Assembly and fitting

It can be extremely challenging to design individual parts on your computer and achieve a final assembled product that incorporates multiple materials, technologies, and finishes—all of which need to fit together seamlessly. Protolis makes it simple with an integrated service that includes both manufacturing and assembly, effectively bringing your designs to life as fully functional products.

Our assembly skills at every stage of the project

Step 1: DFM

Prior to commencing production, we will conduct a Design for Manufacturing (DFM) analysis on your drawings as part of our project process. Our skilled team will utilize their expertise in assessing tolerances and potential deformation, as well as their extensive experience with various raw materials, finishes, and processes. This analysis enables us to provide recommendations for optimizations, such as addressing gaps between parts, shape interference, and more.

Step 1: DFM

Step 2: Integration of other components

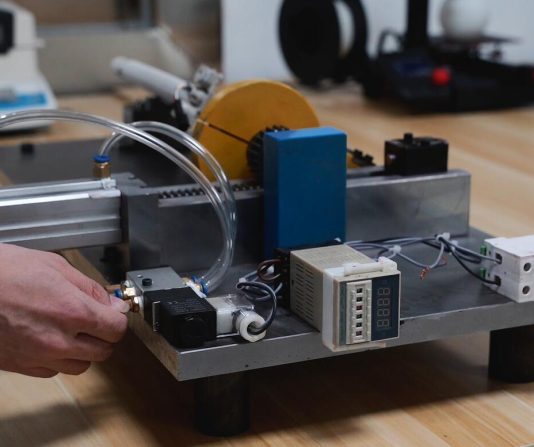

We have the capability to incorporate additional components into our assemblies. Through our audited network of suppliers, we can source standard and custom components that are beyond our in-house manufacturing capabilities, such as hinges, springs, bolts and screws, rods, circlips, cables, metal inserts, O-rings, and more.

You also have the flexibility to provide us with your own electrical components, such as PCBs for electro-mechanical assemblies, or any other sourced components you may have.

Step 2: Integration of other components

Step 3: Assembly and final adjustments

After obtaining all the necessary components, our finishing department will meticulously carry out rework on specific areas, carefully removing any excess material and eliminating irregularities to ensure a perfect fit for all the parts. Some operations of assembling, such as welding or riveting, can be done at this stage. This precision work is conducted by our experienced team, who possess the expertise to deliver exceptional results.

Step 3: Assembly and final adjustments

Step 4: Final inspections

To conclude the process, we will conduct a thorough inspection of the final product, drawing upon our expertise and the information provided to us. Additionally, we offer the option to arrange a video call with our customers, enabling us to demonstrate the proper functionality of the final assembly and validate the project before exporting. We remain flexible and open to implementing minor modifications or optimizations, if required, to ensure your satisfaction.

Step 4: Final inspections

Assembly to fit your project’s needs

In addition to our 15+ years of experience in prototyping projects and low-volume production, the true advantage of collaborating with Protolis lies in our expertise in final product assembly—and the strong bond we foster with our customers.

We are not only a digital manufacturer. Get in touch with us to find out how we create customized features and functional components to develop truly exceptional products.

