Your trusted partner for rapid prototyping and manufacturing

- 200+ grade of materials and 8 production methods

- Single parts and multi-component assemblies

- Personalized support from our project managers

- Quote in 24 hours

- As fast as 7 days

Your project, our solutions

Partner with Protolis for rapid prototype production and low-volume manufacturing. From unique parts to complex assemblies, we offer custom solutions that combine speed and precision to bring your ideas to life.

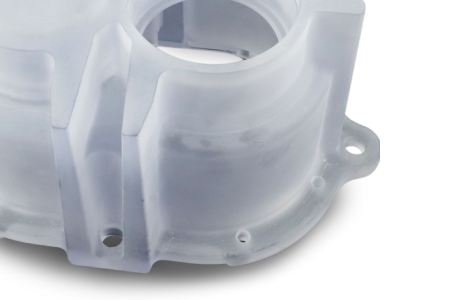

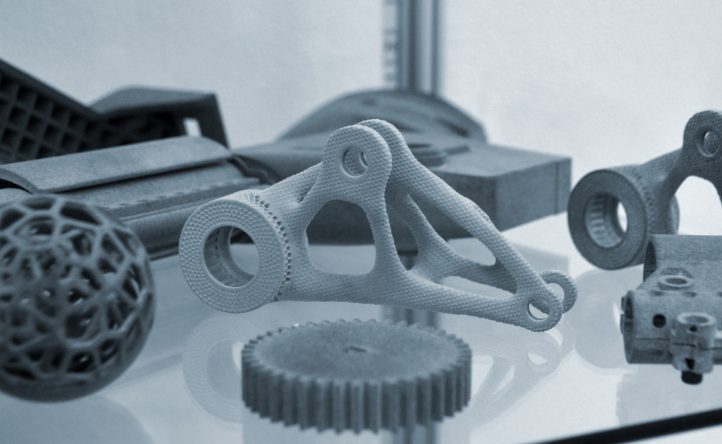

Choose your technology

We offer various different production methods to best suit your requirements. If your prototyping or low-volume production project needs several technologies and materials, we can recommend the ideal solution, ensuring precise fit and assembly of your final product.

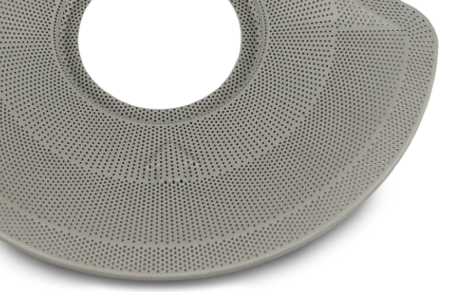

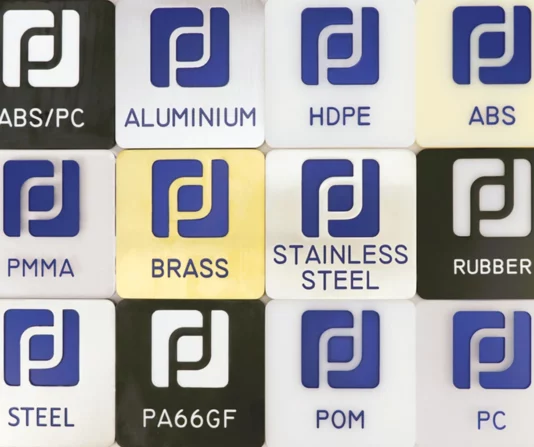

Choose your material

We offer a huge choice of plastic, metal, and elastomer materials to produce your parts with the exact properties you’re looking for. Prototyping and production grade materials are both available.

Choose your material

Choose your finishing

Surface finishing and treatment is the final step in the production of your prototype or end-use parts. We use various processes with the objective of improving the appearance, providing additional resistance, and more.

Choose your finishing

Your project in 5 steps

Get your plastic and metal prototypes or production parts in no time. Here’s how it works.

Your quote

Upload files

DFM

Design optimizations

Production

Close follow-up

Quality control

Dimensional report, pictures, and videos

Delivery

Packing, door-to-door tracking

Smart and agile services

Protolis is more than a subcontractor. Our passionate, experienced team understands our customers’ unique requirements and constraints—and works tirelessly to be a valuable partner and bring their products and innovations to life.

Smart support

Beyond manufacturing solutions, we provide smart, personalized support to our customers to ensure successful projects.

Wide capabilities

We provide access to a wide choice of production methods, materials and finishes, plus a fitting and assembly service.

Fast turnaround time

With our flexible and agile processes from quote to delivery, you can count on us to produce your parts in a timely manner.

Expertise in prototyping and low-volume manufacturing

Over the years, Protolis has become a trusted partner for prototyping and low-volume production of quality parts and assembly projects across various sectors. We understand the challenges of transitioning from prototyping to series production and are skilled in guiding our clients through the decisions that ensure the scalability of a product.

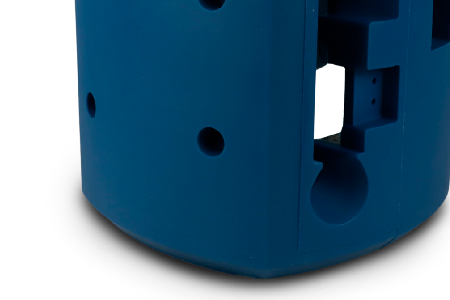

Prototyping

Prototyping or rapid prototyping describes the process of manufacturing, in the shortest time possible, a model with the maximum possible accuracy and with the intention to validate different aspects: visual, mechanical, functional, fitment and assembly, and more.

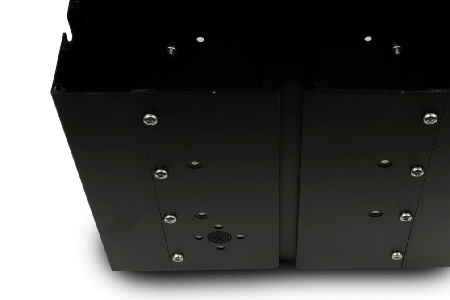

Low-volume production

Low-volume production describes the process of manufacturing quality parts up to a few thousands, with stable repeat accuracy. Usually, these parts require less design optimization compared to series production parts and need to be produced quickly.

Hear from our customers

Everything arrive on time and the finish is beautiful! The feel is as desired, soft and matte, appearance is neat, the fitting of inserts is good and the details have been respected, all in record time. Thank You!

Gael Lapierre

Cofounder – Elwing

Protolis has done an excellent job for my design studio. I was very satisfied with the finish of the complex parts made for my lamp prototypes. The compliance with my 3D models and the quality of finish are very professional. Fast delivery and very good protection.

Thomas Durantel

Director – Thomas Durantel Design

We received the parts within 10 days, which is very much appreciated. On receiving them, we were very surprised by the high-quality appearance. In fact, the part looked exactly like an injected part. These have also been sold in our pre-series.

Yoann Fourmond

General Manager – UniteckLatest news and resources

Extrusion Guide

Evolving roles of 3D printing and injection molding in modern manufacturing