machinery that is custom-tailored to accommodate your distinct requirements. Our comprehensive equipment lineup encompasses CNC milling, CNC drilling, CNC turning, and the advanced capabilities of CNC 3-axis and 5-axis machining. This enables us to cater to a wide spectrum of manufacturing demands while upholding the highest standards of precision and quality.

CNC metal machining services

Our finishes for CNC metals machining

Our selection of CNC machined metal parts comes with a variety of finishing options. Select your preferred finishing option for enhanced functionality and aesthetics.

The type 2 and type 3 processes we provide are chemical (electrolyte) processes based on sulphuric acid that create an oxide layer. They protect parts from corrosion, increase their durability, and make the parts dielectric and non-conductive.

Powder coating is similar to liquid spray paint, except that this process uses a dry powder. It improves the resistance to wear and corrosion. The resulting surface is uniform.

This oxide-based surface treatment is applicable on ferrous metals to reduce light reflection and slightly increase corrosion and friction resistance. It gives a smooth appearance and black color. It resists bending and does not alter magnetic properties.

These processes involve the deposition of a thin layer of zinc on a metal surface in order to improve its resistance to rust.

A paint finish that enhances the surface condition both functionally and aesthetically. It is possible to achieve different effects of appearance: satin, matte, gloss, or semi-gloss.

This type of finishing is a high-level polishing, also known as mirror polishing, that gives the part a smooth, reflective, and aesthetically pleasing appearance.

To learn more about these finishing options, please refer to our finishing page here.

Applications

Explore the versatility of metal CNC machining for prototyping and small series production projects.

Our CNC metals characteristics

Your project in 5 steps

Get your prototypes and production parts in no time with Protolis. Here’s how our client projects typically work.

Your quote

Upload files and specifications

DFM

Design optimization

Production

Close follow-up

Quality control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

Metal CNC machining FAQs

What metals can be CNC machined?

CNC machining is a versatile process that can be applied to a wide range of metals. At Protolis, we offer a comprehensive selection of metals for CNC machining, including aluminum, steel, stainless steel, and brass, among others. However, it’s important to be aware of two key limitations when working with metals in CNC machining:

- Hardness: The hardness of a material can significantly impact its machinability. Harder metals, such as titanium, can pose challenges during machining. Specialized tools and techniques may be required to achieve precise results when working with these materials.

- Reactive metals: Reactive metals such as magnesium, sodium, and potassium are highly dangerous to machine using conventional CNC processes due to their extreme reactivity with air and water. Specialized equipment and strict safety measures are vital to ensure both team safety and successful machining.

Are CNC metal parts strong?

CNC-machined metal parts can be very strong, but the strength of the final product depends on several factors, including the choice of metal material, the machining process, and the design of the part itself. Here are some key factors that influence the strength of CNC-machined metal parts.

- Material selection: The choice of metal material plays a critical role in determining its strength. Different metals have varying levels of strength, hardness, and other mechanical properties. Common structural metals like steel, aluminum, and titanium exhibit different strength characteristics. For example, titanium is known for its exceptional strength-to-weight ratio, making it a strong choice for many applications.

- Heat treatment: Many metals can be heat-treated to improve their strength. Heat treatment processes, such as quenching and tempering, can significantly increase the hardness and strength of certain metals. This post-processing step can enhance the overall strength of CNC-machined components.

In summary, CNC machining is a valuable tool for creating precise components from various metals, but it doesn’t inherently alter the strength of the metal itself. The strength of a CNC-machined metal part depends on factors such as material selection, inherent properties, and any post-processing treatments applied. So, yes, CNC machining can be used to produce parts with extremely strong metals like titanium, but the strength primarily derives from the chosen material and any subsequent treatments.

Which material has best machinability?

Among the commonly used metals for CNC machining, soft metals like brass, copper, and aluminum are known for their excellent machinability. Aluminum is known for its ease of workability, which is one of the reasons why it’s one of the most commonly used metals for CNC machining. It is lightweight, corrosion-resistant, and has good mechanical properties, making it a versatile choice.

In addition to these soft metals, there are also specific types of steel known as “free-machining steel”. These steels are engineered for improved machinability and contain additional elements like sulfur and lead. These elements aid in chip formation and reduce tool wear, making machining easier and more efficient.

Related resources

Extrusion Guide

Racing car bodywork for one of the world’s premier auto shows