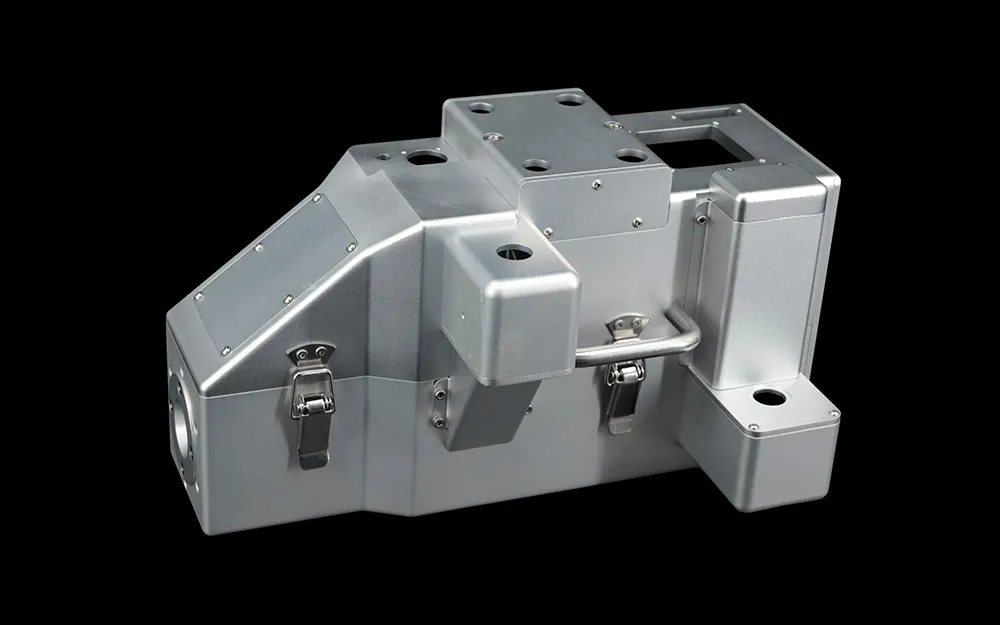

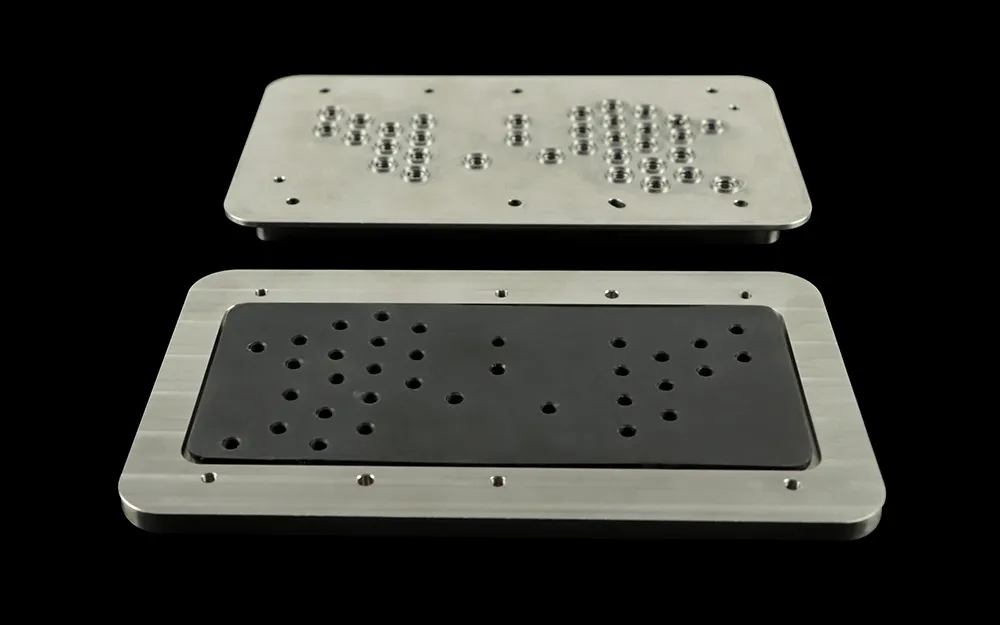

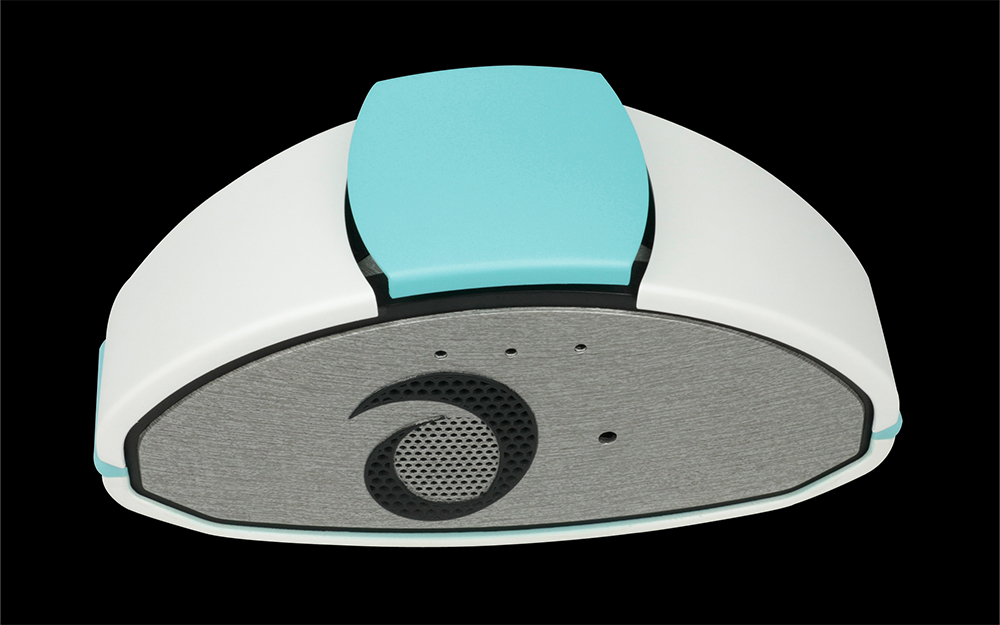

Examples of assembly and fitting

It takes skill to transform computer-designed parts into perfectly assembled products with multiple materials and technologies. But don’t just take our word for it—check out some of our completed projects.

Our main advantages in assembling

1. Endless options: Just be creative!

Explore an extensive array of material options, finishes, tolerances, markings, and outsourced components, encompassing millions of potential combinations. Our dedicated efforts ensure meticulous matching and coordination of these elements to create cohesive results every single time.

1. Endless options: Just be creative!

2. Comprehensive manufacturer and assembler: Just one contact

Receive fully assembled, ready-to-use parts and final products conveniently delivered to your doorstep, eliminating the need for you to handle the challenges of sourcing, project management, and logistics.

2. Comprehensive manufacturer and assembler: Just one contact

3. Quality assurance: Thorough pre-delivery checks

Our assembly service guarantees the delivery of high-quality parts that meet your expectations. We also offer custom physical and functional testing options, allowing you to thoroughly assess and validate your parts before they are shipped to you.

3. Quality assurance: Thorough pre-delivery checks

Our scope of services

Finishes

Project Process

Quality Control

FAQs about assembly and fitting

Can complex assemblies be achieved?

Yes, we are fully equipped to handle complex assemblies. With our extensive experience, we have successfully completed projects involving over 100 components made from various materials and utilizing multiple production methods. Thanks to our expertise, we apply the specific tolerances required by each technology to ensure precise and efficient assembly, even in demanding sectors such as aerospace and automotive.

Can Protolis assist in design for assembly (DFA)?

Our participation in Design for Assembly (DFA) is essential. It is a key step in our process, and we encourage you to share all relevant information and collaborate closely with us. Your input helps us better understand the interaction and functionality of the different parts, allowing us to propose optimizations and ensure that the final assembly perfectly meets your requirements and vision.

Do you offer to conduct functional tests on assembled products?

Absolutely, we do offer testing services for assembled products. Please provide us with detailed information about the functions and the testing criteria you require. Once we have this information, we will generate a comprehensive report complete with pictures and videos. Additionally, if needed, you can send us individual components for testing within the final assembly. We firmly believe in rigorous quality control and testing, every component and the assembly as a whole undergo meticulous testing to guarantee compliance with specified standards and functionality in real-world conditions.